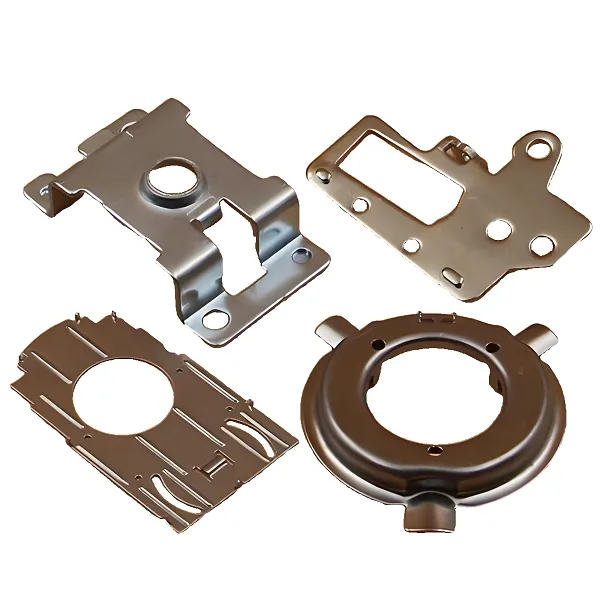

The “best” gauge for metal stamping depends on application needs, but 16 to 22 gauge (0.5–1.6mm thick) is widely preferred for its balance of formability, strength, and versatility. This range works with most materials (steel, aluminum, stainless steel), suits diverse operations (bending, punching, drawing), and meets requirements across industries like automotive, electronics, and consumer goods, ensuring cost-effective, high-quality production.

Detailed Analysis of the Best Gauges for Metal Stamping

1. Understanding Gauge: Thickness and Material Context

Gauge measures metal sheet thickness, with lower numbers indicating thicker material (e.g., 10 gauge = 3.4mm; 24 gauge = 0.7mm). The optimal gauge depends on balancing formability, strength, and manufacturing feasibility:

- Formability vs. Thickness: Thinner gauges (higher numbers) are easier to bend, draw, and punch due to lower material resistance. Thicker gauges (lower numbers) offer strength but require more force, limiting complexity.

- Material Compatibility: Ductile materials (aluminum, mild steel) handle a wider gauge range, while brittle materials (high-carbon steel) perform best in mid-range gauges to avoid cracking.

2. 16–22 Gauge (0.5–1.6mm): The Versatile Sweet Spot

This range dominates metal stamping for its adaptability to diverse applications:

-

Formability: 16–22 gauge materials balance rigidity and flexibility. For example, 18 gauge (1.0mm) mild steel bends easily into 90° angles with a 1×T radius, while 22 gauge (0.7mm) aluminum undergoes deep drawing for shallow cups without wrinkling. This makes the range ideal for complex shapes like brackets, enclosures, and automotive trim.

-

Strength: Sufficient for structural roles like electrical boxes (16 gauge steel) or appliance brackets (20 gauge aluminum), providing tensile strength of 300–500 MPa (mild steel) and 110–310 MPa (aluminum). It resists deformation under moderate loads, avoiding the flimsiness of thinner gauges.

-

Process Compatibility: Works with all stamping operations:

- Punching: Holes ≥1×T (e.g., 1mm hole in 1mm steel) are clean and burr-free, avoiding tool overload.

- Bending: Minimal springback in ductile materials, reducing the need for over-bending adjustments.

- Progressive Stamping: Feeds smoothly through automated lines, with consistent material flow for high-volume production (10,000+ parts/day).

-

Cost-Effectiveness: Thinner than 16 gauge reduces material usage and press force, lowering per-part costs. Thicker than 22 gauge avoids the fragility of ultra-thin sheets, reducing scrap rates from tearing.

3. Gauge Selection by Material

Different materials perform best in specific gauge ranges due to their unique properties:

-

Mild Steel:

- 16–20 gauge (1.0–1.6mm) is ideal for structural parts (brackets, frames) needing strength and formability.

- 20–22 gauge (0.7–1.0mm) suits automotive body panels and enclosures, balancing weight and durability.

- Thicker than 16 gauge (e.g., 14 gauge = 1.9mm) requires higher press tonnage but works for heavy-duty parts like machinery guards.

-

Aluminum Alloys:

- 18–24 gauge (0.5–1.0mm) excels for lightweight parts (aerospace brackets, heat sinks). 22 gauge (0.7mm) 3003 aluminum is easy to form into complex shapes with minimal tool wear.

- Thicker than 16 gauge (1.6mm+) aluminum can wrinkle during deep drawing, requiring careful die design and lubrication.

-

Stainless Steel:

- 18–22 gauge (0.8–1.2mm) balances corrosion resistance and formability for kitchen appliances and marine hardware. 20 gauge 304 stainless steel resists rust while bending into food-grade containers.

- Thicker stainless steel (16 gauge = 1.6mm) needs coated dies to prevent galling (material transfer), increasing tooling costs but suiting high-strength, corrosion-resistant parts.

-

Copper/Brass:

- 20–24 gauge (0.5–0.8mm) is preferred for electrical contacts and decorative parts, offering high conductivity and malleability for intricate stamping (e.g., terminal pins with fine features).

4. Industry-Specific Gauge Preferences

Gauge selection aligns with industry requirements for performance and cost:

-

Automotive:

- Body panels: 20–22 gauge mild steel or aluminum (0.7–1.0mm) for lightweighting and formability.

- Chassis brackets: 16–18 gauge mild steel (1.0–1.6mm) for strength to withstand vibration and load.

-

Electronics:

- Enclosures: 22–24 gauge steel (0.5–0.7mm) for thin, compact designs that shield against EMI.

- Heat sinks: 18–20 gauge aluminum (0.8–1.0mm) for thermal conductivity and easy forming of fins.

-

Construction:

- HVAC ducts: 24 gauge galvanized steel (0.5mm) for flexibility and corrosion resistance.

- Structural brackets: 16 gauge mild steel (1.6mm) to support building loads.

-

Consumer Goods:

- Appliance trim: 20–22 gauge stainless steel (0.8–1.0mm) for scratch resistance and aesthetics.

- Cookware: 18 gauge aluminum (1.0mm) with a stainless steel clad, balancing heat distribution and durability.

5. Challenges with Extreme Gauges

Ultra-thin or thick gauges introduce unique difficulties, making the 16–22 range preferable for most applications:

-

Thinner than 22 Gauge (<0.7mm):

- Prone to wrinkling during bending or drawing, requiring tight die clearances (0.01–0.03mm) and vacuum-assisted feeding in automated lines.

- Low rigidity may cause part distortion post-stamping, needing additional stiffening features (ribs, flanges) that complicate design.

-

Thicker than 16 Gauge (>1.6mm):

- Requires higher press tonnage (e.g., 50 tons for 16 gauge vs. 30 tons for 20 gauge steel), increasing energy costs and limiting equipment compatibility.

- Higher risk of tool wear, especially in hard materials like stainless steel, necessitating expensive carbide dies or coatings.

- Reduced formability: Bending thick steel may cause cracking without pre-annealing, adding process steps and cost.

6. Gauge Selection Guidelines

To choose the best gauge, follow these practical steps:

- Define Function: Structural parts need thicker gauges (16–18), while lightweight/complex parts use 20–22.

- Check Material Formability: Brittle materials (high-carbon steel) avoid gauges <18 to prevent cracking.

- Consider Production Volume: High-volume runs favor 18–22 gauge for efficient feeding and lower scrap rates.

- Balance Cost: Thicker gauges increase material and energy costs; thinner gauges risk higher scrap from tearing.

In summary, 16–22 gauge (0.5–1.6mm) is the best range for metal stamping, offering the ideal mix of formability, strength, and cost-effectiveness. It adapts to diverse materials and industries, ensuring reliable production of high-quality parts from automotive components to electronics enclosures.