CNC (Computer Numerical Control) machines are versatile, computer-driven tools designed to automate precision manufacturing processes. Their core purpose is to shape, cut, drill, or form materials with exceptional accuracy—far beyond what manual machining can achieve. Below is a detailed breakdown of their key applications across industries:

1. Metalworking

CNC machines are indispensable in metal fabrication, handling tasks like:

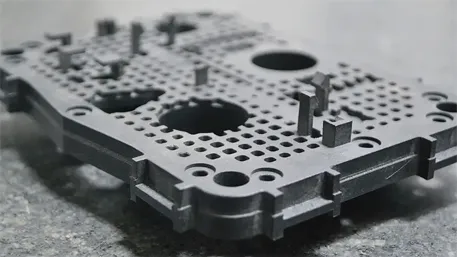

- Milling: Creating complex 3D shapes, slots, or threads in metals (e.g., aluminum, steel, titanium) using rotating multi-axis tools. CNC mills produce parts ranging from simple brackets to intricate aerospace components.

- Turning: Spinning cylindrical workpieces (e.g., shafts, bolts) while a stationary tool cuts, shapes, or grooves the material. CNC lathes are critical for producing symmetric parts with tight tolerances (often within ±0.001 inches).

- Grinding: Achieving ultra-smooth surfaces or precise finishes on metal parts, such as bearing races or mold inserts, using abrasive wheels controlled by CNC programs.

2. Plastic and Composite Machining

CNC machines excel at processing non-metallic materials, including:

- Plastics: Cutting, drilling, or routing plastic sheets (e.g., acrylic, PVC) for products like medical device housings, consumer electronics casings, or automotive interior components. The precision of CNC ensures consistent fits for assembly.

- Composites: Machining materials like carbon fiber or fiberglass, which require specialized tools to avoid delamination. CNC’s controlled movements prevent damage to these high-strength, lightweight materials.

3. Woodworking and Furniture Production

In woodworking, CNC machines streamline the creation of:

- Custom furniture parts: Carving intricate designs, joinery (e.g., dovetails), or 3D reliefs on wood, plywood, or MDF. This automation reduces manual labor while ensuring repeatability for mass production.

- Cabinetry and fixtures: Cutting precise panels, holes, or edges for kitchen cabinets, office furniture, or retail displays, with software allowing easy customization of sizes and styles.

4. Aerospace and Defense

The aerospace industry relies on CNC machines for manufacturing:

- Aircraft components: Turbine blades, engine parts, or structural frames made from heat-resistant alloys. CNC’s ability to hold tight tolerances (down to microns) is critical for safety and performance.

- Military hardware: Precision parts for weapons systems, drones, or armor, where even minor errors could compromise functionality.

5. Medical Device Manufacturing

CNC machining is vital for producing medical tools and implants due to strict material and accuracy requirements:

- Surgical instruments: Stainless steel scissors, forceps, or drills, machined to avoid sharp edges that could damage tissue.

- Implants: Titanium hip replacements or dental crowns, where CNC ensures a perfect fit with the patient’s anatomy.

6. Prototyping and Rapid Manufacturing

CNC machines accelerate product development by quickly producing prototypes from metal, plastic, or wood. Unlike 3D printing, CNC prototypes use the same materials as final products, providing accurate tests of strength, fit, and functionality.

Why is CNC machining irreplaceable?

Its key advantages—precision (repeatable to 0.0001 inches), automation (24/7 operation with minimal oversight), and versatility (handling materials from foam to superalloys)—make CNC machines essential in industries where quality, consistency, and efficiency are non-negotiable. Whether for mass production or one-off custom parts, CNC machining delivers results that manual methods or other technologies struggle to match.