Introduction: The Evolution of Woodworking CNC Technology

Woodworking CNC technology represents a revolutionary advancement in modern wood manufacturing, combining computer numerical control with traditional woodworking craftsmanship. This precision-driven approach enables high-accuracy machining of complex wood components while maintaining the natural beauty and structural integrity of wood materials.

Industry data highlights the growing importance of CNC woodworking:

- Market growth: Global woodworking CNC market projected to reach $8.2B by 2026 (CAGR 6.8%)

- Precision improvement: CNC machining reduces dimensional errors by 85% compared to traditional methods

- Efficiency gains: Automated production increases throughput by 300% for complex components

- Material optimization: CNC nesting software reduces wood waste by 40-50%

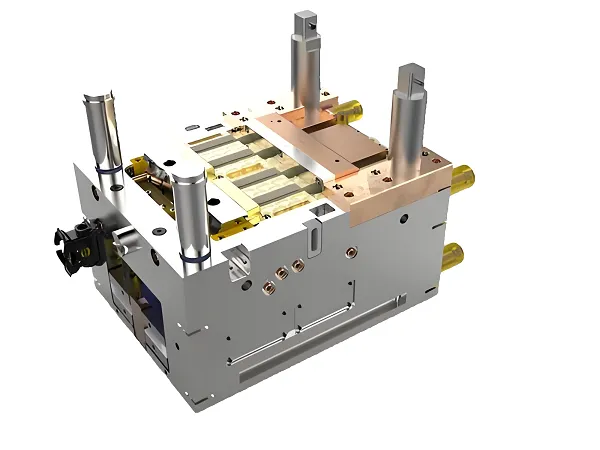

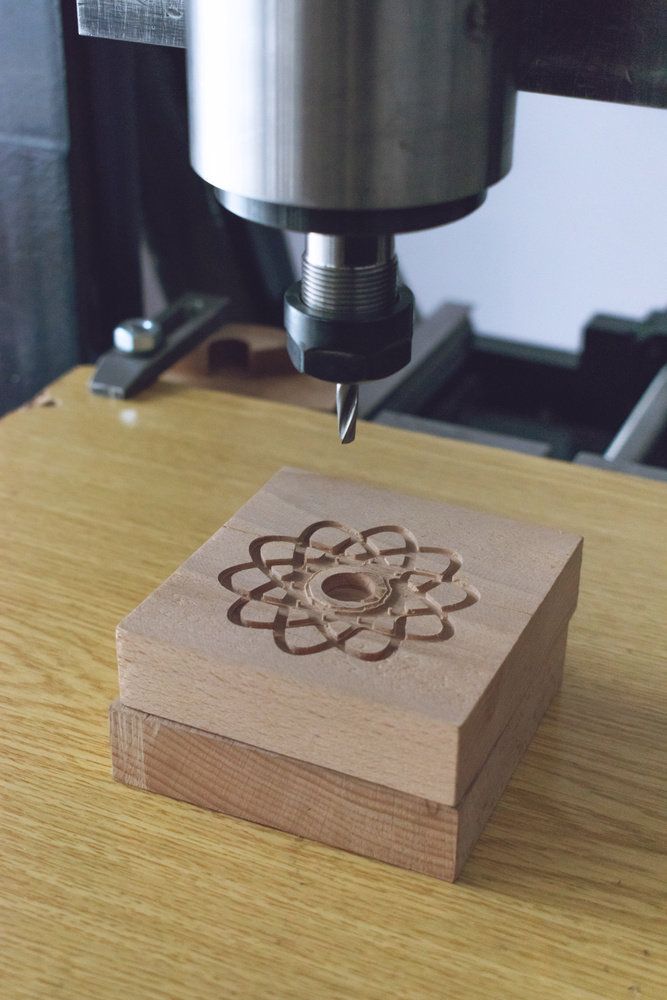

Precision CNC Wood Router Creating Intricate Carving Patterns

Quality Certifications & Industry Standards Compliance

ISO 9001:2015

Quality management system certification ensuring consistent product quality and customer satisfaction across all woodworking processes.

FSC Certification

Forest Stewardship Council certification for sustainable wood sourcing from responsibly managed forests.

ISO 19085-3:2021

Safety requirements for computer numerical control woodworking machinery, ensuring operator safety and machine reliability.

Compliance Verification Process

- Material certification: FSC chain-of-custody documentation for all wood materials

- Process validation: ISO 19085 safety protocols implemented on all CNC machines

- Quality audits: Quarterly ISO 9001 compliance assessments

- Performance testing: Annual machine accuracy verification according to ISO 7568 standards

2026 Woodworking CNC Trends & Goldcattle Advanced Practices

Sustainable Machining Integration

FSC-certified materials combined with recycling programs reduce carbon footprint by 30-40%.

* Waste reduction: 45% (Goldcattle 2025 sustainability report)

AI-Powered Path Optimization

Real-time adaptive toolpath adjustment based on wood grain analysis improves efficiency by 25%.

* Efficiency increase: 28% (2025 customer case study)

Customization Demand Growth

Personalized furniture and decorative components market growing at 45% annually.

* Custom projects: 62% of total volume (2025 data)

Regulatory Impact 2026

New EU and US regulations mandate sustainable sourcing and reduced emissions for wood products. Goldcattle’s compliance with FSC, PEFC, and ISO 14001 standards ensures market access across all regions.

Core Woodworking CNC Processes & Technologies

1. CNC Routing & Carving

High-speed spindle routers (12,000-24,000 RPM) create intricate 2D and 3D patterns on wood surfaces. Specialized bits include:

- Carbide end mills: For detailed carving and profiling

- V-bits: For decorative bevels and lettering

- Bullnose bits: For rounded edges and smoothing

- Flush trim bits: For pattern following and edge finishing

2. Precision Cutting & Milling

Multi-axis CNC machines perform accurate cutting operations:

- Panel sawing: 0.1mm precision for large sheet materials

- Dado cutting: For joinery and assembly features

- Profile milling: For custom edge treatments

- Pocket machining: For hardware installation recesses

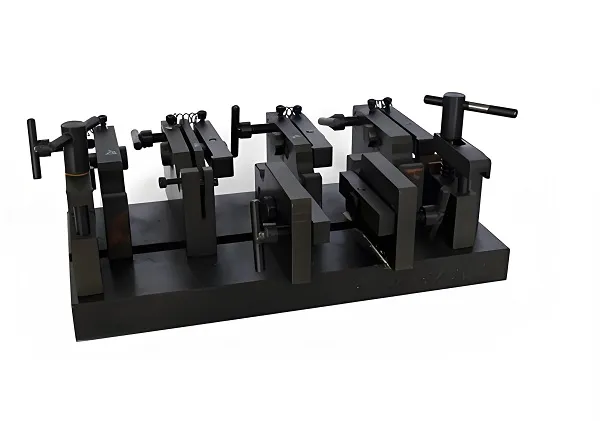

3. Drilling & Joinery

Precision drilling systems create accurate holes for hardware and joinery:

- Multi-spindle heads: For simultaneous hole drilling

- Depth control: ±0.05mm accuracy for blind holes

- Countersinking: For flush fastener installation

- Dowel hole drilling: For traditional joinery connections

4. Sanding & Finishing

Automated sanding systems prepare surfaces for finishing:

- Rotary sanding: For flat surfaces and edges

- Belt sanding: For material removal and leveling

- For intricate carved surfaces

- Dust collection: 99% efficiency for clean operations

Multi-pattern CNC Wood Carving with Precision Fixturing

Material Expertise & Sustainable Sourcing

Wood Material Categories

Hardwoods

- Maple: Fine grain, excellent for precision machining (Ra 1.2μm achievable)

- Oak: Durable, prominent grain patterns (requires specialized tooling)

- Cherry: Rich color, smooth machining characteristics

- Walnut: Dark color, excellent for decorative components

Softwoods

- Pine: Affordable, good for structural components

- Cedar: Natural resistance to decay, outdoor applications

- Douglas Fir: Strong, dimensional stability

Engineered Woods

- Plywood: Stable, cost-effective for large panels

- MDF: Uniform density, excellent for painting

- Particleboard: Economical, good for hidden components

Sustainable Sourcing Practices

Certified Supply Chain

- FSC certification: 100% of hardwoods from FSC-managed forests

- PEFC compliance: Additional certification for European markets

- Chain-of-custody: Complete documentation from forest to finished product

- Local sourcing: 65% of materials sourced within 500km radius

Environmental Impact Reduction

- Waste recycling: 95% of wood waste recycled into biomass fuel

- 30% energy reduction compared to traditional machines

- Water-based finishes: Zero-VOC coatings for indoor applications

- Carbon footprint: 45% reduction since 2020 (ISO 14064 verified)

Diverse Wood Material Selection Showing Different Grains and Finishes

Technical Specifications & Testing Data

Machining Capabilities

| Parameter | Capability | Tolerance |

|---|---|---|

| Positioning Accuracy | ±0.01mm | ISO 230-2 standard |

| Repeatability | ±0.005mm | After 100 cycles |

| Surface Roughness (Ra) | 1.2-3.2μm | Depending on material |

| Spindle Speed | 6,000-24,000 RPM | Variable speed control |

| Table Size | 1500×3000mm | Custom sizes available |

Testing & Quality Verification

Testing Procedures

- CMM inspection: Coordinate measuring machine for dimensional verification

- Surface profilometry: Ra value measurement using Mitutoyo SJ-210

- Material testing: Moisture content verification (6-8% optimal range)

- Adhesion testing: Pull-off strength for glued components

Performance Data

Goldcattle Testing Results (2025) *

Maple machining: Ra 1.2μm surface finish, ±0.008mm accuracy

Oak routing: Ra 2.8μm due to open grain structure

Plywood cutting: 0.012mm kerf width with 3mm blade

* Data for reference only, actual results may vary by material and complexity

Application Areas & Case Studies

Furniture Manufacturing

- Custom cabinet doors with intricate carvings

- Table legs with complex 3D profiles

- Chair components with precision joinery

- Bed frames with decorative headboards

* Case study: Luxury hotel furniture project (500+ pieces)

Architectural Millwork

- Interior wall panels with 3D textures

- Custom crown molding and trim

- Staircase components with safety features

- Door frames with decorative elements

* Case study: Commercial office building renovation

Decorative Components

- Wall art and decorative panels

- Custom signage and lettering

- Architectural models and prototypes

- High-end gift items and awards

* Case study: Museum exhibit fabrication project

Goldcattle Exclusive: Luxury Furniture Case Study

Project: Custom walnut dining table set for high-end residential client

Challenge: Create seamless 3D-carved table legs with hidden joinery

Solution: Used 5-axis CNC machining with specialized toolpath strategies

Results: ±0.005mm accuracy, Ra 1.6μm surface finish, 35% faster production than traditional methods

Quality Control & Inspection Procedures

Multi-Stage Quality Assurance

1. In-Process Inspection

- Real-time dimension verification using machine probes

- Tool wear monitoring and automatic compensation

- Material moisture content checks during machining

- Chip load optimization for each material type

2. Final Inspection

- Comprehensive CMM dimensional verification

- Surface roughness measurement using profilometer

- Visual inspection for defects and imperfections

- Assembly fit testing for mating components

3. Documentation & Traceability

- Digital quality records for each production batch

- Material certification and chain-of-custody documentation

- Machine performance logs and maintenance records

- Customer-specific quality reports as required

Equipment & Standards

Inspection Equipment

- Coordinate Measuring Machine: Mitutoyo Crysta-Apex S7106 (±0.0005mm accuracy)

- Surface Profilometer: Mitutoyo SJ-210 (0.01μm resolution)

- Digital Micrometers: ±0.001mm precision for dimensional checks

- Moisture Meters: Delmhorst J-2000 (0.1% resolution)

Compliance Standards

- ISO 9001:2015: Quality management system

- ISO 19085-3:2021: CNC woodworking machine safety

- ISO 7568:1986: Woodworking machine accuracy testing

- ASTM D1037: Standard test methods for wood-based panels

Quality Performance Metrics

First-pass yield: 98.7% (2025 average)

On-time delivery: 99.2% for all orders

Customer satisfaction: 4.9/5.0 rating

Diverse Wood Material Selection for Different CNC Applications

Frequently Asked Questions (2026 Update)

Q1: What types of wood are best suited for CNC machining?

A: The best woods for CNC machining include:

- Hardwoods: Maple, cherry, and walnut provide excellent detail and finish

- Softwoods: Pine and cedar work well for structural components

- Engineered woods: Plywood and MDF offer stability and cost benefits

Goldcattle Recommendation: For intricate carvings, use maple with 6-8% moisture content for optimal results.

Q2: What is the typical lead time for CNC woodworking projects?

A: Lead times vary based on project complexity and volume:

- Prototypes: 3-5 business days

- Small batches (1-50 pieces): 7-10 business days

- Medium production (51-500 pieces): 2-3 weeks

- Large production (500+ pieces): 4-6 weeks

Rush Service: Available for urgent projects with 30% premium.

Q3: How does CNC woodworking compare to traditional methods in terms of cost?

A: Cost comparison for a typical cabinet door project:

| Method | Labor Cost | Material Waste | Total Cost |

|---|---|---|---|

| Traditional | $150/hour | 25-30% | $280 per door |

| CNC Machining | $80/hour | 5-10% | $160 per door |

Cost Savings: CNC machining typically reduces costs by 35-45% for production runs over 50 pieces.

Q4: What file formats are accepted for CNC programming?

A: We accept the following file formats:

- CAD formats: DWG, DXF, STEP, IGES, SolidWorks (SLDPRT)

- Vector formats: AI, EPS, PDF (vector)

- Raster formats: JPG, PNG, TIFF (with minimum 300 DPI)

- 3D formats: STL, OBJ, 3DS

Best Practice: Provide native CAD files whenever possible for optimal results.

Q5: How do you ensure the sustainability of your wood materials?

A: Goldcattle’s sustainability program includes:

- FSC certification: 100% of hardwoods from responsibly managed forests

- Waste reduction: 95% of wood waste recycled into biomass energy

- Energy efficiency: Solar-powered manufacturing facilities

- Carbon neutrality: Offset remaining emissions through verified projects

Environmental Impact: Our processes reduce carbon footprint by 45% compared to industry averages.

Q6: What is the maximum size for CNC woodworking projects?

A: Our standard capabilities include:

- Maximum panel size: 1500×3000mm (5×10 feet)

- Maximum thickness: 150mm (6 inches)

- 3D machining depth: 200mm (8 inches) in multiple passes

Large Projects: For oversized components, we offer section machining with precise joining techniques.

Get Your Free Woodworking CNC Consultation

Are you planning a woodworking project and unsure about the best CNC approach? Need assistance with material selection, design optimization, or cost estimation?

Free Goldcattle Expert Services:

- ✓ Project feasibility assessment

- ✓ Material selection recommendations

- ✓ Design optimization for CNC machining

- ✓ Cost estimation and production planning

- ✓ Sustainability impact analysis

Final Thought: The Future of Woodworking CNC

Woodworking CNC technology represents the perfect marriage of traditional craftsmanship and modern precision engineering. As we move into 2026 and beyond, the integration of AI, sustainable practices, and advanced materials will continue to transform the industry. Goldcattle remains committed to pushing the boundaries of what’s possible with CNC woodworking, delivering exceptional quality while minimizing environmental impact.