Cheapest Materials for CNC Machining in 2026 – Cost, Machinability & Trade-offs

Looking to cut CNC prototyping or production costs? The “cheapest” material isn’t always the lowest raw price – machining time & tool wear often dominate (up to 70% of total cost).

Material Comparison

Aluminum, Brass & Stainless Steel CNC Machined Parts

Plastic vs Metal CNC Parts

Black plastic and silver aluminum CNC machined components

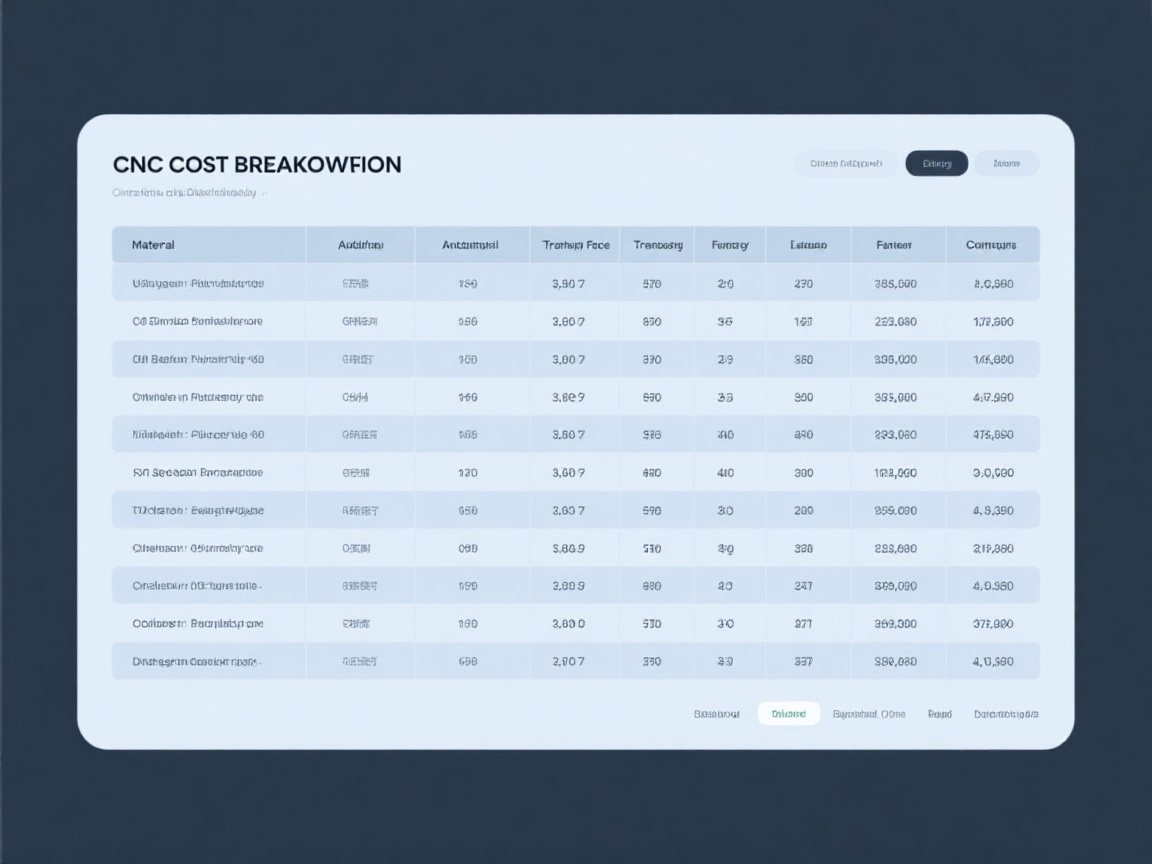

CNC Cost Breakdown

Material (30%) vs Machining (50%) vs Other (20%)

2026 CNC Material Cost Comparison

Real Cost Breakdown Example

Same Part: 100×50×20mm Block

ABS Plastic

Aluminum 6061

Steel 1018

Material Deep Dive

When NOT to Choose the Cheapest

Plastic in High Temperature/Load Applications

Plastic may seem cheap upfront, but it can fail catastrophically in high temperature or load-bearing applications, leading to expensive rework and downtime.

Better choice: Aluminum or stainless steel

Steel in Corrosive Environments

Mild steel rusts quickly in humid or corrosive environments, requiring expensive plating or frequent maintenance that negates initial cost savings.

Better choice: Stainless steel or anodized aluminum

Low Strength Materials for Safety-Critical Parts

Using cheap, low-strength materials for safety-critical components can lead to failures, injuries, and liability issues that far exceed material cost savings.

Better choice: Engineering-grade materials