Market Trends and Technical Advantages

Material Selection Guide

Material Performance Comparison Table

|

Material Type

|

Material Name

|

Accuracy

|

Tensile Strength (MPa)

|

Heat Resistance (℃)

|

Main Applications

|

|

Plastic

|

PLA

|

±0.1mm

|

50-60

|

50-60

|

Prototyping, education models

|

|

Plastic

|

ABS

|

±0.15mm

|

40-50

|

80-100

|

Automotive parts, appliance housings

|

|

Plastic

|

PETG

|

±0.12mm

|

55-65

|

70-80

|

Transparent parts, food containers

|

|

Metal

|

Stainless Steel

|

±0.05mm

|

500-600

|

800-1000

|

Mechanical parts, medical devices

|

|

Metal

|

Aluminum Alloy

|

±0.08mm

|

300-400

|

200-300

|

Aerospace parts, lightweight components

|

|

Metal

|

Titanium Alloy

|

±0.03mm

|

900-1100

|

400-600

|

Medical implants, engine parts

|

|

Resin

|

Standard Resin

|

±0.02mm

|

30-50

|

40-60

|

Jewelry, precision models

|

|

Resin

|

High-Temp Resin

|

±0.03mm

|

40-70

|

150-200

|

Automotive parts, electronic components

|

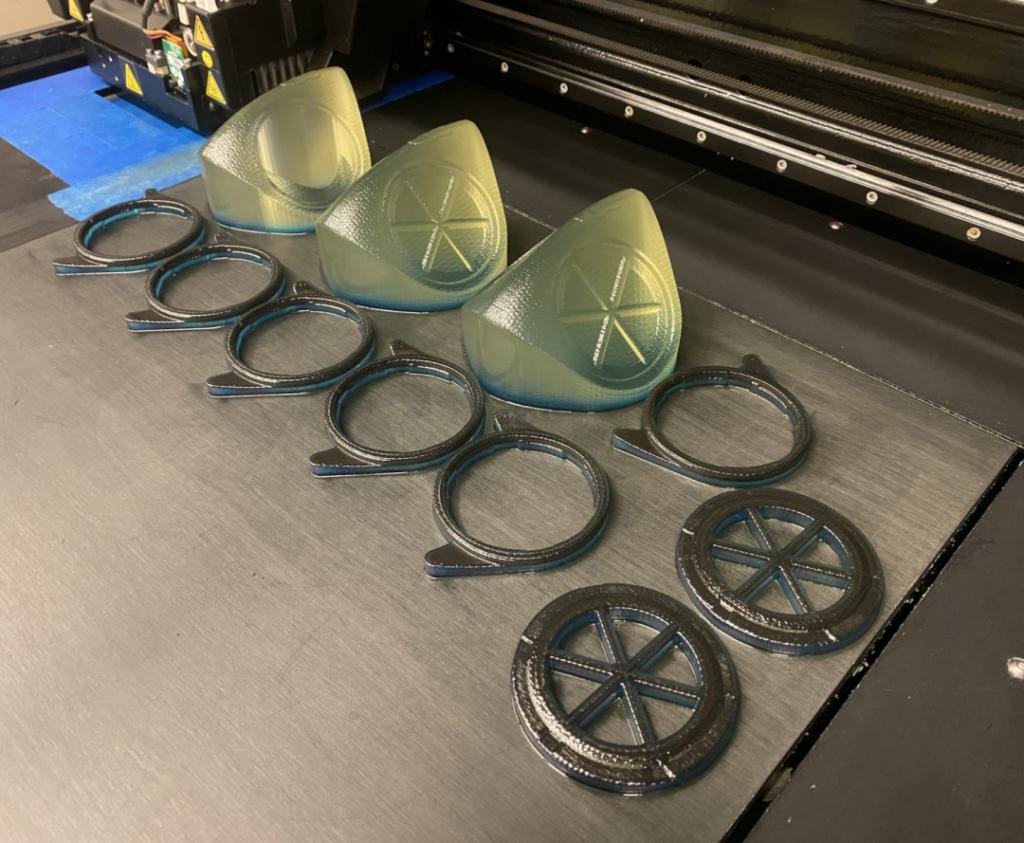

Plastic Materials

- Features: Biodegradable, environmentally friendly, easy to print

- Accuracy: ±0.1mm

- Applications: Prototyping, educational models, daily necessities

- Advantages: Odor-free printing process, good surface finish

- Features: High strength, good toughness, heat resistant

- Accuracy: ±0.15mm

- Applications: Automotive parts, appliance housings, functional prototypes

- Advantages: Excellent mechanical properties, suitable for functional testing

- Features: High transparency, strong impact resistance

- Accuracy: ±0.12mm

- Applications: Transparent parts, food-grade containers, medical device housings

- Advantages: Balances strength and aesthetics, good chemical stability

Metal Materials

- Features: High strength, corrosion resistant, good surface quality

- Accuracy: ±0.05mm

- Applications: Mechanical parts, medical devices, decorative parts

- Advantages: Suitable for complex structures, long service life

- Features: Lightweight, good thermal conductivity

- Accuracy: ±0.08mm

- Applications: Aerospace parts, automotive lightweight components

- Advantages: Light weight, high strength, relatively low cost

- Features: Good biocompatibility, extremely high strength

- Accuracy: ±0.03mm

- Applications: Medical implants, aircraft engine components

- Advantages: Excellent biocompatibility, suitable for human implantation

Resin Materials

- Features: High detail, smooth surface

- Accuracy: ±0.02mm

- Applications: Jewelry design, precision models, dental models

- Advantages: Strong detail expression, suitable for complex textures

- Features: Heat resistant, high mechanical strength

- Accuracy: ±0.03mm

- Applications: Automotive parts, electronic components, industrial molds

- Advantages: Can withstand 150-200℃ high temperature environment

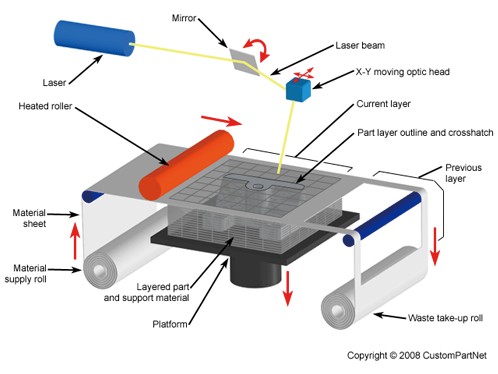

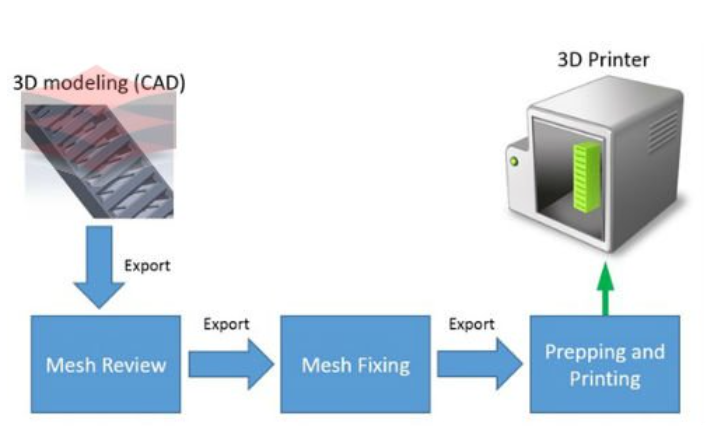

Technical Process Introduction

Service Process Timeline

|

Process Stage

|

Description

|

Time Required

|

Quality Control Points

|

|

Demand Analysis

|

Model evaluation, material selection

|

24 hours

|

Structural feasibility assessment

|

|

Model Optimization

|

Topology optimization, slicing

|

4-8 hours

|

Support structure optimization

|

|

Printing Manufacturing

|

Precision printing process

|

1-7 days

|

Real-time process monitoring

|

|

Post-processing

|

Support removal, surface treatment

|

2-48 hours

|

Dimensional accuracy inspection

|

|

Quality Inspection

|

Precision measurement, performance testing

|

4-24 hours

|

3D coordinate measurement

|

|

Packaging Delivery

|

Professional packaging, logistics arrangement

|

1-3 days

|

Transportation safety guarantee

|

Standard Service Process

- Professional engineers conduct structural analysis of 3D models

- Provide material selection and process recommendations

- Evaluate printing feasibility and cost budget

- Time: Evaluation completed within 24 hours

- Topology optimization of models to reduce support structures

- Intelligent slicing software automatically generates printing paths

- Preview printing effects to ensure quality

- Time: 4-8 hours

- Select appropriate equipment based on materials and processes

- Real-time monitoring of printing process to ensure stability

- Multi-layer quality inspection to ensure precision requirements

- Time: 1-7 days depending on part size and complexity

- Remove support structures and fine polishing

- Surface treatment (spraying, dyeing, polishing, etc.)

- Precision inspection with 3D measuring instrument

- Time: 2-48 hours

- Professional packaging to prevent transportation damage

- Provide quality inspection reports

- On-time delivery and after-sales service tracking

- Time: 1-3 days

Quality Control System

- Incoming Material Inspection: All materials come from well-known suppliers, with quality sampling inspection for each batch

- Process Monitoring: Real-time monitoring of printing process, automatic recording of key parameters

- Finished Product Inspection: Precision inspection using coordinate measuring machine to ensure ±0.05mm tolerance requirements

- Quality Traceability: Establish complete production records, traceable to every link

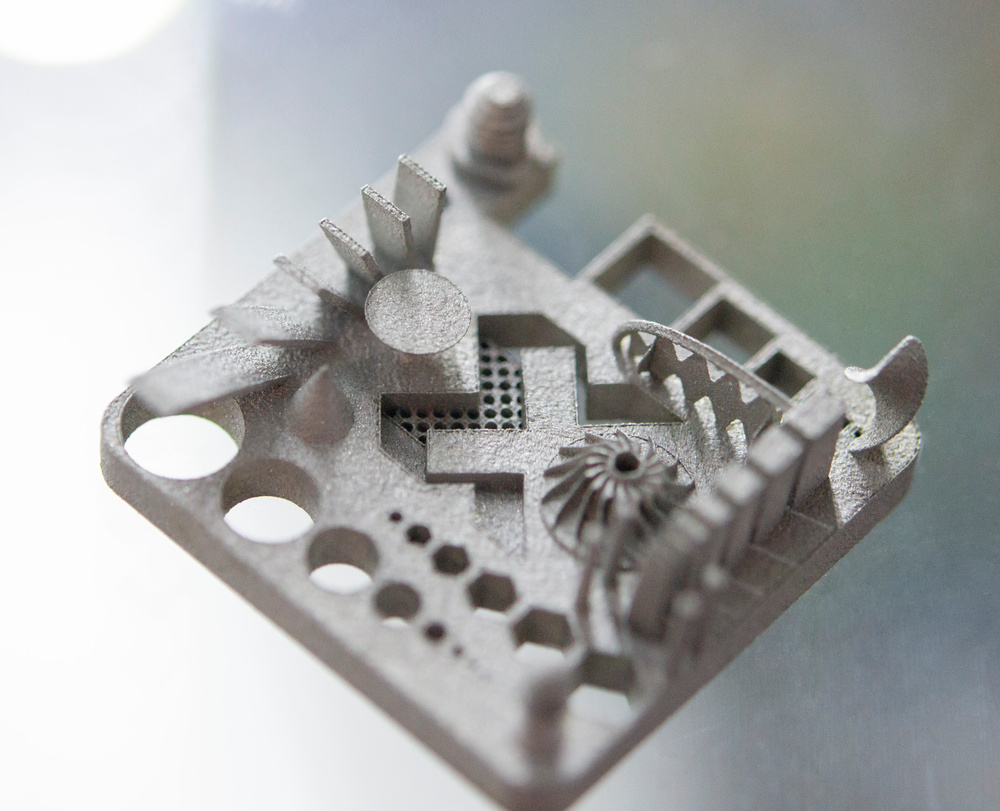

Technical Advantages Analysis

Precision and Efficiency

- Industrial-grade equipment printing error less than 0.1mm

- Metal 3D printing precision up to ±0.03mm

- Surface roughness Ra≤6.3μm, meeting most industrial application requirements

- Prototyping completed within 24-48 hours

- Small batch production delivery in 7-15 days

- 30%-50% shorter production cycle compared to traditional manufacturing methods

Design Freedom

- No need to consider traditional processing limitations

- Can manufacture complex structures such as internal cavities and hollow designs

- Integrated molding reduces assembly steps

- Topology optimization algorithm achieves 15%-30% weight reduction

- Reduce material consumption while maintaining strength

- Especially suitable for aerospace and automotive industries

Cost Advantages

|

Production Method

|

Initial Investment

|

Unit Cost (1-100pcs)

|

Unit Cost (100-1000pcs)

|

Lead Time

|

|

3D Printing

|

Low (no mold cost)

|

Medium

|

Low

|

Short (1-15 days)

|

|

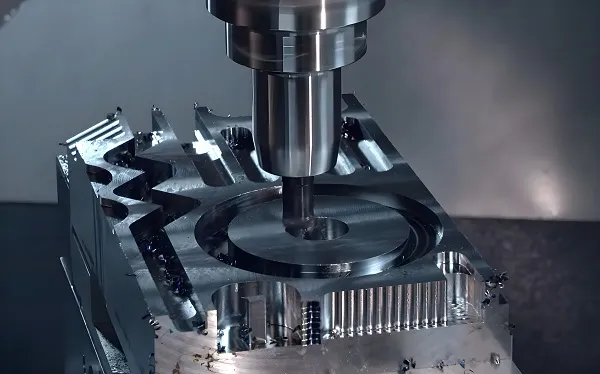

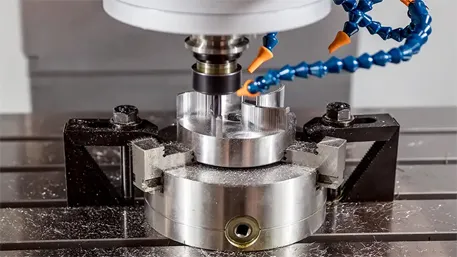

CNC Machining

|

Medium

|

High

|

Medium

|

Medium (5-20 days)

|

|

Injection Molding

|

High (mold cost)

|

Very Low

|

Very Low

|

Long (20-45 days)

|

- Additive manufacturing reduces material waste

- Material utilization rate over 90%, much higher than 60% of traditional processes

- Support multiple material recycling

- No mold opening required, reducing upfront investment

- Suitable for small batch customization of 1-1000 pieces

- Unit cost does not increase significantly with decreasing batch size

Application Field Display

Industry Application Statistics

|

Industry

|

Market Share

|

Typical Applications

|

Growth Rate

|

|

Automotive

|

34.5%

|

Engine parts, lightweight components

|

25%

|

|

Aerospace

|

18.2%

|

Structural parts, engine components

|

32%

|

|

Medical

|

22.8%

|

Implants, surgical guides, dental

|

40%

|

|

Consumer Electronics

|

15.3%

|

Prototypes, customized parts

|

18%

|

|

Others

|

9.2%

|

Education, art, research

|

28%

|

Automotive Manufacturing

- Material: ABS + carbon fiber reinforcement

- Accuracy: ±0.1mm

- Quantity: 50 pieces

- Delivery Time: 7 days

- Cost Saving: 40% cost reduction compared to traditional CNC machining

- Engine component prototype verification

- Interior component functional testing

- Aerodynamic models

- Customized tools and fixtures

Medical Healthcare

- Material: Titanium alloy TC4

- Accuracy: ±0.03mm

- Features: Patient-specific design, perfect matching of bone structure

- Postoperative Effect: 30% shorter recovery period, 70% lower infection rate

- Personalized orthopedic implants

- Surgical guides and planning models

- Dental restorations

- Medical device housings

Aerospace

- Material: Aluminum alloy AlSi10Mg

- Accuracy: ±0.05mm

- Advantages: 35% weight reduction, strength maintained

- Performance Improvement: 20% longer flight time

- Lightweight structural parts

- Complex internal cavity components

- Rapid prototype verification

- Small batch spare parts production

Consumer Electronics

- Material: PETG transparent material

- Accuracy: ±0.1mm

- Features: High transparency, good impact resistance

- Delivery Time: 48 hours

- Product appearance prototypes

- Functional button test pieces

- Customized housings

- Precision mold making

Service Commitment

Quality Assurance

- All parts meet the precision requirements agreed in the contract

- Provide detailed inspection reports and data

- Free rework or refund for products that do not meet requirements

- Use high-quality materials that meet international standards

- Provide material certification and quality assurance

- Ensure mechanical properties and chemical stability of products

Delivery Guarantee

- Complete demand assessment and quotation within 24 hours

- Prototype production delivered within 48 hours

- Small batch production delivered in 7-15 days

- 24-hour emergency service for urgent orders

- Professional packaging to ensure transportation safety

- Cooperation with well-known logistics companies for full tracking

- 2-3 days delivery nationwide

Technical Support

- Engineering team with over 10 years of experience

- Familiar with multiple 3D printing processes and material characteristics

- Provide professional design optimization suggestions

- Provide 3D printing technology training for customers

- Share best practices and design guidelines

- Regular technical exchange activities

Quick Quote

- 3D Model File: Support STL, STEP, OBJ and other formats

- Material Requirements: Plastic, metal, resin, etc.

- Precision Requirements: Tolerance range and surface quality requirements

- Quantity Requirements: Printing quantity and delivery time requirements

- Special Requirements: Post-processing, surface treatment, etc.

Service Process