- Answer

In CNC machining, the most difficult materials to process are usually super – hard alloys (such as tungsten steel, titanium alloy), ceramic materials (such as zirconia, silicon carbide), and high – temperature alloys (such as nickel – based alloys). These materials have extremely high hardness (Rockwell hardness can reach above HRC60), strong wear resistance, and are prone to generating high temperatures during processing, resulting in severe tool wear. Special processes and equipment are required for their processing.

- Explanation (A vivid and simple metaphor)

Processing these materials is like “carving on granite with a pencil”:

Super – hard alloys: They are like “metal – version diamonds”. Their hardness is close to that of rocks. When milling with ordinary tools, it’s like cutting steel with a wooden knife, and the cutting edge will wear out rapidly (similar to scratching glass with a plastic ruler).

Ceramic materials: They are like “fragile glass bricks”. They are so hard that they can scratch metals, but are likely to crack during processing (similar to hitting glass with a hammer, which will shatter into pieces if too much force is applied).

High – temperature alloys: They are like “heat – generating plasticine”. During processing, the material softens due to high temperatures and sticks to the tool, just like chewing gum sticking to the sole of a shoe, which is difficult to clean, and can also “burn” the tool.

- Problem Expansion

Core Reasons for Difficulty in Processing and Coping Technologies

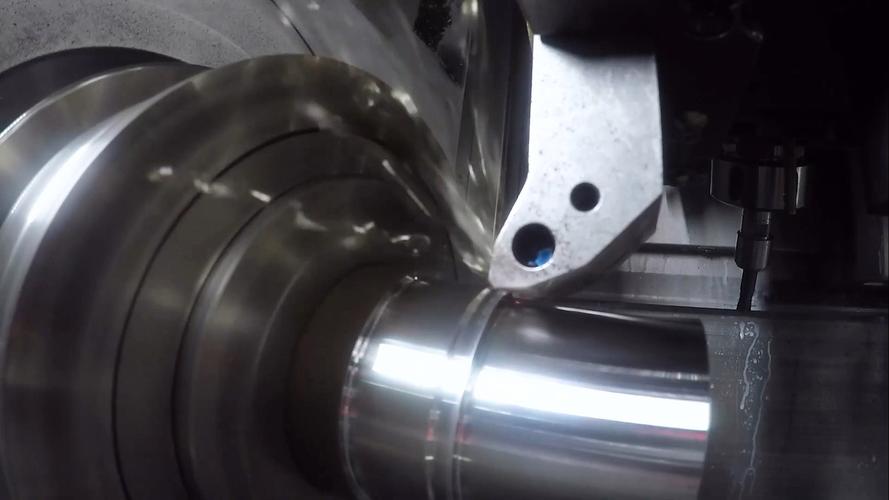

Super – hard alloys (such as tungsten steel)

Difficulties: The hardness reaches HRC80 (three times harder than ordinary steel), and the thermal conductivity is poor. During processing, heat concentrates on the tool edge, causing the blade to wear out quickly (the lifespan is only 1/10 of that for ordinary steel).

Solutions:

Use cubic boron nitride (CBN) tools or diamond – coated tools, whose hardness is close to that of natural diamonds (HV3000+).

Adopt slow feed + high – pressure cooling, for example, the feed rate is only 0.1mm per minute, and at the same time, use liquid nitrogen spraying for cooling.

Application scenarios: Processing cemented carbide molds (such as the inner hole of drawing dies), aerospace engine nozzles.

Ceramic materials (such as silicon carbide ceramics)

Difficulties: The hardness reaches HV2000 (second only to diamonds), but they are brittle, and micro – cracks are likely to occur during processing (similar to carving ice with a knife, which will crack if the force is uneven).

Solutions:

Use electrical discharge machining (EDM) or ultrasonic vibration cutting, reducing stress concentration through high – frequency vibration.

Pre – heat the material to 300℃ before processing to reduce brittleness (similar to heating glass before cutting).

Application scenarios: Electronic packaging substrates (requiring high – precision holes), ceramic bearing rings.

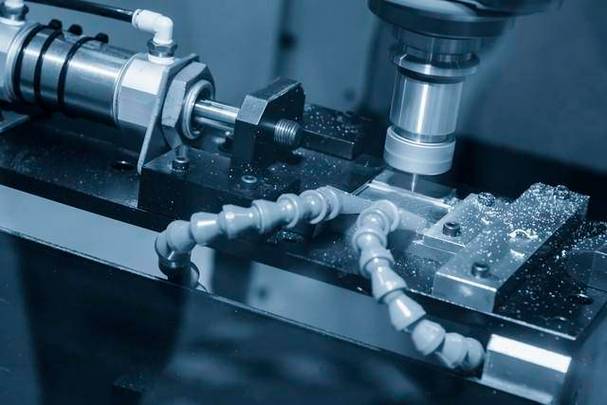

High – temperature alloys (such as Inconel 718 nickel – based alloy)

Difficulties: It still maintains high strength above 600℃. During processing, the material has high viscosity and is likely to form a “built – up edge” on the rake face of the tool (similar to dough sticking to a rolling pin), resulting in a sudden increase in cutting force and deterioration of surface roughness.

Solutions:

Use coated cemented carbide tools (such as TiAlN coating, which can withstand high temperatures up to 1100℃).

Adopt a trochoidal milling path to reduce the contact time between the tool and the material and avoid overheating (similar to quickly combing through knotted hair with a comb to reduce pulling force).

Application scenarios: Aero – engine turbine blades (required to withstand 1200℃ high temperature), high – pressure valves in nuclear power plants.

Future Breakthroughs in Processing Technologies

Laser – assisted machining: First, use a laser beam to locally soften the super – hard material, and then cut with a tool, with an efficiency increase of 5 times (such as the laser – CNC composite machine tool of the Fraunhofer Institute in Germany).

Nano – coated tools: Through multi – layer nano – films (such as AlCrN/VN coating), the tool life can be extended to 8 times that of traditional tools, and it has been used in the medical field to process titanium – alloy artificial joints.

The processing challenges of these materials drive the development of cutting technologies towards “harder, cooler, and smarter”. Each breakthrough means an upgrade in manufacturing in cutting – edge fields such as aerospace and precision medicine.