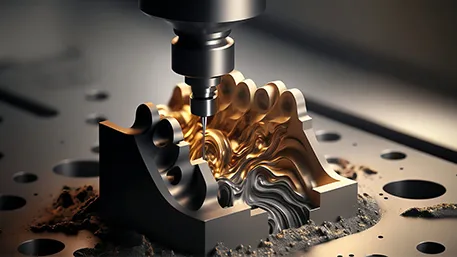

Precision Redefined: Core Technical Parameters

1. Micro-Tolerance Mastery

Our ISO 13485-certified system achieves dimensional control surpassing industrial benchmarks:

| Feature | Standard Industry | Xiamen Goldcattle Performance |

|---|---|---|

| Critical Dimensions | ±0.05mm | ±0.015mm |

| Surface Finish | Ra 0.4μm | Ra 0.12μm |

| Insert Positioning | ±0.1mm | ±0.03mm |

Validated through 12,000-cycle testing on Fanuc ROBOSHOT α-S100iB presses

2. Material-Specific Tooling Architecture

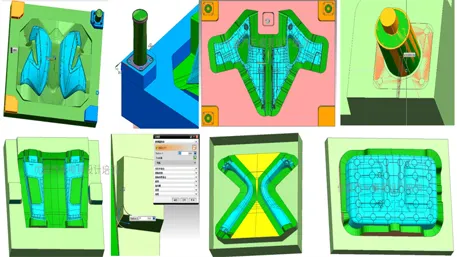

Our proprietary mold design logic adapts to material physics:

For Engineering Plastics (e.g., PEEK, PEI):

- 3-stage progressive cooling channels

- Titanium alloy inserts (HRC 42-45)

- 0.02mm venting clearance optimization

For Flexible Compounds (TPU, TPE):

- Negative draft angle compensation (0.25°-1.5°)

- Electropolished cavities (Mirror Class A2)

- Pneumatic ejection systems

Customization Engineered for Complexity

1. Multi-Material Integration Solutions

Breakthrough in hybrid molding for medical devices:

Component | Technology Stack | Cycle Time

Surgical Handle | Overmolding + Gas Assist | 38s

IV Connector | Micro-injection + LSR | 42s

Implant Trial | Metal Insert + PEEK | 55s

2. Rapid Conversion System

Modular components enable mold reconfiguration within 8 hours:

- DIN 16901-compliant base plates

- HSK 63F quick-change interfaces

- Pre-hardened tool steel inserts (1.2344 ESR)

Quality Assurance Matrix

1. In-Process Monitoring Pyramid

Tier 1: Cavity Pressure Sensors (100% cavities)

Tier 2: IR Thermal Imaging (0.1°C resolution)

Tier 3: 3D Laser Scanning (15μm accuracy)

Tier 4: CT Scanning (Critical Medical Parts)

2. Traceability Protocol

Blockchain-based material tracking from resin pellets to shipped components:

- Batch-specific crystallinity data

- Mold maintenance history visualization

- Real-time production floor monitoring

Strategic Advantages for Western Partners

1. Dual-Region Manufacturing Footprint

Xiamen Facility:

- 65 presses (50-3000T)

- Class 7 cleanroom

- AS9100 aerospace certification

European Tech Center (Stuttgart):

- Localized prototyping

- DFM consultation

- CE compliance testing

2. Technical Partnership Model

Phase 1: Co-development (6-8 weeks)

- Material compatibility analysis

- Moldflow simulation

- Design-for-Manufacturing workshop

Phase 2: Pilot Production (2-4 weeks)

- 500-5,000 trial parts

- Process validation documentation

Phase 3: Ramp-Up Protocol

- 24/7 remote monitoring

- Predictive maintenance scheduling

The Unspoken Edge: Xiamen’s Ecosystem

Leverage our unique position in China’s mold-making capital:

- 48-hour rapid tooling through local supplier network

- On-demand access to 15+ material certification labs

- Government-backed R&D incentives for long-term projects

In the intricate dance of precision molding, success lies not in chasing specs but in mastering the interplay between material behavior and mechanical constraints. Our engineers don’t just build molds – we craft molecular-level control systems disguised as tooling. The true measure of our work isn’t in the first article inspection report, but in the unspoken confidence when your quality team signs off on batch #1003 without hesitation. That’s the Xiamen Goldcattle benchmark – where precision becomes predictable, and predictability becomes profit.