Answer

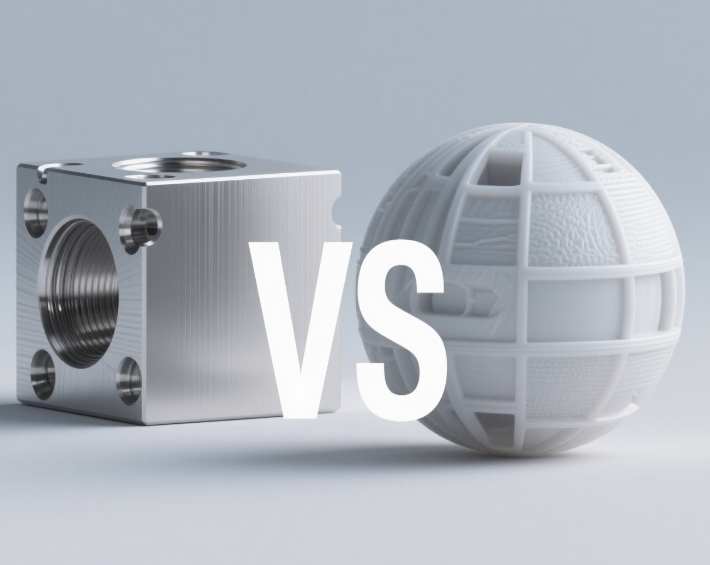

The core difference between metal embossing and stamping lies in forming effects and process objectives: Embossing creates concave-convex textures (like patterns, letters) via local plastic deformation for surface decoration, while stamping shapes metal globally with dies to manufacture structural parts (e.g., casings, components) for functional purposes. The former is mostly shallow relief, and the latter enables deep drawing or complex structures.

Extended Response (Six Key Aspects)

1. Process Principles & Forming Goals

- Embossing:

- Uses concave-convex patterns on upper/lower dies to apply local pressure on metal surfaces, causing shallow plastic deformation to form relief patterns (protrusion height typically ≤0.5mm).

- Aims for decorative effects (e.g., leather texture, logos) or functional textures (e.g., anti-slip grooves), without changing the part’s overall shape.

- Stamping:

- Applies overall pressure to metal sheets via presses and dies, inducing plastic deformation or separation (e.g., punching, bending, drawing) to form 3D-structured parts (e.g., car panels, battery cases).

- Aims to achieve functional structures meeting mechanical requirements like strength and dimensions.

2. Die Design & Complexity

| Comparison Dimension | Embossing | Stamping |

|---|---|---|

| Die Structure | Mostly single-process simple dies (e.g., punch + die, pattern accuracy ±0.05mm) | May include compound dies (punching + bending) or progressive dies (multi-process continuous forming) |

| Die Material | Commonly tool steel (e.g., Cr12MoV, hardness HRC 58–62) | Thick-plate stamping requires cemented carbide (e.g., YG8) for higher wear resistance |

| Typical Die Cost | Single die: ~$70–$700 (e.g., phone case texture die) | Complex progressive die: $14,000–$700,000 (e.g., automotive panel die) |

3. Material Suitability & Thickness Range

- Embossing:

- Suits ductile metals (e.g., copper, aluminum, stainless steel sheets), typically 0.1–2mm thick (thicker materials blur patterns).

- Examples: 0.3mm aluminum watch dial embossed with scales, 0.5mm brass embossed bookmarks.

- Stamping:

- Wider material range (including carbon steel, titanium alloy), thickness 0.1–10mm (hydraulic presses for thick plates).

- Examples: 2mm steel stamped into motor casings, 0.1mm copper strips stamped into precision terminals.

4. Precision Requirements & Surface Effects

- Embossing:

- Lower dimensional accuracy (±0.1mm) but high pattern clarity (e.g., letter stroke width ±0.03mm), burr-free surface suitable for appearance parts.

- Common effects: Coin relief, notebook cover metal logos, kitchenware anti-slip patterns.

- Stamping:

- Higher structural accuracy (general ±0.1mm, precision stamping ±0.03mm), but edges may have burrs (needing post-treatment), and surfaces may scratch due to die wear.

- Example: Mobile phone mid-frame stamping accuracy ±0.05mm, requiring secondary polishing.

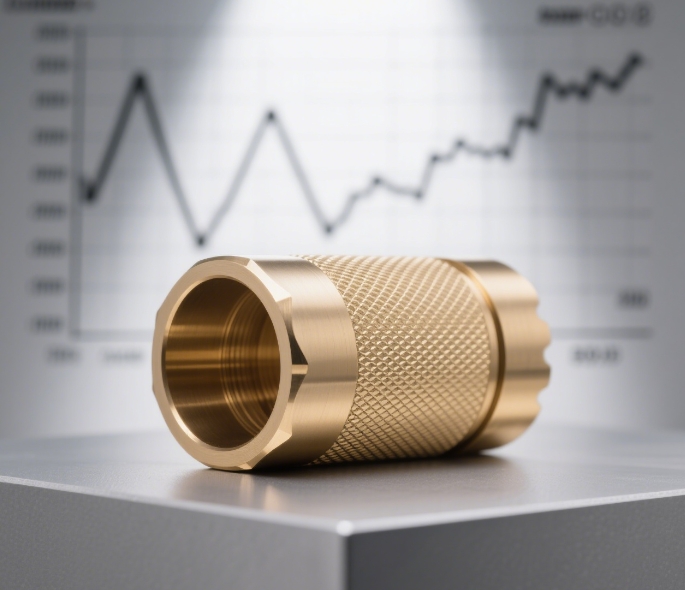

5. Production Efficiency & Application Scenarios

- Embossing:

- High single-process efficiency, small embossing machines reach 200–500 strokes/min, suitable for medium-small batch decorative parts (e.g., souvenirs, packaging metal labels).

- Typical applications: Jewelry patterns, electronic device nameplates, credit card raised letters.

- Stamping:

- High-speed presses reach 1,000 strokes/min (e.g., continuous terminal stamping), suitable for mass-produced structural parts (e.g., automotive components, appliance casings).

- Example: New energy vehicle battery cover stamping (1M units/year), one-step drawing of refrigerator liners.

6. Equipment & Cost Differences

- Embossing:

- Uses small embossing machines (10–50 tons), low investment ($7,000–$28,000), suitable for small-batch multi-variety production (e.g., customized nameplates).

- High material utilization (≥95%) as minimal material is removed.

- Stamping:

- Requires presses matched to material thickness (20–2,000 tons), large equipment investment (e.g., automotive stamping lines cost tens of millions), suitable for mass production to reduce costs (shared costs).

- Complex stamping (e.g., deep drawing) may generate scrap, material utilization ~70%–85%.

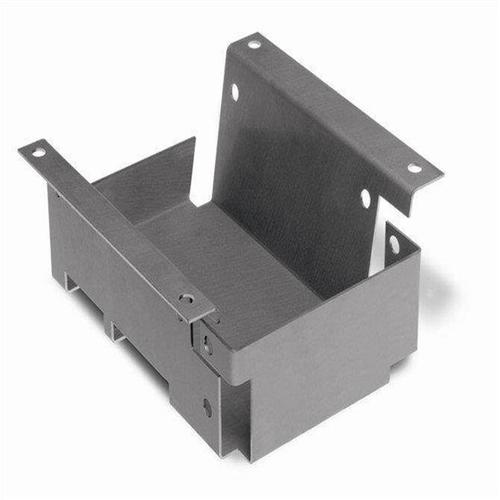

7. Process Combination & Post-Treatment

- Embossing + Stamping:

- Some parts are first stamped then embossed (e.g., mobile phone metal back covers: stamped into arcs → embossed with anti-slip textures).

- Post-Treatment Differences:

- Embossed parts often directly undergo electroplating or painting (to protect patterns);

- Stamped parts may require annealing (stress relief), deburring, surface hardening (e.g., quenching), etc.