The biggest problem with 3D printing right now is speed vs. quality trade-offs. Most consumer and mid-range printers take hours or even days to create complex parts, and if you try to speed things up, you often sacrifice precision or surface finish. It’s a major hurdle for scaling production beyond small-batch manufacturing.

Tech Basics

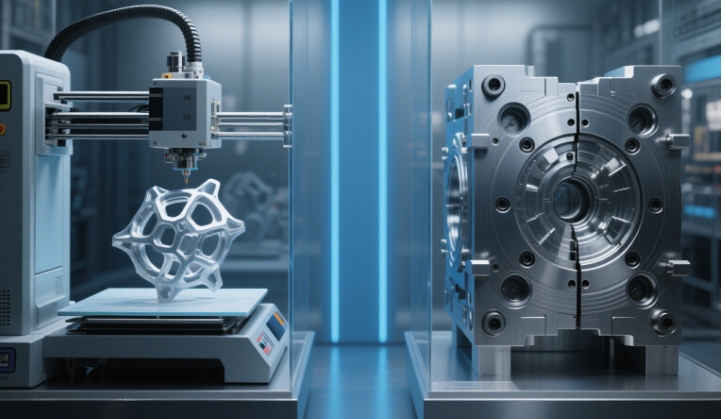

3D printing builds objects layer by layer using digital models, a process called additive manufacturing. Unlike traditional subtractive methods (cutting material away), it minimizes waste. Common technologies include FDM (melting plastic filaments), SLA (curing resin with light), and SLS (sintering powders with lasers), each with unique speed and precision strengths.

Material Limits

While materials have expanded beyond basic plastics, options are still narrower than traditional manufacturing. Metals, composites, and biocompatible materials exist but are pricier and require specialized printers. Many materials also lack the strength or heat resistance needed for industrial parts, limiting high-performance applications.

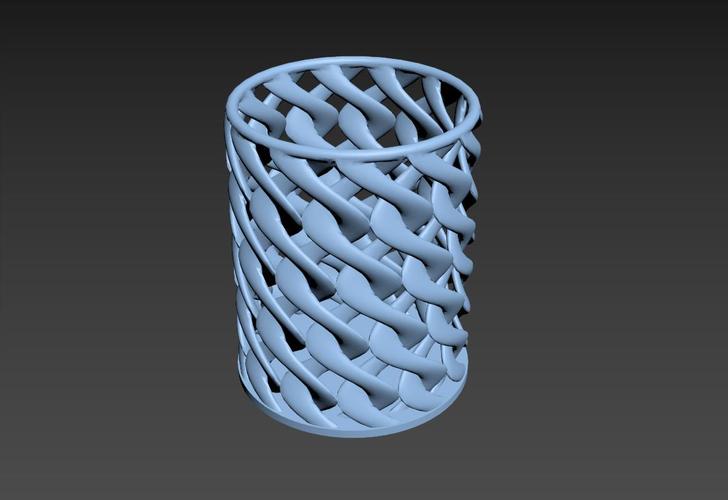

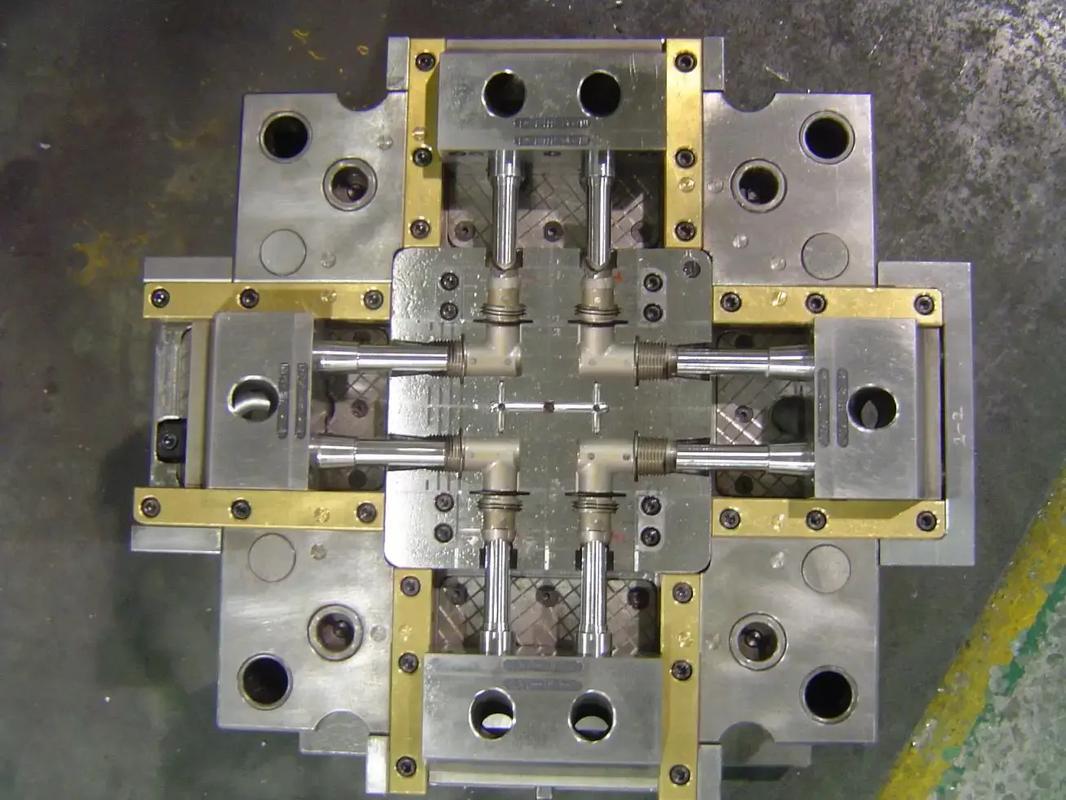

Customization Power

The biggest perk? Unmatched customization. 3D printing lets you create one-of-a-kind designs without expensive molds or tooling. From personalized jewelry to custom prosthetics, it’s ideal for products tailored to specific needs, making mass customization finally feasible for small businesses.

Streamlined Process

The workflow is surprisingly straightforward: design a 3D model (using software like CAD), slice it into layers with printing software, load the material, and hit print. Post-processing (sanding, painting, or curing) may be needed, but it’s far simpler than traditional manufacturing’s multiple production steps.

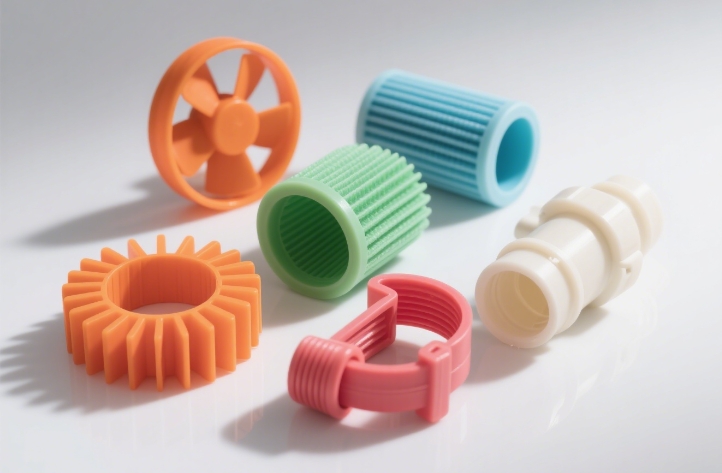

Real-World Uses

Applications span industries: healthcare uses it for patient-specific implants; aerospace for lightweight, complex parts; and fashion for unique accessories. Hobbyists love it for prototypes and custom gadgets, while educators use it to bring 3D concepts to life in classrooms.

Data-Driven Design

3D printing thrives on digital data. Models can be shared instantly online, and designs can be optimized using AI to reduce weight or improve strength—all before the first layer is printed.

Curious how 3D printing could transform your project or business? Drop a question below, and our team at https://www.xmgoldcattle.com/ will help you explore the possibilities!