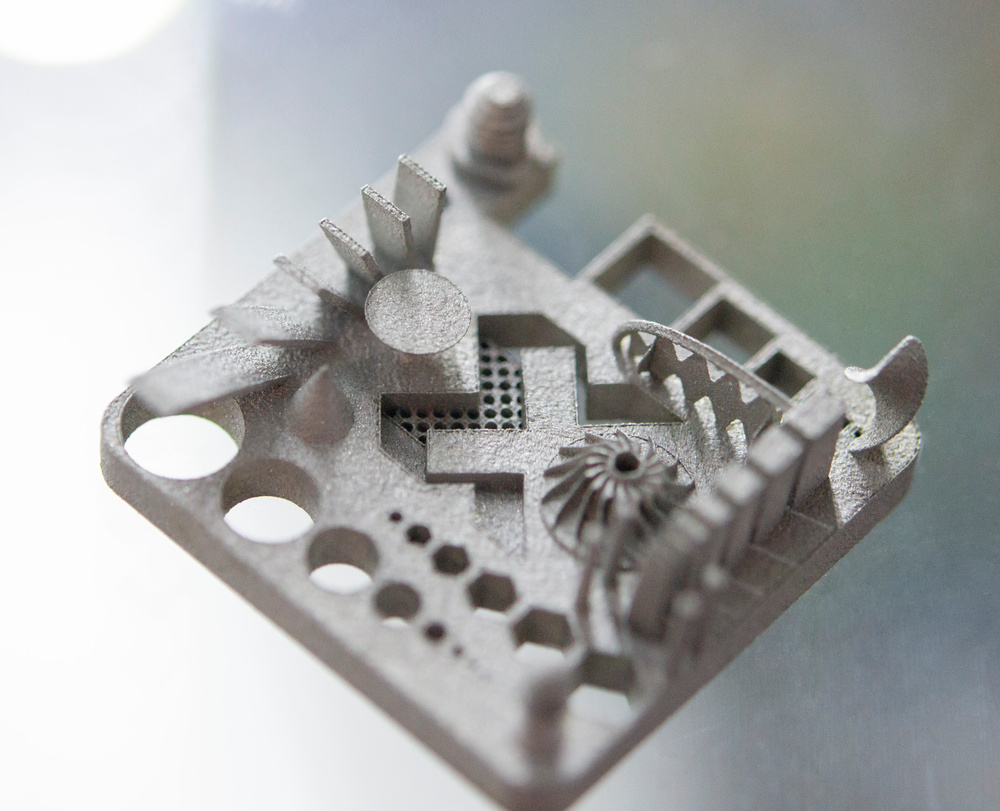

——Redefining Production Boundaries with Digital Capabilities, Establishing a Zero-Defect Manufacturing Paradigm

Core Technologies: Four Competitive Engines of CNC Machine Shops

- ±0.002mm Precision System, Setting Industrial Quality Standards

Utilizing five-axis machining centers paired with Renishaw laser tool setters, we achieve micron-level accuracy for complex components like aerospace gearboxes and optical instrument brackets. A semiconductor equipment manufacturer using this solution improved wafer transfer robotic arm positioning to 0.003mm, achieving a product yield rate of 99.6%. - 200+ Material Processing Matrix for Full-Scenario Applications

From aluminum alloy lightweight structures to high-temperature corrosion-resistant components, our dedicated tool library and cutting parameter database enable rapid transitions between titanium alloys, PEEK, ceramic matrix composites, and other specialty materials. A medical device client extended the fatigue life of cobalt-chromium orthopedic implants to 3x traditional methods through our production line. - “Digital Twin” System for Smart Factories

Our IoT-based shop floor management system monitors 68 equipment parameters in real-time, with AI algorithms predicting tool life errors ≤5%, ensuring batch production scrap rates remain below 0.12%. An automotive parts manufacturer boosted overall equipment effectiveness (OEE) by 27% after adopting this system. - Green Manufacturing Solutions

Integrated mist collectors and variable-frequency energy-saving systems reduce single-device energy consumption by 22%, with metal scrap recycling rates reaching 98%. We’ve completed carbon-neutral production line upgrades for 12 multinational corporations.

Industry Empowerment: Vertical Integration from Traditional to Strategic Emerging Sectors

| Sector | Typical Solutions | Technical Metrics | Client Value |

|---|---|---|---|

| EVs | Integrated die-cast molds/E-drive housings | 15m/min milling speed, Ra0.4μm surface finish | 40% longer mold life, 18% cost reduction |

| Biomedical | Surgical robot transmission components | 50μm micro-cavity machining, 100% sterile processing | FDA certification accelerated by 6 months |

| Consumer Electronics | Foldable screen hinges/AR glasses Mg alloy frames | 0.01mm assembly tolerance control | Drop-test pass rate increased to 99.3% |

| Energy Equipment | Wind turbine main shaft bearings/Nuclear reactor positioning parts | 8m-long workpiece straightness error ≤0.03mm/m | Equipment service life extended by 30% |

(Industry data: Enterprises adopting smart CNC shops average 35% higher productivity and 22% lower operational costs)

Service Ecosystem: Five Systems from Order Fulfillment to Technical Empowerment

1. Agile Development Support

- 48-hour rapid prototyping with industrial CT scanners for full-dimension reverse engineering

- CAE simulation & DFM analysis preemptively addressing 32 process risks

2. Flexible Production Capacity

- Modular lines handle 1-100,000pcs flexible orders with 60% faster changeover

- 20+ surface treatment options (anodizing, micro-arc oxidation, PVD coating)

3. Dual-Layer Quality Assurance

- Equipment: Heidenhain closed-loop encoders + tool compensation systems

- Inspection: CMM + AI visual inspection cloud platform

4. Global Delivery Network

- North America/Europe/SE Asia hubs with 72-hour emergency response

- Military-grade data encryption & NDAs, zero leaks in 5 years

5. Technology Co-Creation Program

- Joint digital twin lab with Tsinghua University, 14 patented innovations

- Free access to Smart Manufacturing Transformation Whitepaper

Why 328 Industry Leaders Choose Us

- Certification Portfolio: AS9100D Aviation/IATF 16949 Automotive/ISO 13485 Medical

- Cost Optimization: 23% material savings for a 3C client through cutting parameter optimization

- Delivery Speed: Emergency order response 2.7x faster than industry average

- Sustainability: EcoVadis Silver Certification holder for 3 consecutive years

Conclusion

At the intersection of smart manufacturing and mass customization, CNC machine shops are evolving from production executors to innovation incubators. With “Precision as Authority, Speed as Vitality” as our core philosophy, we deliver comprehensive intelligent manufacturing services across product lifecycles, empowering clients to lead industrial transformation.

Schedule a Free Production Line Audit to receive Smart Shop Upgrade Roadmap and 20% Off First Order – Let professional CNC capabilities become your competitive edge!

Technical parameters sourced from industry whitepapers and client testing data. Full case studies available on official website.