In today’s precision manufacturing field, stainless steel parts have become the material of choice for high-end industries such as aerospace, medical devices, and automotive manufacturing due to their excellent corrosion resistance, high strength, and aesthetic surface finish. However, machining stainless steel is not an easy task. Its high hardness, low thermal conductivity, and work hardening characteristics place extremely high demands on manufacturing enterprises. Against this backdrop, Xiamen Goldcattle has developed into an industry benchmark in CNC stainless steel parts customization services with 26 years of professional experience.

Technical Strength: Core Competitiveness in Precision Machining

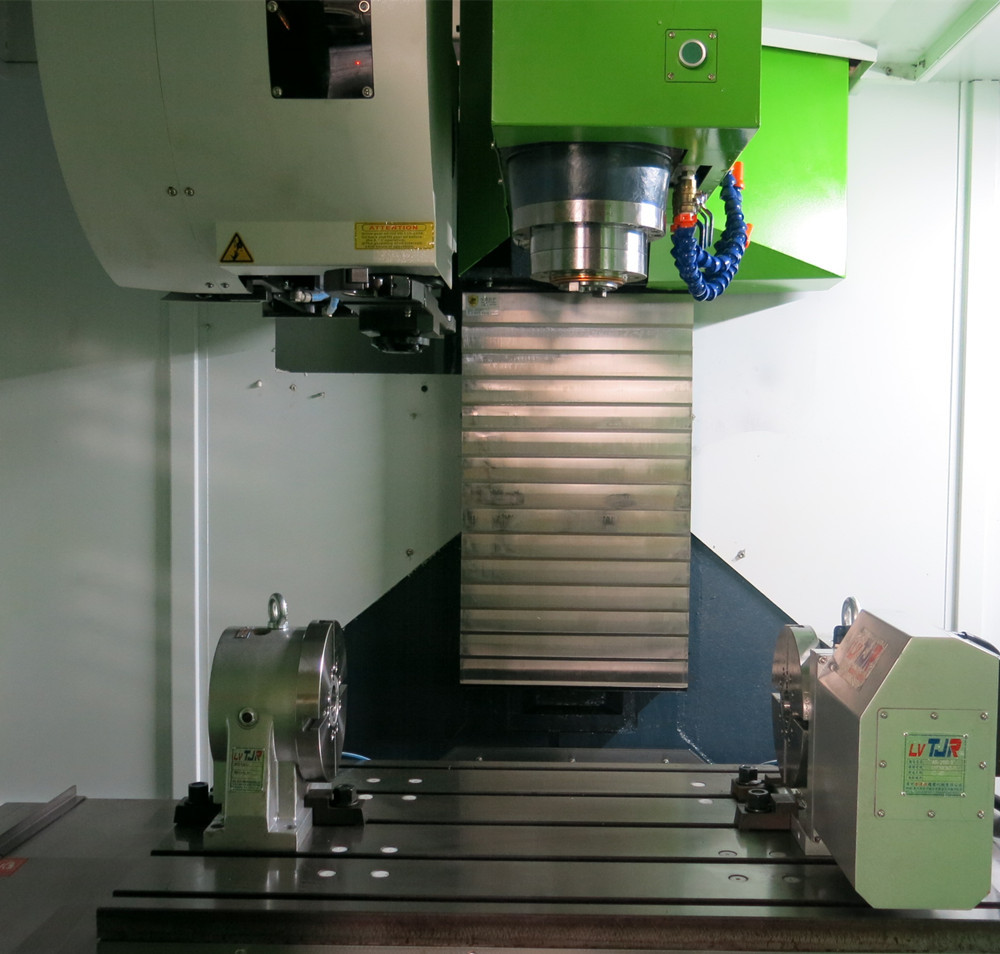

Walking into Xiamen Goldcattle’s modern production workshop, dozens of high-precision CNC machining centers are neatly arranged, emitting an orderly operational hum. As a national high-tech enterprise, Xiamen Goldcattle has accumulated profound technical expertise in the field of stainless steel precision machining.

Processing precision reaches industry-leading levels: The company’s CNC machining equipment can achieve processing precision of ±0.005mm, an indicator that has reached the manufacturing standards for aerospace components. Whether it’s complex geometric shapes or precision fitting dimensions, Xiamen Goldcattle can perfectly meet customer design requirements.

Professionalism in material handling: Xiamen Goldcattle is proficient in the machining characteristics of various stainless steel materials:

- 304 stainless steel: Although relatively easy to machine, it is prone to tool adhesion, requiring special tool angles and cutting parameters

- 316 stainless steel: More corrosion-resistant but with higher cutting resistance, requiring optimized tool coatings and cooling methods

- 17-4PH stainless steel: Precipitation-hardening steel with high hardness and severe work hardening, requiring layered cutting technology

For 316 stainless steel, a commonly used high-end material, Xiamen Goldcattle has developed specialized machining parameter standards:

- Material hardness controlled within 200-250HB range

- Cutting speed optimized to 150-300m/min

- Feed rate precisely set at 0.1-0.3mm/r

- Cutting depth controlled at 0.5-2.0mm

Customization Process: Full-Chain Service from Design to Delivery

Xiamen Goldcattle deeply understands that high-quality customization services are not just a reflection of processing capabilities, but a perfect coordination of the entire service process. The company has established a comprehensive 7-step customization process to ensure that every project is completed efficiently and with high quality.

1. Requirement consultation stage: Customers put forward specific requirements, including part drawings, material requirements, precision standards, and quantities. Xiamen Goldcattle’s engineering team will conduct in-depth analysis of these requirements and provide professional technical advice.

2. Technical evaluation and quotation: Based on customer requirements, the technical team conducts feasibility analysis, develops detailed processing plans, and provides transparent quotations. This stage is usually completed within 24-48 hours.

3. Sample confirmation: For first-time cooperation or complex parts, Xiamen Goldcattle will first produce samples for customer confirmation. The sample production cycle is generally 3-7 days, ensuring that customers can verify product quality before mass production.

4. Production preparation: After sample confirmation, the company begins preparing tools, fixtures, and process documents required for mass production to ensure smooth production processes.

5. Mass production: Advanced production management systems are adopted to monitor production progress and quality in real-time. The production cycle varies depending on part complexity and quantity, usually 7-15 days.

6. Quality inspection and delivery: Each batch of products undergoes strict quality inspection, including dimensional measurement and surface quality inspection. Qualified products are packaged and delivered according to customer requirements.

7. After-sales service: Xiamen Goldcattle provides comprehensive after-sales service, including technical support and quality issue resolution, to ensure long-term customer satisfaction.

Industry Applications: Covering Multiple High-End Manufacturing Fields

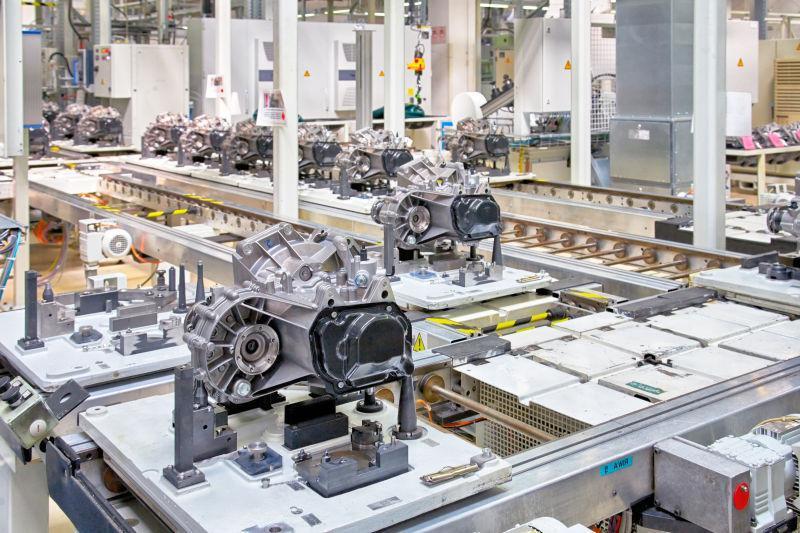

Xiamen Goldcattle’s CNC stainless steel parts customization services have been widely applied in multiple high-end manufacturing fields:

Medical device industry: Producing high-precision surgical instruments and medical equipment components, requiring surface roughness below Ra 0.8μm to ensure product biocompatibility and usage safety.

Aerospace field: Manufacturing aircraft engine components and spacecraft structural parts, which require extremely high dimensional accuracy and must withstand extreme temperature and pressure conditions.

Automotive manufacturing: Providing precision transmission system parts and exhaust system parts for high-end automotive brands, meeting the strict safety and reliability requirements of the automotive industry.

Electronic equipment: Producing precision connectors, heat sinks, and other electronic components that require good conductivity and heat dissipation performance.

Quality Control: Establishing a Comprehensive Quality Management System

Quality is the lifeline of Xiamen Goldcattle. The company has established a comprehensive quality management system with strict quality control measures at every stage from raw material procurement to finished product delivery.

Raw material control: All stainless steel materials come from well-known suppliers with complete material certificates. Materials undergo chemical composition analysis and mechanical property testing before entering the factory.

Process quality control: Statistical Process Control (SPC) methods are adopted to monitor key parameters in the machining process in real-time, promptly detecting and correcting deviations.

Precision testing equipment: Equipped with advanced testing equipment, including coordinate measuring machines, projectors, and surface roughness meters, ensuring product quality meets requirements.

Quality certifications: The company has obtained multiple international certifications including ISO9001 Quality Management System Certification and ISO13485 Medical Device Quality Management System Certification, demonstrating its professional capabilities in quality control.

Technological Innovation: Driving Force for Industry Development

In the fierce market competition, technological innovation is the key for Xiamen Goldcattle to maintain its leading position. The company invests 5% of its sales revenue in research and development annually, continuously improving processing technology and product quality.

Smart manufacturing technology: Introducing Industry 4.0 concepts and establishing intelligent production workshops. Achieving equipment interconnection through IoT technology, optimizing production parameters through big data analysis, and predicting maintenance needs through artificial intelligence.

New process development: Developing specialized machining processes for different materials and part types. For example, for thin-walled stainless steel parts, special fixture designs and machining path optimization technologies have been developed to effectively control machining deformation.

Tool technology innovation: Cooperating with tool manufacturers to develop specialized tools, optimizing tool materials and geometric parameters for stainless steel machining characteristics, improving machining efficiency and tool life.

Market Prospects: Seizing Industry Development Opportunities

As manufacturing moves towards high-end and intelligent development, market demand for CNC stainless steel parts customization services continues to grow. According to industry analysis reports, the global precision manufacturing market is expected to reach $500 billion by 2025, with a compound annual growth rate maintaining above 6%.

Technology trends:

- Processing precision requirements are getting higher, developing from micron level to nanometer level

- Material types are constantly enriched, with new stainless steel alloys being increasingly applied

- Manufacturing cycles are required to be shorter, posing higher challenges to production efficiency

Market opportunities:

- Continued development of high-end industries such as medical devices and aerospace

- Emergence of new fields such as new energy vehicles and 5G communications

- In-depth implementation of the “Made in China 2025” strategy

With its technical strength and service advantages, Xiamen Goldcattle is in a favorable position to seize these opportunities. The company plans to expand its production scale by 50% within the next three years, further enhancing its market share in the high-end manufacturing field.

Conclusion: Inheriting Craftsmanship, Creating the Future with Intelligence

Over 26 years of development, Xiamen Goldcattle has always adhered to the business philosophy of “high quality, high efficiency, integrity, and service”, establishing an industry benchmark in CNC stainless steel parts customization services. From its humble beginnings as a small workshop to today’s modern manufacturing enterprise, from single processing services to comprehensive customization solutions, every step of Xiamen Goldcattle’s development reflects its persistent pursuit of quality and continuous innovation in technology.

In the era of smart manufacturing, Xiamen Goldcattle will continue to uphold the spirit of craftsmanship, continuously improving technical levels and service quality, providing customers with more precise and efficient CNC stainless steel parts customization services. It is believed that in the near future, Xiamen Goldcattle will become a well-known brand in the global precision manufacturing field, contributing to the rise of Chinese manufacturing.

If you are looking for a professional CNC stainless steel parts customization service provider, Xiamen Goldcattle is undoubtedly your best choice. With 26 years of industry experience, advanced production equipment, a comprehensive quality system, and an excellent service team, Xiamen Goldcattle will provide you with one-stop solutions from design to delivery, helping your products stand out in the fierce market competition.

Contact Xiamen Goldcattle and start your precision manufacturing journey today!