Why Choose XM Gold Cattle for Your CNC Machining Needs?

With 26 years of manufacturing excellence, XM Goldcattle stands as a leading provider of precision CNC machining services. As a national high-tech enterprise, we specialize in delivering customized solutions for industries ranging from aerospace to medical devices. Our state-of-the-art facilities and experienced engineering team ensure that every project meets the most stringent quality standards.

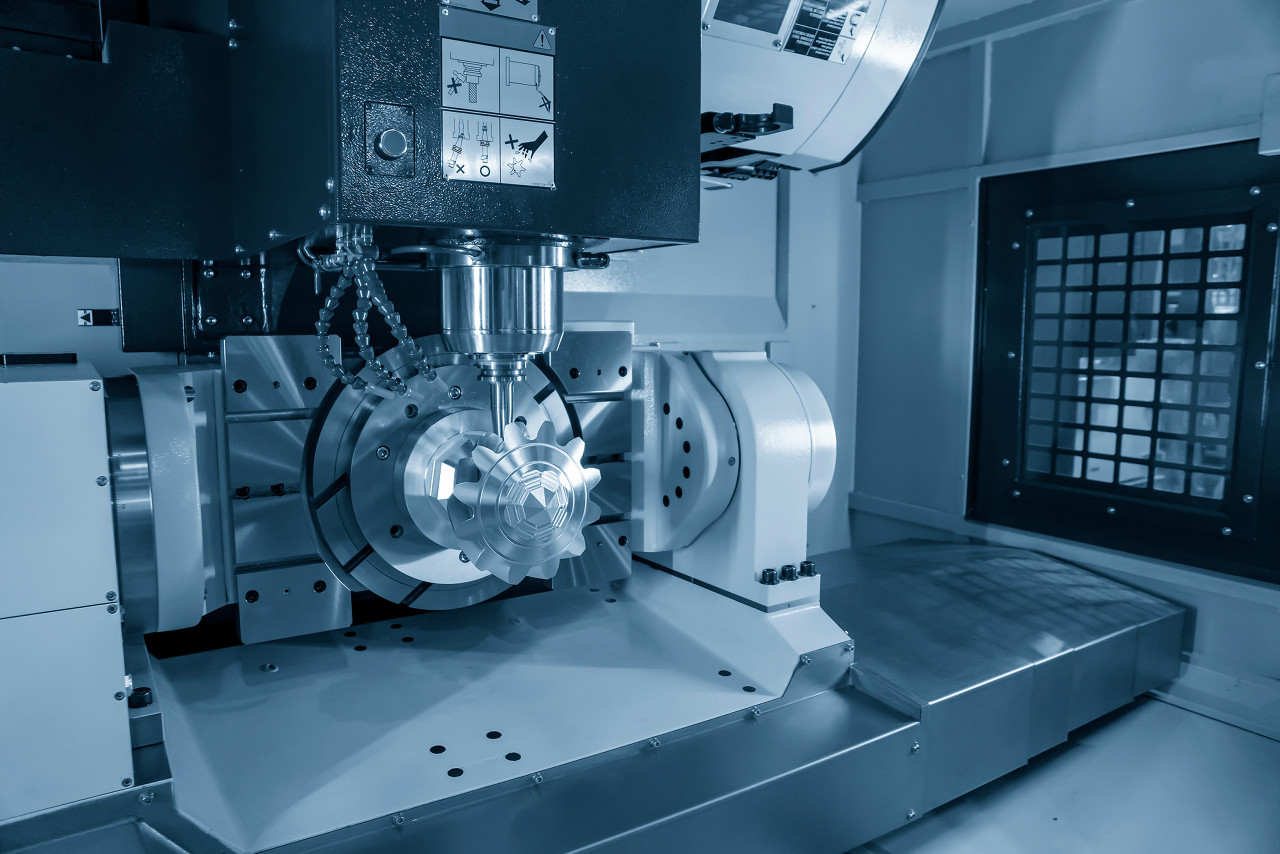

Our modern CNC machining facility equipped with advanced precision equipment

Our Core CNC Machining Capabilities

1. Ultra-Precision 5-Axis CNC Machining

Accuracy You Can Trust:

- Standard Tolerance: ±0.01mm for general components

- High Precision: ±0.005mm for critical applications

- Ultra-High Precision: ±0.002mm for specialized aerospace and medical parts

5-axis CNC machining center cutting complex mechanical parts with solid ball end-mill tools

Advanced Equipment:

- 2 Mazak 5-axis CNC machining centers

- Wire EDM machines for complex geometries

2. Comprehensive Material Expertise

We excel in machining a wide range of materials to meet your specific requirements:

Metals

- Aluminum Alloys: 6061-T6, 7075, 2024 (aerospace grade)

- Stainless Steel: 304, 316, 17-4 PH (medical grade)

- Titanium: Ti-6Al-4V (biocompatible for medical implants)

- Brass & Copper: C36000, C11000 (electrical components)

Plastics

- Engineering Plastics: PEEK, Delrin, Nylon, POM

- High-Temperature Plastics: PTFE, PEI, PPS

- Transparent Materials: Acrylic, Polycarbonate

Specialty Materials

- Magnesium Alloys (lightweight applications)

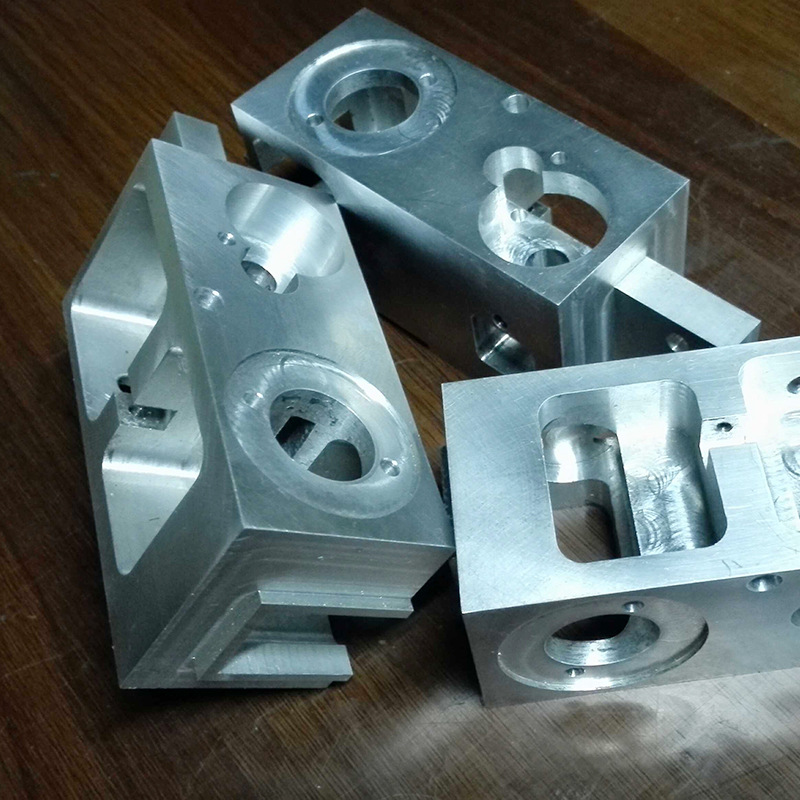

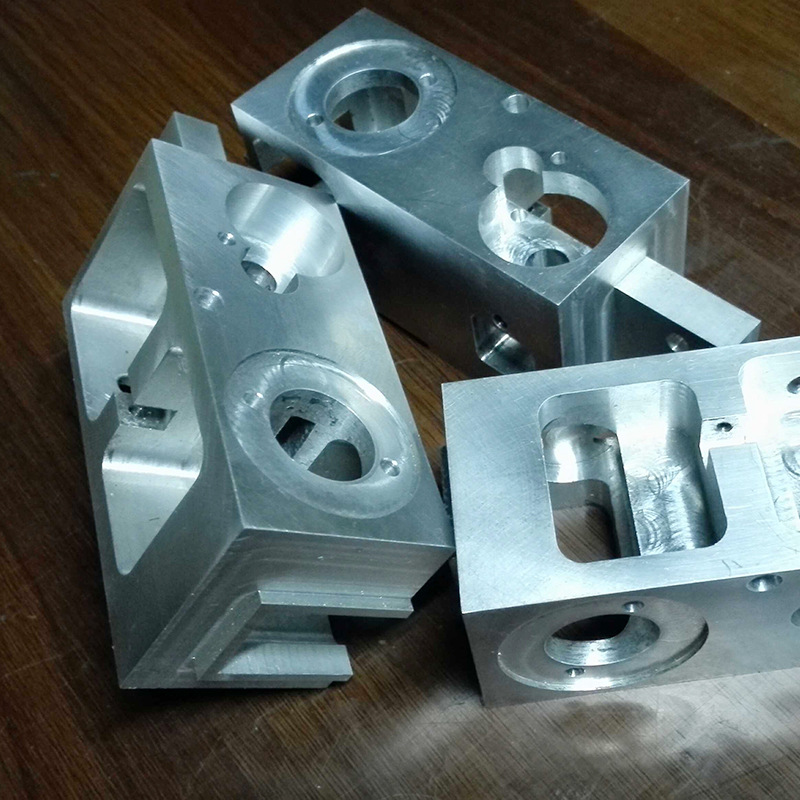

Precision CNC machined aluminum components showcasing our high-quality surface finish

3. Surface Finishing Excellence

Our comprehensive surface treatment capabilities ensure your parts meet both functional and aesthetic requirements:

- Mechanical Finishes: Polishing, Sandblasting, Brushing

- Chemical Treatments: Anodizing, Passivation, Black Oxide

- Plating Services: Nickel, Chrome, Zinc Plating

- Coatings: Powder Coating, Electrophoresis

- Medical-Grade Finishes: Ra 0.1μm mirror polish

Industry-Specific Solutions

Aerospace & Defense

- AS9100 Certified Processes

- Titanium and Inconel component machining

- Complex structural parts with tight tolerances

- Flow-down compliance documentation

High-precision aerospace components manufactured to exacting military specifications

Medical Devices

- Biocompatible material processing

- Surgical instrument components

- Implantable device manufacturing

- Cleanroom production environment

Medical device components with biocompatible finishes and precise tolerances

Automotive & Transportation

- Lightweight aluminum components

- Engine parts and transmission components

- Electric vehicle battery housings

Electronics & Telecommunications

- 5G communication enclosures

- Heat sinks and thermal management parts

- Precision gears and mechanisms

Our Manufacturing Process Excellence

1. Design for Manufacturability (DFM) Analysis

Our engineering team provides expert DFM advice to optimize your designs for:

- Material selection guidance

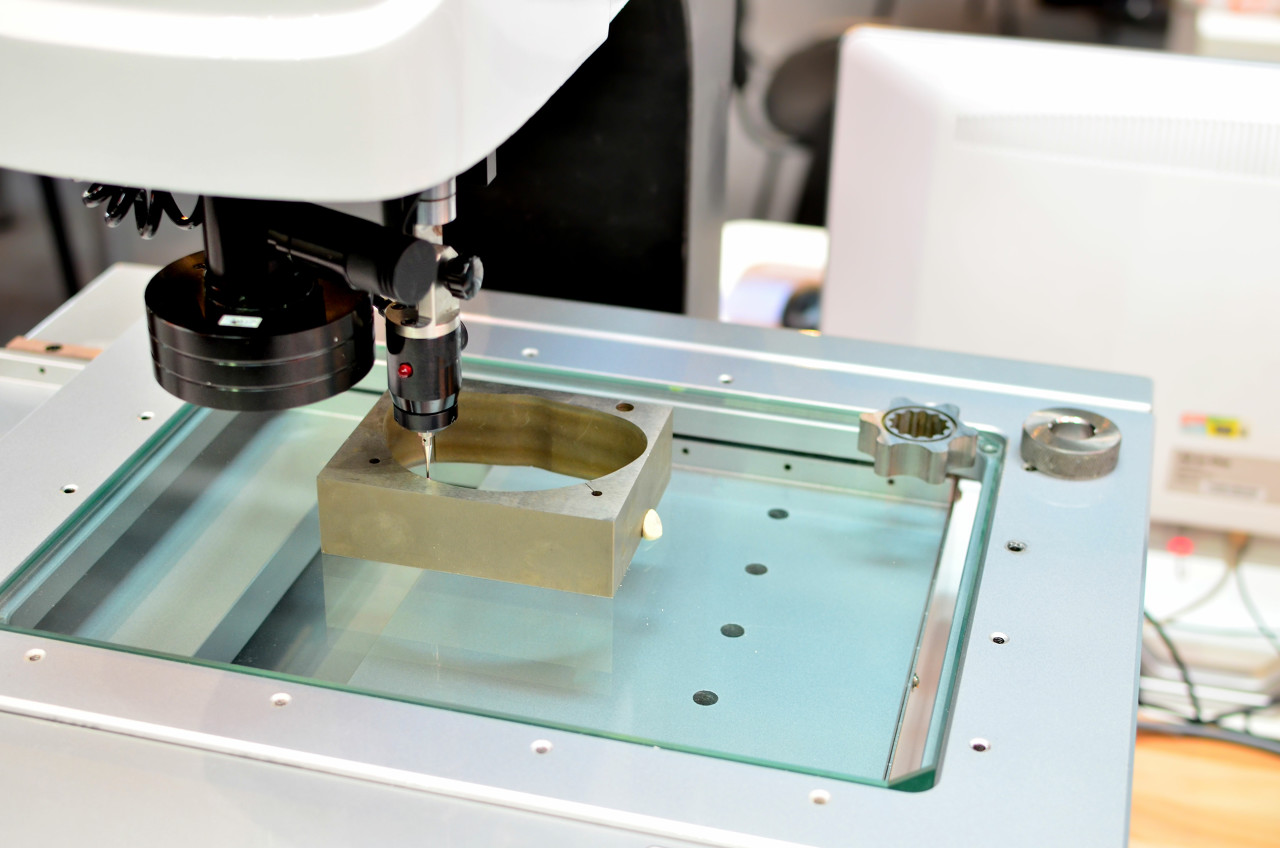

2. Quality Control System

- 100% Inspection Before Shipment

- CMM (Coordinate Measuring Machine) for dimensional verification

- Optical projectors and precision gauges

- Material certification and traceability

- Statistical Process Control (SPC)

CNC touch probes for quality control and precision measurement on milling machines

3. Rapid Prototyping to Mass Production

- No MOQ Requirement: Start with 1 piece prototypes

- Fast Turnaround: 1-7 days for sample production

- Scalable Production: Up to 1,000,000 pieces per month

- Consistent Quality: Same precision from prototype to production

Why XM Goldcattle Stands Out

Technical Advantages

- 26 Years of Manufacturing Experience

- National High-Tech Enterprise Certification

- ISO 9001 Quality Management System

- Advanced 5-axis machining capabilities

- In-house tooling and mold making

Service Commitment

- 2-Hour Response Time for inquiries

- 96.4% On-Time Delivery Rate

- Customized Solutions for unique requirements

- Global Supply Chain Management

- Dedicated Account Managers for each project

Competitive Edge

- Cost-Effective Pricing without compromising quality

- Continuous Process Improvement

- Sustainable Manufacturing Practices

- Investment in New Technologies

- Skilled Workforce with Average 8+ Years Experience

Our Manufacturing Facility

Location: Xiamen, Fujian Province, China

Facility Size: 5,000 square meters

Workforce: 600+ skilled employees

Production Capacity: 1 million pieces monthly

Export Markets: USA, Europe, Japan, Southeast Asia

Get Your Precision CNC Machining Quote Today

Whether you need a single prototype or high-volume production, XM Goldcattle has the expertise and capabilities to deliver exceptional results. Our team of engineers is ready to assist with your next project.

Contact Us Now:

- Email: charlie@plasticmetalparts.com

- WhatsApp: +86-18150097490

We look forward to becoming your trusted manufacturing partner!

Certifications: ISO 9001 | ISO 13485 | IATF 16949 | National High-Tech Enterprise

Year Established: 1999

Main Markets: North America , Europe , Asia ,