In the modern manufacturing industry, CNC machine tools have become indispensable processing equipment due to their high precision, high efficiency, high degree of automation and other characteristics. So, what parts can be processed by CNC machine tools? The following will be a detailed answer.

1. The processing range of CNC machine tools

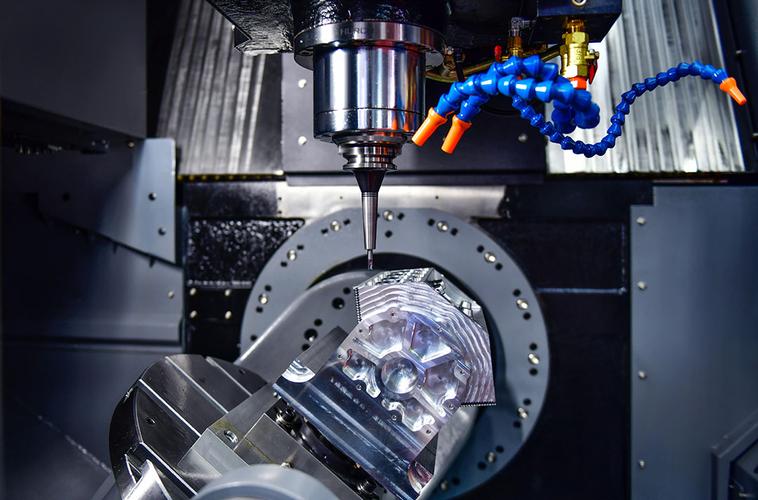

CNC machine tool is a pre-written CNC program to control the tool’s trajectory and processing parameters of the machine tool. Because of its high degree of flexibility and programmability, CNC machine tools are able to process a variety of shapes, materials and sizes of parts.

Parts with different shapes

Shaped parts: such as brackets, forks and other irregularly shaped parts. These parts often require mixed machining in multiple stations, which CNC machines can easily handle.

Curved parts: the surface of parts composed of complex curves or surfaces, which require multiple axes to be linked for machining. CNC machines are able to meet the requirements of these parts for highly centralized process and assembly accuracy.

Plane type and parts with hole system: parts with parallel machining surfaces or consistent angles with the horizontal plane, such as parts with keyways or end faces with distributed hole systems. CNC machine tools can be processed according to different spindle movements.

Variable oblique angle parts: the machining surface and the angle of the horizontal plane is a continuous change in the parts, such as some parts of the aircraft and inspection fixtures.

Parts made of different materials

Metallic materials: the most commonly processed materials by CNC lathes, including steel, iron, aluminum, copper, zinc, etc., as well as special materials such as titanium alloys, nickel-based alloys, high-temperature alloys and so on.

Non-metallic materials: such as plastics, ceramics, etc. CNC lathes are equally capable of processing these materials to meet the needs of specific industries.

Parts of different sizes

Miniature parts: CNC machine tools are capable of tiny machining, realizing the production of miniaturized parts with high precision.

Large parts: CNC machine tools are capable of processing a wide range of materials and can also handle large parts.

2. CNC machine tools in various fields of application

Mechanical manufacturing field: CNC machine tools have a wide range of applications in the field of mechanical manufacturing, can process a variety of shafts, disks, shells and other parts to improve processing efficiency and processing quality.

Aerospace field: As the aerospace field requires high precision and quality of parts, CNC machine tools have become indispensable equipment in this field. It can process complex aviation engine blades, aircraft structural components and other key components.

Automobile manufacturing industry: automobile manufacturing process requires a large number of high-precision parts, such as engine blocks, crankshafts, connecting rods and so on. CNC machine tools play an important role in the manufacture of automotive parts with its high precision and high efficiency.

Mold manufacturing industry: mold is an important tool in the manufacturing industry, CNC machine tools can process mold cavities, cores and other key components to ensure the accuracy and life of the mold. At the same time, CNC machine tools can also achieve rapid manufacturing and modification of molds to improve the efficiency and quality of mold manufacturing.

Other fields: CNC machine tools are also widely used in medical equipment, electronic manufacturing, energy, construction, furniture manufacturing and other fields for processing high-precision, high-quality medical equipment parts, electronic equipment parts, oil drilling equipment, building structural parts, furniture parts and so on.

Summarize

With its high precision, high efficiency, high degree of automation and high flexibility, CNC machine tool is capable of processing parts of various shapes, materials and sizes. It has a wide range of applications and important contributions in many fields such as machinery manufacturing, aerospace, automobile manufacturing, mold manufacturing and so on. With the continuous development of science and technology, the application areas of CNC machine tools will continue to expand and deepen, providing more powerful support for the development of modern industry.

Through the above answers, we can clearly understand the processing range of CNC machine tools and their wide application in various fields.