This webpage provides a detailed overview of end milling, covering its definition, cutter types, applications, benefits, challenges, considerations, differences from face milling, and related services. Below is a comprehensive summary:

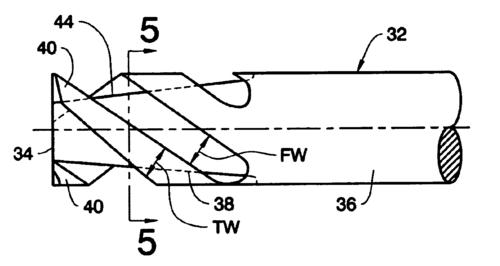

- Definition: End milling is a subtractive manufacturing process using rotating cutters with helical cutting edges to remove material and form complex features on workpieces made of metals, plastics, composites, and other engineering materials. Unlike other tools, end mills have helical cutting edges on both the sides and ends of their cylindrical shanks, enabling multi-directional cutting.

- Key Terminologies:

- Shank: The cylindrical part clamped into the machine’s spindle.

- Neck: A reduced-diameter section for deeper reach.

- Flute: Helical grooves forming the cutting edges.

- Cutting Diameter: The widest diameter of the cutting edges.

- Helix Angle: The angle between the flute and the cutter’s centerline.

| Type |

Characteristics |

Applications |

| Roughing End Mills |

Wavy edges, large core diameter for heavy material removal (rougher finish). |

Heavy-duty machining of steel, aluminum, and iron (e.g., molds, shipbuilding, automotive pre-finishing). |

| Ball End Mills |

Hemispherical tip for 3D contouring and curved surfaces. |

Mold/die machining, automotive/aerospace parts, and filleting complex designs. |

| Corner Rounding End Mills |

Radius at the cutting edges for rounded corners. |

Deburring, filleting, and aesthetic finishing of edges. |

| Square End Mills |

Flat, square tip for 90° edges and flat surfaces. |

Slots, keyways, external contours, and flat-bottom holes. |

| Dovetail End Mills |

Angled edges (45°, 60°, 90°) for dovetail profiles. |

Dovetail joints, slots, and undercut features. |

| Finishing End Mills |

Sharp, fine-cutting edges for smooth surfaces (Ra 0.4 µm). |

High-precision parts in medical devices, heat sinks, and engine components. |

| V-bit End Mills |

V-shaped tip (30°, 60°, 90°) for engraving and chamfering. |

Engraving signs/logos, chamfering, and narrow cuts. |

| Material |

Characteristics |

End Mill Features |

Common Grades/Types |

| Aluminum Alloys |

Lightweight, easy to machine. |

High helix angles, polished flutes. |

6061, 7075, 2024 |

| Steel & Stainless Steels |

Strong, wear-resistant. |

HSS or carbide, TiCN coating. |

AISI 304, 316, 1018, 1045 |

| Titanium Alloys |

High strength, corrosion-resistant, hard to machine. |

Variable helix design, DLC coating. |

Grade 5 (Ti-6Al-4V), Grade 2 |

| Plastics |

Lightweight, prone to melting. |

Sharp edges, single/double flutes. |

Acrylic, PC, Nylon, Delrin |

| Composites |

Abrasive, risk of delamination. |

Compression end mills. |

CFRP, GFRP, Kevlar |

- Aerospace: Complex components like engine brackets and turbine cartridges (high-precision aluminum machining).

- Automotive: Engine parts, transmission housings, and EV components (motor elements, battery housings).

- Electronics: PCBs, enclosures, and thermal management parts (miniaturization and accuracy).

- Medical Devices: Implants, surgical tools, and diagnostic equipment (medical-grade titanium/stainless steel).

- Prototyping: Custom parts, molds, and fixtures in metals, plastics, and composites.

- Versatility: Performs cutting, plunging, profiling, and contouring.

- Precision: Tolerances as low as ±0.002 mm (standard: ±0.05 mm).

- Complex Geometry: Capable of 3D shapes via multi-axis machining.

- Reduced Finishing: As-machined surface roughness of 6.3–0.8 µm.

- Deep Cuts: Multi-flute design and coatings enable aggressive material removal.

| Challenge |

Solutions |

| Chatter & Vibration |

Use vibration dampers, secure clamping, and optimize cutting parameters. |

| Tool Breakage |

Optimize tool paths, monitor processes, and use coated cutters for hard materials. |

| Complex Setup |

Modular fixtures and CAM simulation for efficient alignment. |

| Heat Generation |

Coolants/lubricants, balanced feed/speed, and positive rake angles. |

| High Costs |

Quality tools, automation, and efficient tool paths to reduce waste. |

- Tool Material: HSS for soft metals/plastics; carbide (with TiN/TiAlN/DLC coatings) for hard materials.

- Flute Count: 2-flute for speed, 4-flute for finish and rigidity.

- Depth of Cut: Typically ≤50% of cutter diameter or flute length; 10–20% for fine finishes.

- Feed/Speed Optimization: Follow manufacturer guidelines or use online calculators.

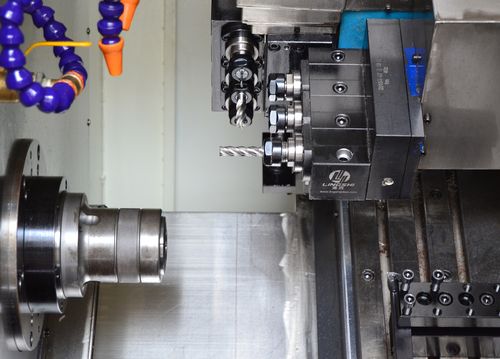

- Coolant/Lubrication: Flood cooling or MQL to reduce friction and heat.

- Tool Holder Balance: Static/dynamic balancing to minimize vibration.

- Regular Inspections: Monitor wear with real-time systems and replace tools proactively.

| Aspect |

End Milling |

Face Milling |

| Cutting Tool |

Small, with side/end edges. |

Large, flat, with face edges. |

| Movement |

Vertical/angled. |

Horizontal/flat. |

| Chip Formation |

Complex, discontinuous. |

Large, continuous. |

| Speed |

Lower. |

Higher. |

| Surface Finish |

Rougher (Ra 0.8–6.3 µm). |

Smoother (Ra 0.8–1.6 µm) for large flats. |

| Applications |

Details, slots, contours. |

Flattening, large surface finishing. |

| Ideal For |

Small parts, deep slots. |

Big flat surfaces. |

| Tool Life |

Longer with proper care. |

Shorter due to higher forces. |

- Offerings: Instant quotes, 20+ milling operations, custom tooling, prototyping/production, 100+ materials, and fast lead times.

- Clients: Suitable for startups and enterprises across industries, ensuring high-precision parts per design specifications.

End milling enables the production of intricate features with the right cutter, parameters, and setup. Understanding challenges like heat and vibration helps prevent defects. This process drives innovation in complex mechanical designs, enhancing manufacturing precision and efficiency across sectors.

-

What are the types of end mills? Flat, ball nose, roughing, finishing, corner radius, and V-bit mills.

-

How to choose an end mill? Consider material, cutting type (roughing/finishing), geometry, and machine capabilities.

-

End milling vs. drilling? End milling cuts axially and radially for slots/contours; drilling cuts only axially for holes.

-

Why “end” mill? Cuts from the tool’s end and sides, enabling multi-directional material removal.

-

Feed rate calculation? Feed = Spindle speed × Chip load per tooth × Flute count.

Let me know if you need further refinements!