Our CNC machining capabilities

- Diameter & Length: We support customized processing according to customer-provided drawings or samples, covering both micro-sized parts (e.g., watch core components) and conventional industrial-sized parts. The specific processing range can be adjusted based on the complexity of the part and material characteristics, with no fixed restrictions on maximum/minimum dimensions (engineers will conduct feasibility assessments based on actual needs).

- Tolerance Precision: Relying on high-precision 5-axis processing equipment and advanced CNC programming technology, our CNC turning parts can achieve a tolerance of ±0.005mm, far exceeding the industry’s conventional precision standards, and fully meeting the precision requirements of high-end fields such as automotive, watch, and mechanical equipment.

- Surface Treatment: We provide integrated surface optimization solutions for turned parts, including mechanical polishing, chemical polishing, and electrochemical polishing (refer to our “CNC Metal Polishing Full Process Introduction” for details). The processed parts have a smooth surface (no burrs), uniform texture, and can be further customized with anti-corrosion, wear-resistant, or decorative surface treatments (e.g., plating, painting) according to customer needs.

Applicable Materials and Common Parts

1. Applicable Materials

- Metals: Stainless steel, aluminum alloy, brass, titanium alloy (all materials have been verified for processing performance, ensuring stable turning efficiency and part quality).

- Non-metals: Engineering plastics (e.g., ABS, POM) and rubber materials (suitable for parts requiring wear resistance or elasticity, such as plastic suction cup hooks).

2. Common Parts

- Industrial Components: Precision brass ball cooling nozzles (OEM/ODM supported, widely used in industrial cooling systems).

- Automotive Parts: Aluminum alloy transmission system parts, metal connecting parts (customized to match automotive assembly requirements, in line with automotive industry quality standards).

- Watch Parts: Stainless steel watch core components (tolerance can be further upgraded to ±0.003mm for high-end watch brands).

- Mechanical Equipment Parts: Gear shafts, bearing sleeves, and other transmission parts (adapt to various working conditions of mechanical equipment, with high strength and stability).

- Micro Parts: Miniature plastic/metal connectors for electronic equipment (small size, high precision, and stable performance).

Our processing procedures

1. Process Details

- Upload Drawings/Samples: Customers can send 2D/3D drawings (common formats such as CAD, PDF) or physical samples to our official email or online service platform. Our engineers will confirm the part structure, material requirements, and processing difficulty within 24 hours.

- Professional Quotation: Based on the drawing/sample evaluation results, we provide a transparent quotation plan, including material costs, processing fees, surface treatment fees, and delivery cycle. There are no hidden costs, and we can adjust the plan according to the customer’s budget or batch requirements.

- Precision Production: After the customer confirms the quotation and signs the contract, we start formal production. The entire production process is monitored in real time (including parameter debugging of CNC lathes, material cutting, and semi-finished product inspection) to ensure that the processing process is consistent with the drawing standards.

- Strict QC Inspection: We implement a “three-level quality inspection system” in accordance with ISO 9001:2000 quality management system standards:

- Pre-production: Review drawings and test material performance;

- In-production: Randomly inspect semi-finished products to avoid batch defects;

- Post-production: 100% full inspection of finished products (using precision measuring instruments to verify tolerance and surface quality), and only deliver products with a pass rate of 99.8% or higher.

2. Call to Action (CTA)

- Consultation Hotline: +86-18150097490

- Official Email: charlie@plasticmetalparts.com

We will provide you with a free feasibility assessment and quotation within 1 working day, and support urgent orders (sample delivery in 3-7 days) to help you speed up the project progress!

Typical Industry Cases

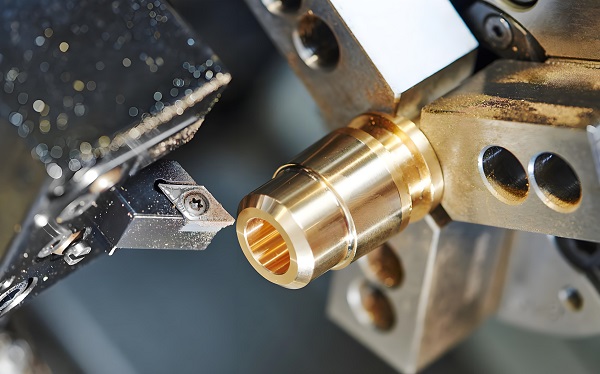

Case 1: Precision Brass Ball Cooling Nozzle (Industrial Cooling Field)

- Project Background: A cooperative customer (industrial equipment manufacturer) needed a high-precision cooling nozzle for their new generation of laser cutting machines, requiring corrosion resistance, smooth water flow, and a tolerance of ≤±0.01mm.

- Implementation Details:

- Material: High-purity brass (selected for good thermal conductivity and corrosion resistance);

- Processing: CNC turning + precision polishing;

- Key Indicators: Tolerance ±0.005mm, surface roughness Ra 0.8μm.

- Results: Batch delivery of 10,000+ pieces, zero quality complaints during customer use, and the product was rated “5/5” in customer satisfaction feedback (consistent with our official 5/5 service rating).

- Picture Description: Figure 1: Left – Finished precision brass ball cooling nozzle (showing smooth surface and spherical structure); Right – Corresponding processing drawing (marking tolerance and size parameters).

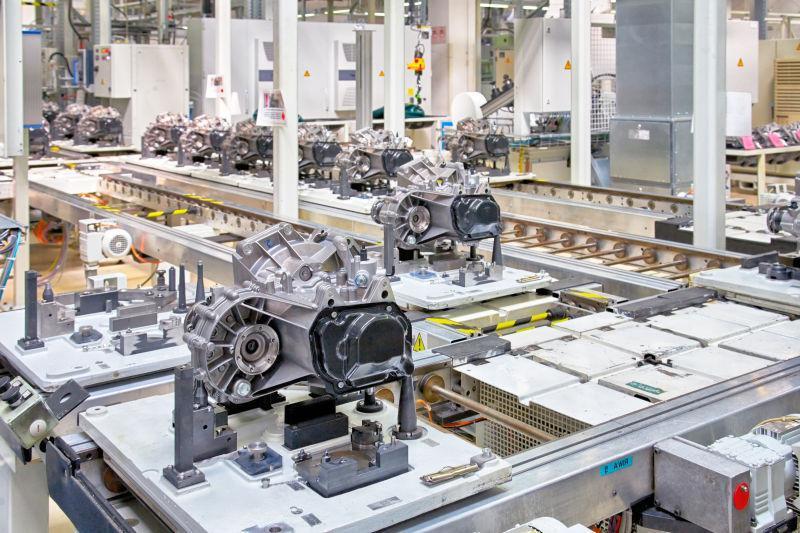

Case 2: Automotive Aluminum Alloy Transmission Part (Automotive Field)

- Project Background: A well-known automotive parts supplier commissioned us to produce aluminum alloy transmission shaft parts, requiring compliance with automotive industry durability standards and a delivery cycle of 15 days for 50,000 pieces.

- Implementation Details:

- Material: 6061 aluminum alloy (lightweight, high strength);

- Processing: High-speed CNC turning + anodizing (anti-corrosion treatment);

- Quality Certification: Passed SGS and CE product compliance testing.

- Results: The parts met the automotive industry’s torque and wear resistance requirements, with a batch pass rate of 99.9%. The delivery was completed 2 days in advance, and the customer renewed the annual cooperation agreement (annual order volume exceeds 50,000 pieces).

- Picture Description: Figure 2: Top – CNC turning production line for automotive aluminum alloy parts (showing automated processing); Bottom – Finished parts assembled into the automotive transmission system (demonstrating practical application effects).

Case 3: Watch Stainless Steel Core Part (Watch Field)

- Project Background: A high-end watch brand needed customized stainless steel core gears, requiring ultra-high precision (tolerance ≤±0.003mm) and a mirror-like surface.

- Implementation Details:

- Material: 316L stainless steel (anti-rust, high hardness);

- Processing: Micro-CNC turning + multi-stage electrochemical polishing;

- Inspection: Used a precision measuring microscope to verify dimensions.

- Results: The parts achieved a tolerance of ±0.002mm, with a surface finish reaching the mirror level (Ra 0.02μm), fully meeting the brand’s high-end positioning. The customer has maintained a quarterly cooperative batch of 2,000+ pieces.

- Picture Description: Figure 3: Close-up of the watch stainless steel core part (showing mirror surface and fine gear structure); Inset – Precision measuring microscope test scene.

- What materials can your CNC Turning service process? Are there any material restrictions?

Our CNC Turning service supports a variety of mainstream metal and non – metal materials, with no special material restrictions. The core applicable materials include:

Metals: Stainless steel, aluminum alloy, brass, titanium alloy, etc. (All have been verified for processing performance to ensure cutting stability and part quality);

Non – metals: Engineering plastics (such as ABS, POM), rubber, etc. (Suitable for parts that require wear resistance or elasticity, such as customized plastic suction cup hooks).

If you have special material requirements (such as high – temperature alloys), you can provide the material parameters, and our engineers will conduct a feasibility assessment and develop a customized processing plan.

- What accuracy can CNC Turning parts achieve? How to ensure stable accuracy?

Relying on high – precision equipment and strict quality control, the tolerance of our CNC Turning parts can be stably achieved at ±0.005mm; for high – precision demand scenarios such as core watch parts, the accuracy can be further optimized to ±0.003mm.

The specific accuracy guarantee measures are as follows:

Equipment level: Equipped with more than 100 high – precision processing equipment such as 5 – axis machining equipment, and regularly calibrate the equipment parameters to ensure accurate processing benchmarks;

Process level: Implement the “three – inspection system” under the ISO 9001:2000 quality management system – pre – production drawing review, in – production semi – finished product spot – check, and 100% full – inspection of finished products after production;

Personnel level: The processing path is programmed by CNC programmers with more than 10 years of experience to reduce human operation errors.

- What information is needed to customize CNC Turning parts? Can we cooperate without a complete drawing?

The core information required to customize CNC Turning parts is 2D/3D drawings, supporting mainstream formats such as CAD, PDF, STP, and SolidWorks. The drawings should clearly mark the part dimensions, tolerances, materials, and surface treatment requirements.

If you don’t have a complete drawing yet, cooperation is still possible if you only provide a physical sample: We can use 3D scanning equipment for reverse engineering, restore the sample structure and generate digital drawings. After you confirm the details, we will start the processing to ensure that the parts fully meet your requirements.

- Do your CNC Turning parts meet international standards? What relevant certifications do you have?

Our CNC Turning parts fully meet international quality and safety standards and have passed a number of authoritative certifications, specifically including:

ISO 9001:2000 Quality Management System Certification (covering the entire processing process to ensure compliance at each step);

SGS, CE product compliance certifications (applicable to export – oriented parts, meeting the market access requirements of Europe and the United States);

RoHS environmental protection certification (for electronic parts, ensuring that the materials are free of harmful substances).

For parts in special industries such as automotive and medical, we can also provide industry – specific test reports (such as wear – resistance and torque test reports for automotive parts).

- If there are quality problems with CNC Turning parts, how will it be handled? Is there after – sales support?

We provide a 12 – month after – sales guarantee for all CNC Turning parts, and the quality problem handling process is transparent and efficient:

Problem feedback: If there are processing – related quality problems such as out – of – tolerance or surface defects in the parts, you can provide problem photos and test data within 30 days after receiving the goods;

Solution: After confirming that it is our responsibility, we will provide free rework or replacement services and bear the round – trip logistics costs;

Long – term support: For batch – cooperation customers, we will regularly follow up on the use of parts and actively optimize the processing plan to avoid the recurrence of similar problems.

So far, the after – sales complaint rate of our CNC Turning parts is less than 0.2%, and the customer satisfaction remains at a full score of 5/5.

- What is the delivery cycle of CNC Turning parts? Do you support urgent orders?

The delivery cycle is flexibly adjusted according to the part complexity, material, and order quantity, as follows:

Sample orders (1 – 100 pieces): Usually delivered in 3 – 7 days;

Batch orders (100 – 10000 pieces): Delivered in 10 – 15 days;

Large – batch orders (more than 10000 pieces): Negotiated according to the production schedule, and can be delivered in batches.