As a national high – tech enterprise, Xiamen Goldcattle Industrial & Trading Co., Ltd. (official website: https://www.xmgoldcattle.com/) has become a trusted injection mold customization expert for global customers with its 26 – year experience in precision manufacturing. From microfluidic chip molds for medical equipment to multi – material connector molds for the automotive industry, from micro – precision molds in the electronics field to high – longevity mass – production molds for industrial scenarios, Xiamen Gold Cattle takes “high precision, fast delivery, full customization” as its core, and has built a full – chain service system covering mold design, R & D, production, inspection, and assembly, providing customers in various industries with solutions that combine technological depth and cost advantages.

I. Technical Strength: Solidifying Quality Foundations with Precision Equipment and Material Science

The core competitiveness of injection molds starts with the ultimate pursuit of “precision”. Relying on world-leading processing equipment and material innovation, Xiamen Golden Bull controls mold tolerances to the industry’s top level, laying a solid foundation for product consistency and stability.

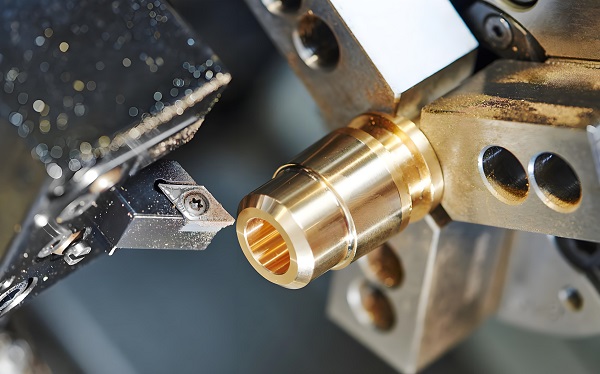

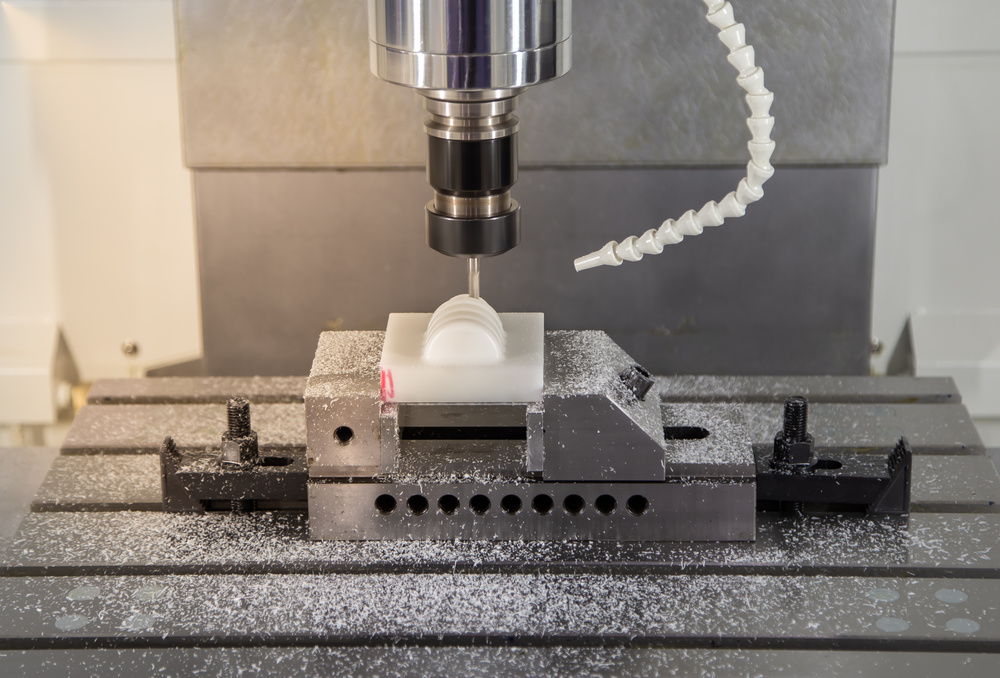

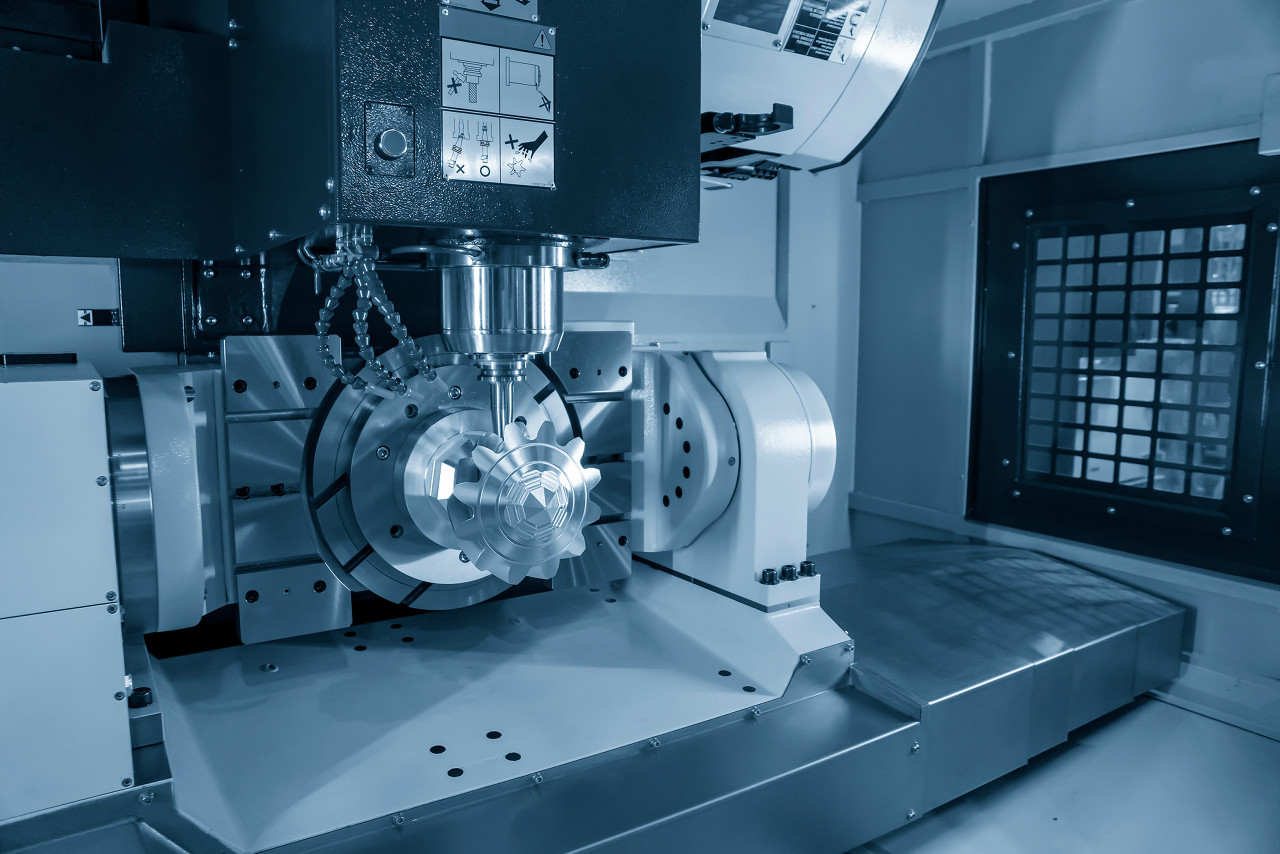

1. Top-Tier Equipment Cluster for Micron-Level Precision Control

The company is equipped with over 100 sets of high-end processing equipment. Among them, 5-axis CNC machining centers (such as DMG MORI HSC 75 Linear and Mazak 5-axis models) achieve a precision of ±0.001mm, enabling efficient processing of mold cores and cavities with complex structures; micro-EDM (Mitsubishi MV1200S) can handle micro-gear tooth profiles with a module of <0.1mm, controlling tolerance within ±0.0015mm; laser texturing machines (GF AgieCharmilles Laser S) can achieve surface textures with Ra 0.05-12.5μm, meeting the strict appearance and texture requirements for cosmetic casings and medical devices. In addition, online Coordinate Measuring Machines (CMM) monitor processing precision throughout the process, ensuring zero deviation between mold cavities, cores, and design drawings, and laying a “zero-defect” foundation for subsequent injection production.

2. Material Science Innovation: Balancing Performance and Cost

Targeting application scenarios in different industries, Xiamen Golden Bull has established a segmented mold steel selection system to achieve “on-demand matching and optimal performance”:

H13 Steel: After cryogenic treatment, its hardness reaches HRC 48-52, with a thermal conductivity of 24.3 W/m·K, extending mold lifespan by 15%. It is suitable for high-temperature injection-molded parts in the automotive industry (e.g., components around the engine).

S136 Steel: Boasting excellent corrosion resistance, its mirror polishing precision can reach Ra≤0.01μm, meeting the hygiene requirements for medical devices (e.g., infusion set components) and food-contact parts.

NAK80 Steel: With a pre-hardened hardness of HRC 40-43, it requires no subsequent heat treatment, making it suitable for optical lenses, high-precision electronic casings, and other scenarios sensitive to deformation.

Cost-Effective Options: P20 Steel (HRC 28-32, suitable for small-batch production with <100,000 cycles) and 718H Steel (HRC 34-38, suitable for mass production with >300,000 cycles) help customers find the optimal balance between cost and lifespan.

3. Simulation and Process Optimization: Reducing Mold Trial Costs

With the help of Ansys Moldflow thermal simulation technology, Xiamen Golden Bull can predict the warpage rate of products during injection molding with an accuracy of 92.3%, reducing the number of traditional mold trials (usually over 5 times) to ≤2 times, significantly shortening the R&D cycle. Through algorithm-driven generative design, it reduces steel usage by 18-25% while increasing mold fatigue strength by 15%, lowering material costs and reducing mold weight.

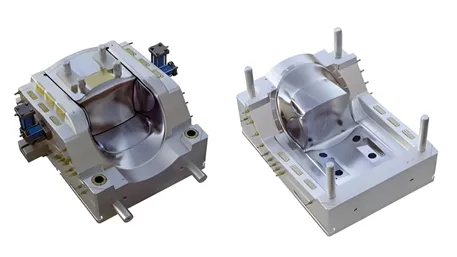

II. Customized Services: Addressing Industry Pain Points with Scenario-Specific Solutions

As an integrated OEM/ODM factory, Xiamen Golden Bull penetrates core industries such as medical care, automotive, electronics, and industrial equipment. It develops “tailor-made” custom injection mold services for the unique needs of different industries, solving customers’ full-process pain points from prototype verification to mass production.

1. Industry-Specific Empowerment Covering High-Difficulty Scenarios

Medical Industry: Focusing on ISO 13485 compliance requirements, it develops microfluidic chip molds and titanium insert injection molds. Through micron-level alignment technology with ±5μm precision, it achieves leak-proof sealing of sterile medical parts, meeting the ISO Class 7 cleanroom production standards.

Automotive Industry: It provides multi-material connector molds (tolerance ≤±0.005mm) and gas-assisted injection molding handle molds for Tier 1 suppliers. Supporting stable molding of engineering plastics such as PP and PA66 + glass fiber, the molds can achieve 3 million cycles of lifespan, adapting to the mass production needs of the automotive industry.

Electronics and Consumer Industry: It develops micro-injection molds (tolerance ≤±0.02mm) for core components of smart watches and micro-sensor casings. Supporting thin-wall molding (wall thickness ≤0.5mm) and two-color injection molding, it achieves the design goal of “small size and high integration”.

Industrial Equipment Industry: It customizes gearbox casing molds and pipe fitting molds. Adopting wear-resistant coatings (e.g., PVD coatings) and optimized cooling systems, it reduces product deformation caused by mold temperature differences and improves the durability of industrial parts.

2. Fast Delivery System: Seizing Market Opportunities

Xiamen Golden Bull deeply understands that “time is competitiveness” and has established an efficient delivery mechanism:

72-Hour Prototype Molds: It provides aluminum test molds (capable of producing 50-100 samples), which are 65% faster than the industry average delivery speed, helping customers quickly complete design verification and market research.

Standard Projects: 20-35 Days: Through a standardized project management process, the whole process from drawing confirmation to mold delivery is controllable.

Emergency Projects: 10-15 Days: For urgent needs such as new product launches and equipment maintenance, it activates a priority production channel to shorten the cycle of key processes.

3. Cost Control Solutions: Reducing Total Cost of Ownership (TCO)

Through modular design and intelligent inventory management, Xiamen Golden Bull helps customers significantly reduce costs:

Modular Mold Kits: Reusable bases and standard parts reduce custom costs for new projects by RMB 12,000-35,000.

RFID Intelligent Inventory: Real-time tracking of steel blanks shortens the material procurement cycle to 48 hours, avoiding inventory backlogs.

Whole-Process Waste Reduction: Optimizing mold structures (e.g., hot runner systems) reduces plastic waste rate by 15%, saving a large amount of raw material costs during long-term mass production.

III. Quality and Compliance: Building a Trust Barrier with International Certifications and Data-Driven Management

Xiamen Golden Bull regards “quality” as the lifeline of the enterprise. Through international certifications, full-process inspection, and data-driven management, it ensures that every set of molds meets the strict standards of global customers.

1. Comprehensive Coverage of Authoritative Certifications

The company has obtained ISO 9001:2000 quality management system certification, and its products comply with international standards such as SGS, CE, RoHS, FDA, and LFGB. Among them, medical molds additionally meet ISO 13485 compliance requirements, and toy molds pass safety certifications such as EN 71, ASTM F963, and CPSIA, enabling direct access to global markets in Europe, America, Japan, and South Korea.

2. Data-Driven Quality Control

In 2024, the first-time mold trial success rate of Xiamen Golden Bull reached 97.7%, far exceeding the industry average of 78-85%. This achievement stems from “full-process data traceability”: from raw material flaw detection (ensuring no internal defects in steel), to dimension inspection after rough machining, and hardness testing after heat treatment (ensuring HRC compliance), every step has data records. Before final delivery, VDI 3400 Class A1 optical inspection is conducted to ensure the mold surface reaches optical-level perfection.

3. Long-Term Lifespan Guarantee

Based on different mold materials and processes, Xiamen Golden Bull provides mold options with 500,000-3,000,000 cycles: micro-molds (aluminum) are suitable for small-batch prototype production; steel molds (e.g., H13, 718H) can support large-scale mass production; some high-end molds using powder metallurgy steel even exceed 3,000,000 cycles, providing stable guarantees for customers’ long-term production.

IV. Customer Value: From “Mold Supplier” to “Manufacturing Partner”

Over the past 26 years, Xiamen Golden Bull has always adhered to the principles of “high quality, high efficiency, and integrity service” and the goal of “customer-centric and sustainable operation”. It not only provides customers with mold products but also becomes an important partner in their industrial chain. Up to now, the company has served more than 500 global customers, helping them reduce the total cost of ownership (TCO) by an average of 18-22% through technical optimization. From high-temperature molds for aerospace-grade PEEK materials to automotive mass-production molds with millions of cycles, Xiamen Golden Bull’s solutions always bridge the gap between “innovative design” and “manufacturability”.

Whether it is a startup needing rapid prototype verification or a multinational group pursuing the stability of large-scale mass production, Xiamen Golden Bull can provide one-stop injection mold services “from design to assembly” with 26 years of technical accumulation, production capacity supported by over 100 sets of high-end equipment, and a 94.7% first-time mold trial success rate.

Cooperation Inquiry

Contact Person: Charlie Cheer

Tel: +86-18150097490

Email: charlie@plasticmetalparts.com

Official Website: https://www.xmgoldcattle.com/

Xiamen Golden Bull, working with you to build a “more precise, more efficient, and more competitive” manufacturing future.