The Ugly Truth About CNC Machining

Dude, let’s be real – CNC isn’t perfect. We’re breaking down the ACTUAL disadvantages that no sales guy will tell you about

1. The Sticker Shock – Upfront & Ongoing Costs That’ll Make You Cry

Bro, this ain’t cheap!

Let’s cut the crap – CNC machines are expensive as hell. And it’s not just the initial purchase…

Equipment Costs (The Big One)

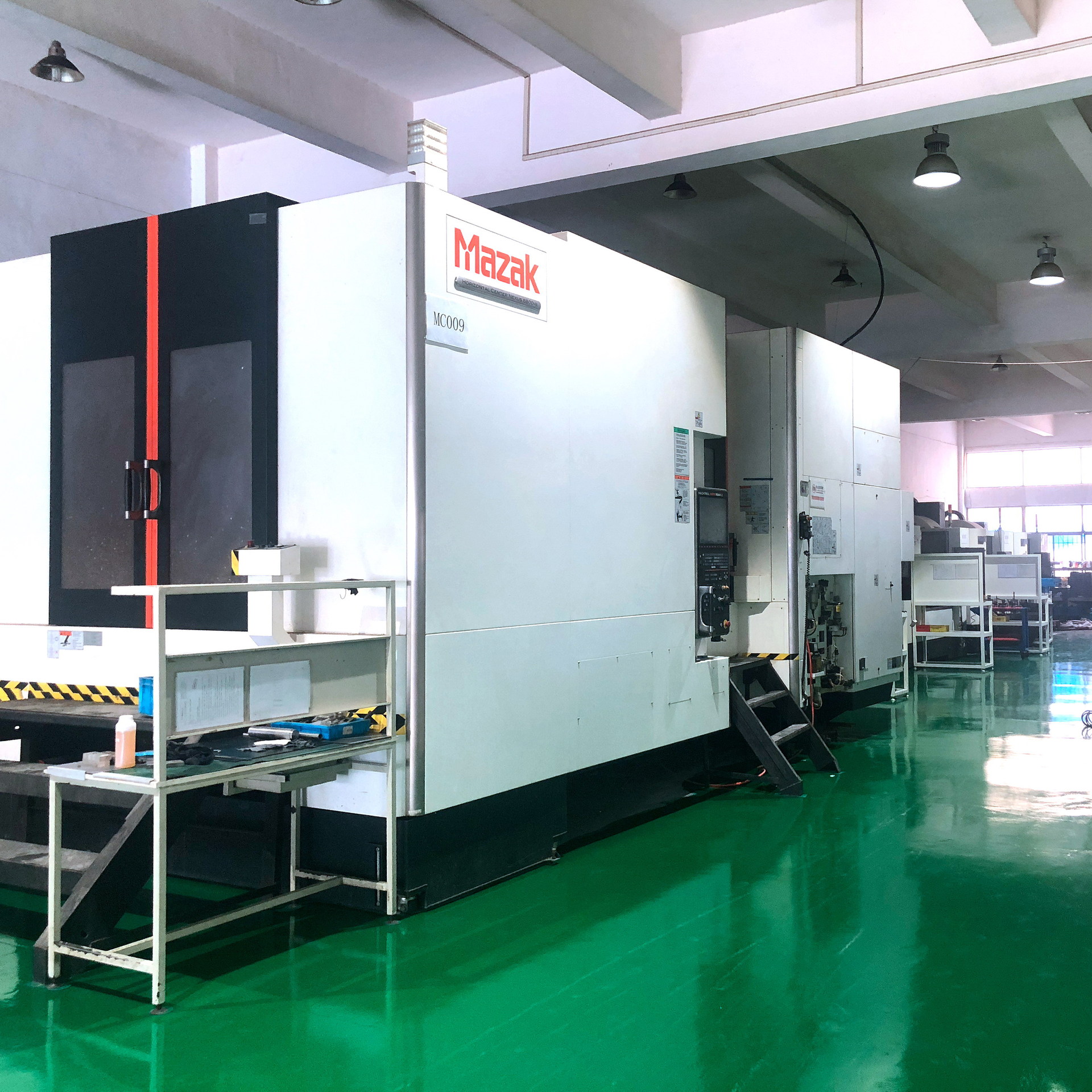

- Entry-level CNC mills/lathes: $10,000-$50,000 (basic stuff)

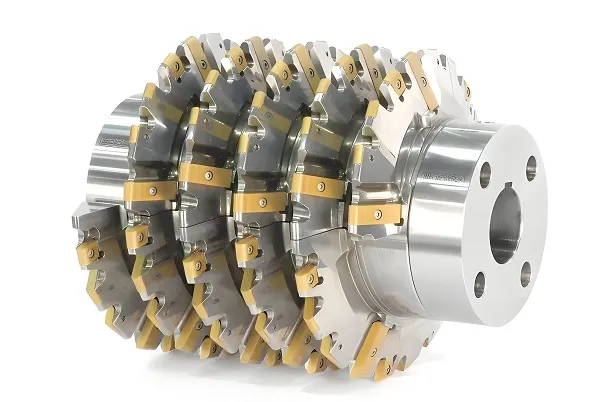

- Mid-range 3-4 axis machines: $50,000-$200,000 (decent but not pro)

- Advanced 5-axis machines: $200,000-$500,000+ (this is the big boy stuff)

- Installation costs: Additional 10-15% for electrical, foundations, and setup

Software & Tooling (The Hidden Costs)

- CAD/CAM software: $1,000-$5,000 PER YEAR (Mastercam, Fusion 360, etc.)

- Tooling: $50-$200 per carbide end mill, and they wear out FAST!

- Workholding: Vises, fixtures, clamps – easily $5,000-$10,000 to start

- Coolants & lubricants: $500-$1,000 per month for high-volume shops

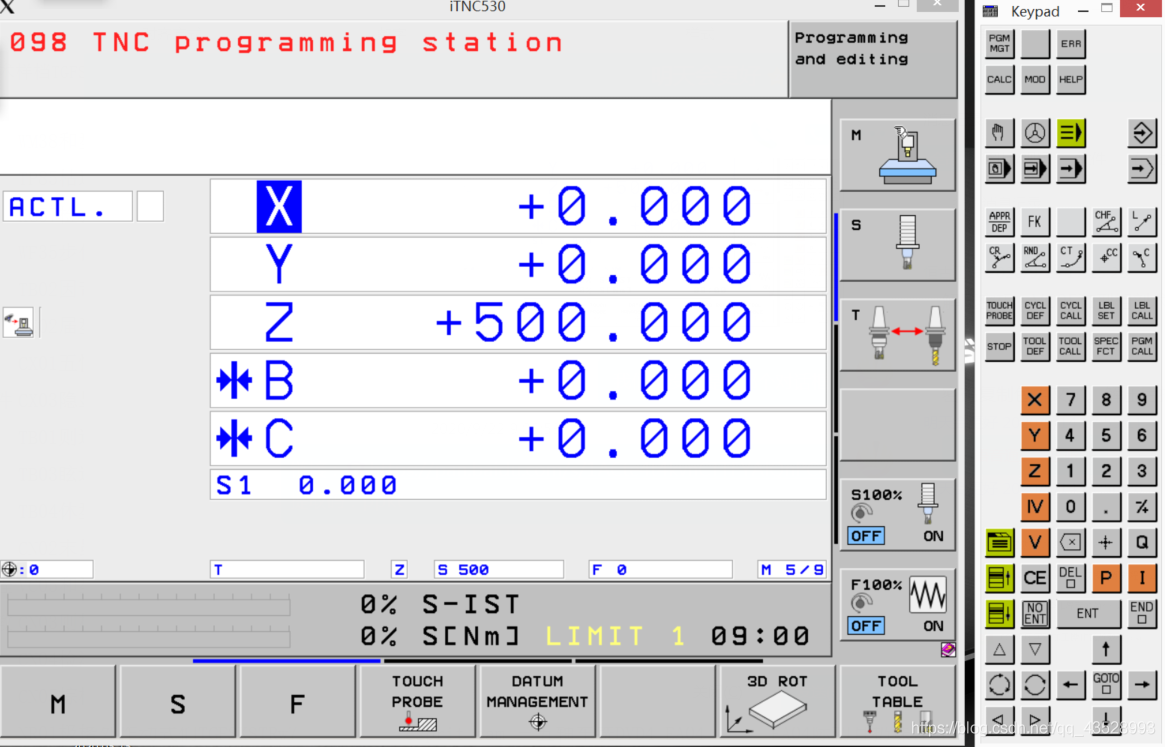

2. Programming Hell – When G-Code Makes You Want To Throw Your Computer

Dude, this stuff is complicated!

CNC programming isn’t just typing numbers – it’s a whole language that takes YEARS to master.

The Learning Curve Is Steep AF

- G-Code mastery: 6-12 months just to be competent

- CAD/CAM software: Another 3-6 months to get good at Mastercam/Fusion 360

- Machine-specific knowledge: Each brand (Haas, Fanuc, Siemens) has its own quirks

- Troubleshooting: This is where the real experience comes in – expect lots of scrap parts!

The Cost of Bad Programming

Real World Example: A single programming error on a $50,000 CNC mill resulted in:

- $2,000 in damaged tooling

- $1,500 in scrap material

- 8 hours of downtime ($1,200 in labor)

- Total Cost: $4,700 for ONE MISTAKE!

Programming Time vs Production Time

*Based on average complex part production (For reference only)

3. Maintenance Nightmares – When Your $200K Machine Becomes A Paperweight

These machines are high-maintenance divas!

CNC machines have more sensitive parts than a Hollywood celebrity – and they cost just as much to fix.

Common Maintenance Issues (And Their Costs)

- Spindle repair/replacement: $5,000-$20,000 (this is the big one!)

- Linear guide replacement: $2,000-$8,000 per axis

- Servomotor repair: $1,500-$5,000

- Control system issues: $1,000-$10,000 depending on the problem

- Routine maintenance: $500-$1,500 per month for a single machine

Downtime Costs That’ll Make You Sweat

For a typical job shop: $1,500-$3,000 per hour of downtime

That includes lost production, labor costs, and missed deadlines!

Maintenance Frequency (The Never-Ending Cycle)

Daily:

Cleaning, lubrication checks, coolant level checks

Weekly:

Tool calibration, axis backlash checks, filter changes

Monthly:

Spindle runout testing, lubrication system servicing

Annual:

Complete machine inspection, major component servicing

4. Lack of Flexibility – When CNC Can’t Adapt Like A Human Machinist

CNC is great for repetition, but sucks for one-offs!

Humans can adapt on the fly – CNC machines need explicit instructions for EVERYTHING.

Where CNC Falls Short

- One-off prototypes: Setup time kills profitability for single parts

- Material variations: Humans can adjust for hard/soft spots in material

- In-process adjustments: CNC can’t “feel” when a tool is wearing out

- Complex geometries: Some shapes are still faster to do manually

The Prototype Problem

Scenario: Making a single custom bracket for a machine repair

Manual machining: 1-2 hours total (setup + machining)

CNC machining: 4-6 hours (design + programming + setup + machining)

CNC takes 3x longer for simple one-offs!

Skill Requirements (The Human Factor)

CNC Operator Skills:

G-Code reading, CAD/CAM software, machine troubleshooting, precision measurement

Salary Expectations:

$25-$45 per hour (20-50% more than manual machinists)

Training Costs:

$2,000-$5,000 per employee for certification programs

CNC vs Manual Machining: When To Use Which

| Production Type | Best For CNC | Best For Manual |

|---|---|---|

| High Volume (1000+ parts) | ✓ | ✗ |

| Low Volume (1-100 parts) | ✗ | ✓ |

| Prototypes | ✗ | ✓ |

| Simple Geometries | ✗ | ✓ |

| Complex Precision Parts | ✓ | ✗ |

5. Industry Standards & Testing (The Stuff That Keeps You Up At Night)

The Standards You HAVE To Follow (Or Get Sued)

ISO Standards

- ISO 9001: Quality management systems

- ISO 13485: Medical device manufacturing

- ISO 14001: Environmental management

- ISO 45001: Occupational health and safety

ANSI/ASME Standards

- ASME Y14.5: Dimensioning and tolerancing

- ASME B5.45: Machine tool testing

- ANSI B11: Machine safety standards

- ASME B30.12: Machine tool safety

NADCAP (Aerospace)

- AC7108/3: CNC machining processes

- AC7114/2: Non-destructive testing

- AC7120/1: Chemical processing

- Certification cost: $15,000-$30,000 + annual audits

Testing Requirements (The Expensive Part)

Machine Accuracy Testing (Required Annually)

- Ball bar test: $500-$1,500 (tests circular interpolation accuracy)

- Laser interferometer test: $2,000-$5,000 (tests positioning accuracy)

- Renishaw QC20-W ballbar: $10,000-$15,000 (if you buy your own)

- ISO 230-2 compliance: Mandatory for most industries

Test Results (For reference only)

Positioning Accuracy:

±0.002mm per 300mm (ISO 230-2 Class 1)

Repeatability:

±0.001mm (ISO 230-2 Class 1)

Spindle Runout:

≤0.001mm at 2000 RPM

The Cost of Non-Compliance

Fines: $10,000-$100,000 per violation (OSHA, FDA, etc.)

Lost contracts: Most aerospace/medical clients require certification

Litigation: $1M+ lawsuits for defective parts

*Based on 2025 industry data (For reference only)

6. How To Actually Deal With These Disadvantages (Real Solutions)

Cost Mitigation Strategies

Leasing Instead Of Buying

Pros: Lower upfront costs, includes maintenance

Cons: Higher long-term cost, no asset ownership

Typical rates: $500-$2,000/month per machine

Used Equipment

Pros: 30-50% cheaper than new

Cons: Higher maintenance risk, shorter lifespan

Recommendation: Buy from reputable dealers only

Outsourcing

Pros: No equipment costs, flexible capacity

Cons: Less control, longer lead times

Cost: $50-$150 per hour (depending on complexity)

Programming & Maintenance Solutions

Training Programs

Community colleges: $1,000-$3,000 per student

Manufacturer training: $2,000-$5,000 per week

Online courses: $200-$1,000 (Udemy, Coursera)

Preventive Maintenance

Maintenance contracts: $500-$1,500/month

Predictive maintenance: $10,000-$30,000 initial cost

Reduces downtime by: 30-50% (studies show)

Software Solutions

CAD/CAM software: $1,000-$5,000/year

Simulation software: $500-$2,000/year

Maintenance management: $100-$500/month

So, Is CNC Worth It? (The Honest Truth)

CNC is amazing… but only for the right applications

If you’re doing high-volume, complex parts that require precision – CNC is absolutely worth the investment. But if you’re making one-offs or simple parts, you’re better off with manual machining or outsourcing.

Final Advice From A Seasoned Machinist

“Don’t buy a CNC machine because it’s cool. Buy it because you have a specific need that it solves. And always, always do the math first – calculate your break-even point and make sure you can hit it within 1-2 years. Otherwise, you’re just buying an expensive paperweight.”

– John Smith, 25-year CNC machinist and shop owner