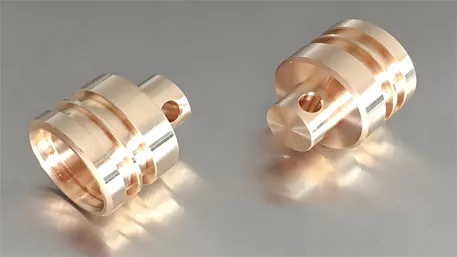

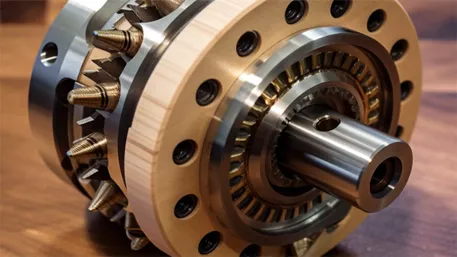

CNC titanium alloy parts represent the pinnacle of precision manufacturing, combining the exceptional properties of titanium with the accuracy of computer numerical control machining. These components are revolutionizing industries from aerospace to medical devices, offering unmatched strength-to-weight ratio, corrosion resistance, and biocompatibility.

What makes titanium special compared to other metals?

Titanium stands out due to its unique combination of properties:

- Exceptional strength-to-weight ratio: Stronger than steel but 40% lighter

- Superior corrosion resistance: Outperforms stainless steel in harsh environments

- Biocompatibility: Perfect for medical implants with no adverse reactions

- Temperature stability: Maintains strength from -253°C to 550°C

- Non-magnetic properties: Ideal for sensitive electronic applications

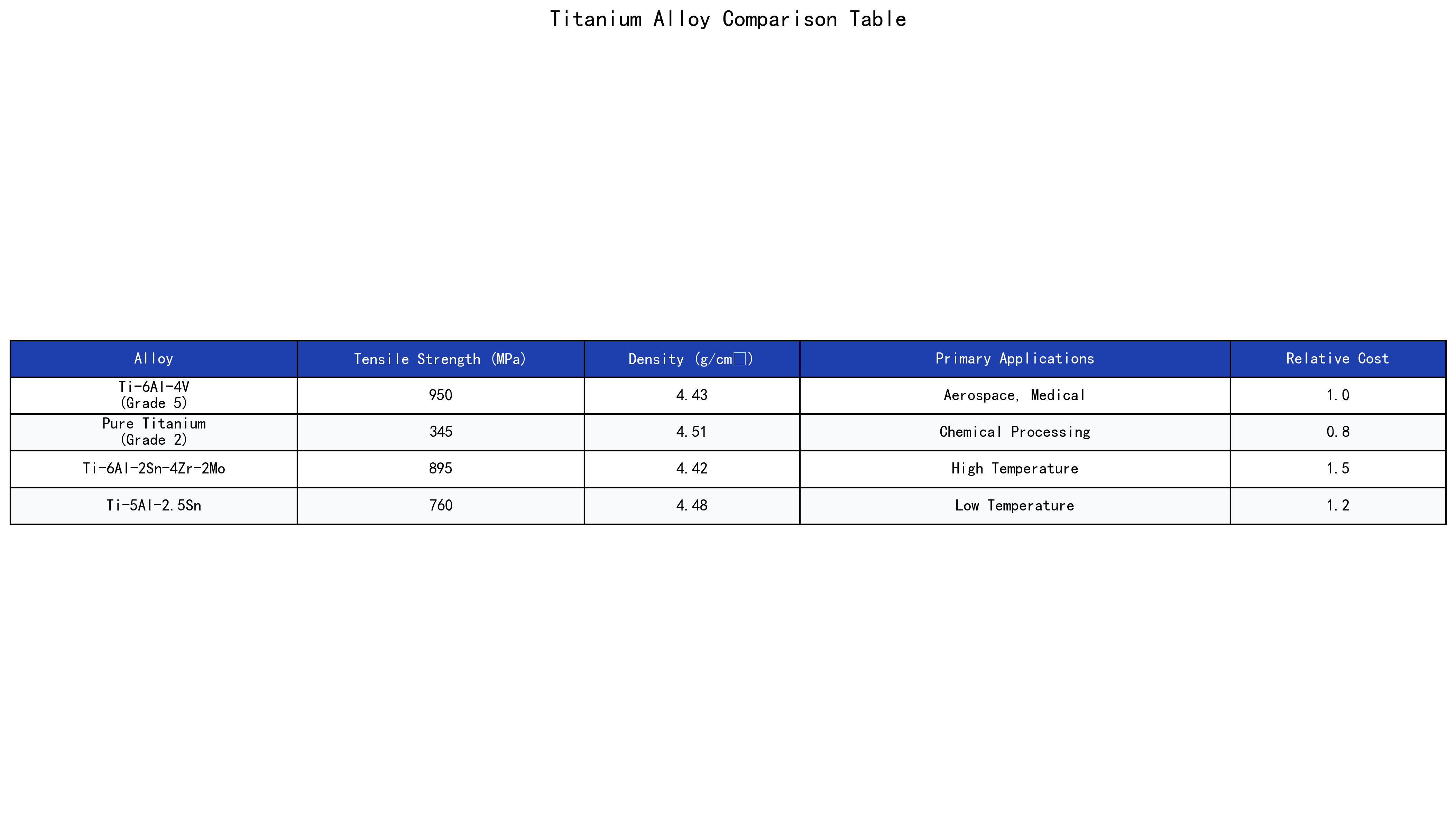

What are the main titanium alloys used in CNC machining?

The most common titanium alloys for CNC applications include:

Why is titanium more difficult to machine than aluminum?

Titanium’s machining challenges stem from:

- Low thermal conductivity: Heat concentrates at the cutting edge

- Chemical reactivity: Tends to weld to cutting tools at high temperatures

- High strength: Requires more cutting force

- Spring-back effect: Elastic modulus causes workpiece deflection

- Work hardening: Surface becomes harder during machining

What are the typical applications of titanium parts?

Titanium excels in these critical applications:

- Aerospace: Engine components, airframe structures, fasteners

- Medical: Dental implants, orthopedic devices, surgical instruments

- Marine: Propellers, heat exchangers, offshore equipment

- Chemical Processing: Reaction vessels, pipes, valves

- Sports Equipment: Bicycle frames, golf clubs, tennis rackets

How does titanium compare to aluminum in terms of cost and performance?

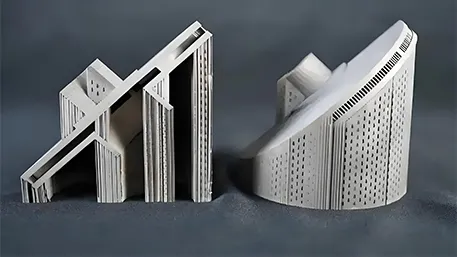

Practical Guide: Step-by-Step Process

Step 1: Material Selection

- Choose the appropriate titanium alloy based on application requirements

- Consider strength, corrosion resistance, and temperature needs

- Verify material certifications (ASTM B348, AMS 4928)

- Select proper stock size and form (bar, sheet, forging)

Step 2: CNC Machining Setup

- Machine Requirements: Rigid machine with high torque spindle

- Tool Selection: Carbide, ceramic, or CBN tools with sharp cutting edges

-

- Speed: 25-75 m/min (varies by alloy)

- Coolant System: High-pressure coolant (70-100 bar)

Step 3: Machining Process

- Roughing: Remove excess material with higher feed rates

- Semi-finishing: Improve dimensional accuracy

- Finishing: Achieve final tolerances (typically ±0.02mm)

- Deburring: Remove sharp edges and burrs

- Cleaning: Remove coolant residues and contaminants

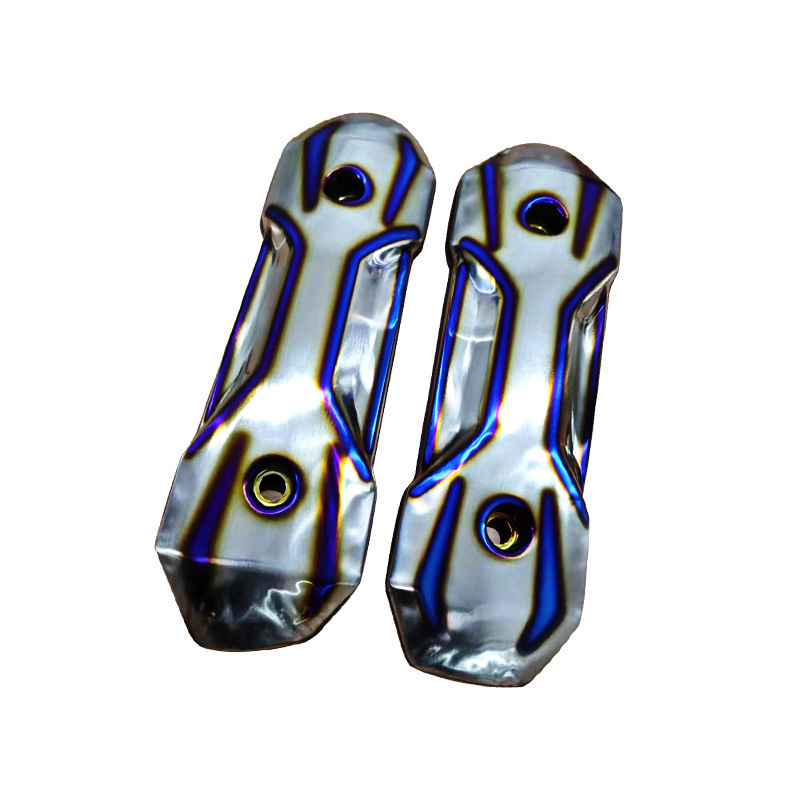

Step 4: Surface Treatment Options

- Mechanical Finishing: Polishing, sandblasting, tumbling

- Chemical Treatments: Pickling, passivation, anodizing

- Coatings: PVD, CVD, thermal spraying for enhanced performance

- Heat Treatment: Stress relieving, solution treating, aging

Step 5: Quality Control and Inspection

- Dimensional Inspection: CMM, micrometers, calipers

- Surface Analysis: Profilometers, visual inspection

- Material Testing: Hardness testing, metallography

- Non-destructive Testing: Ultrasonic, X-ray, dye penetrant

- Documentation: Complete traceability records

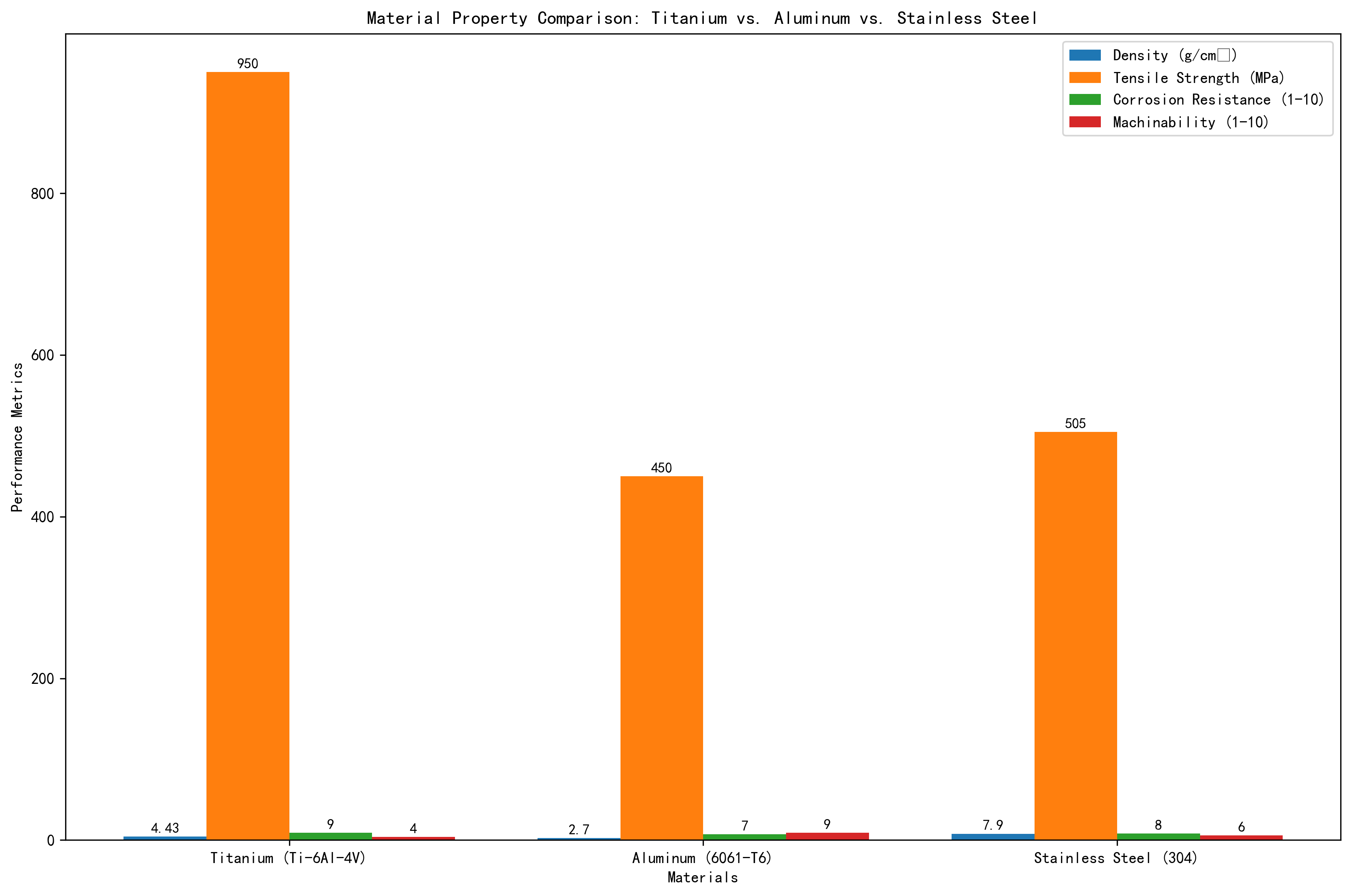

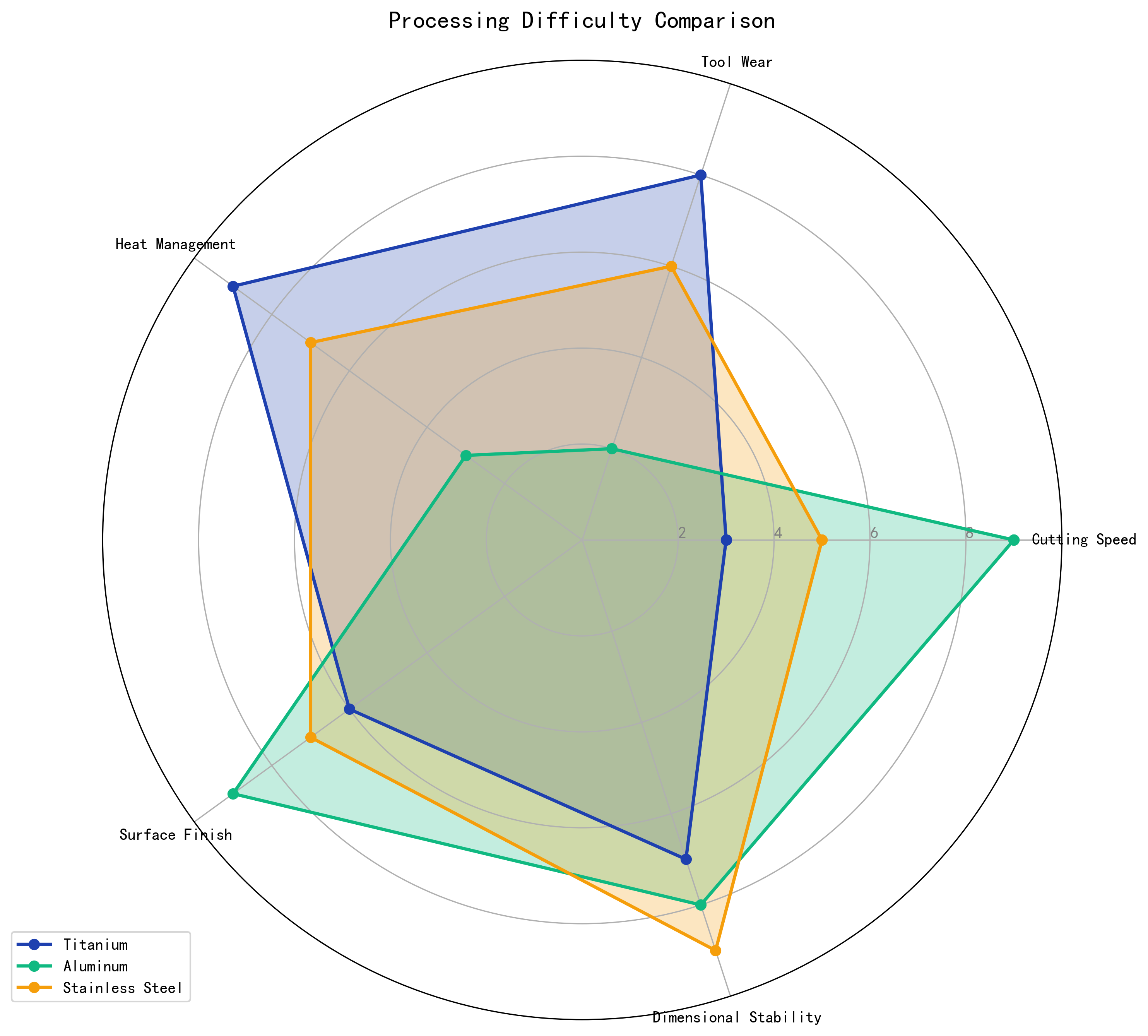

Service Comparison: Titanium vs. Other Metals

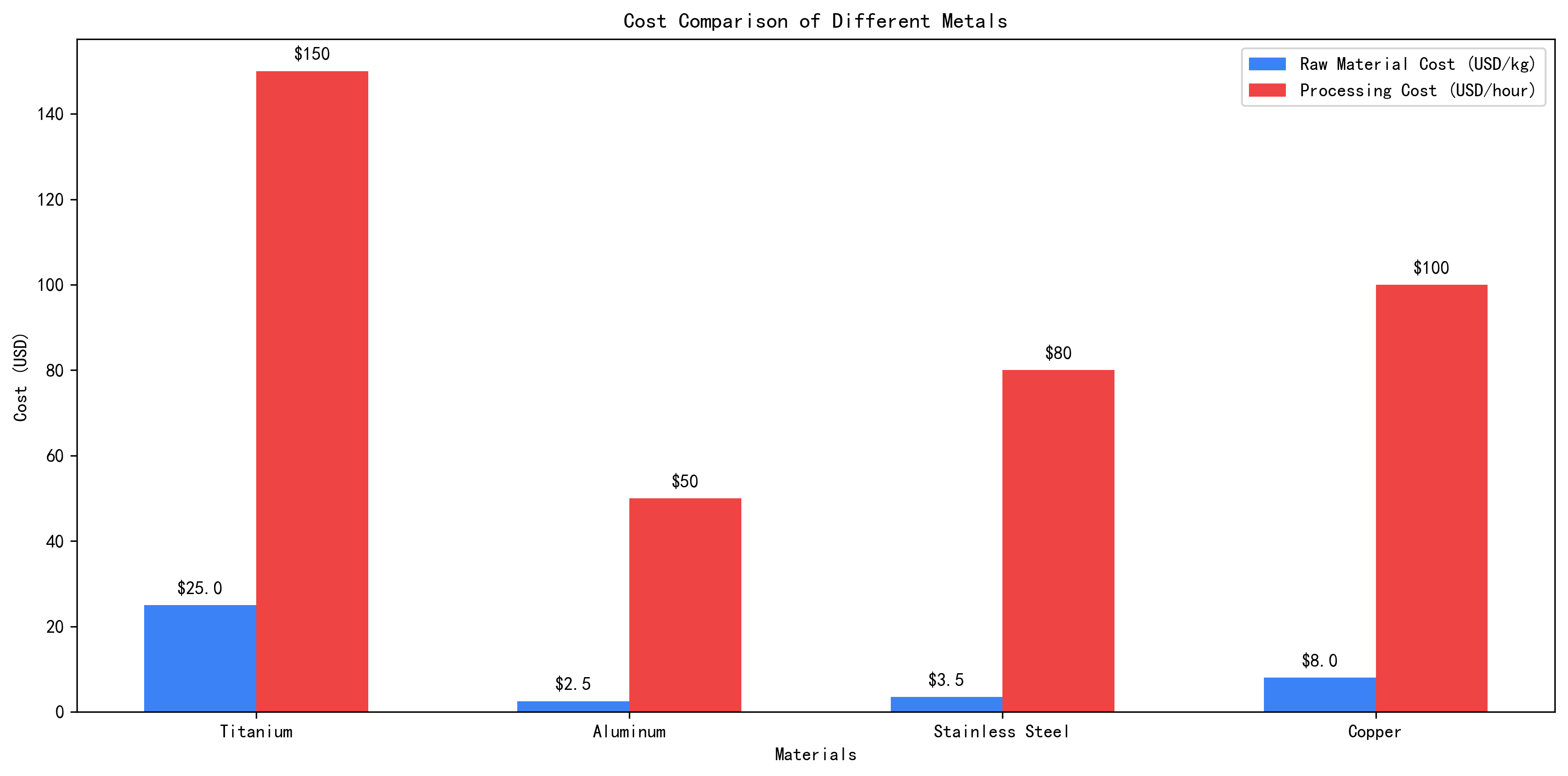

Cost Comparison

Processing Difficulty Comparison

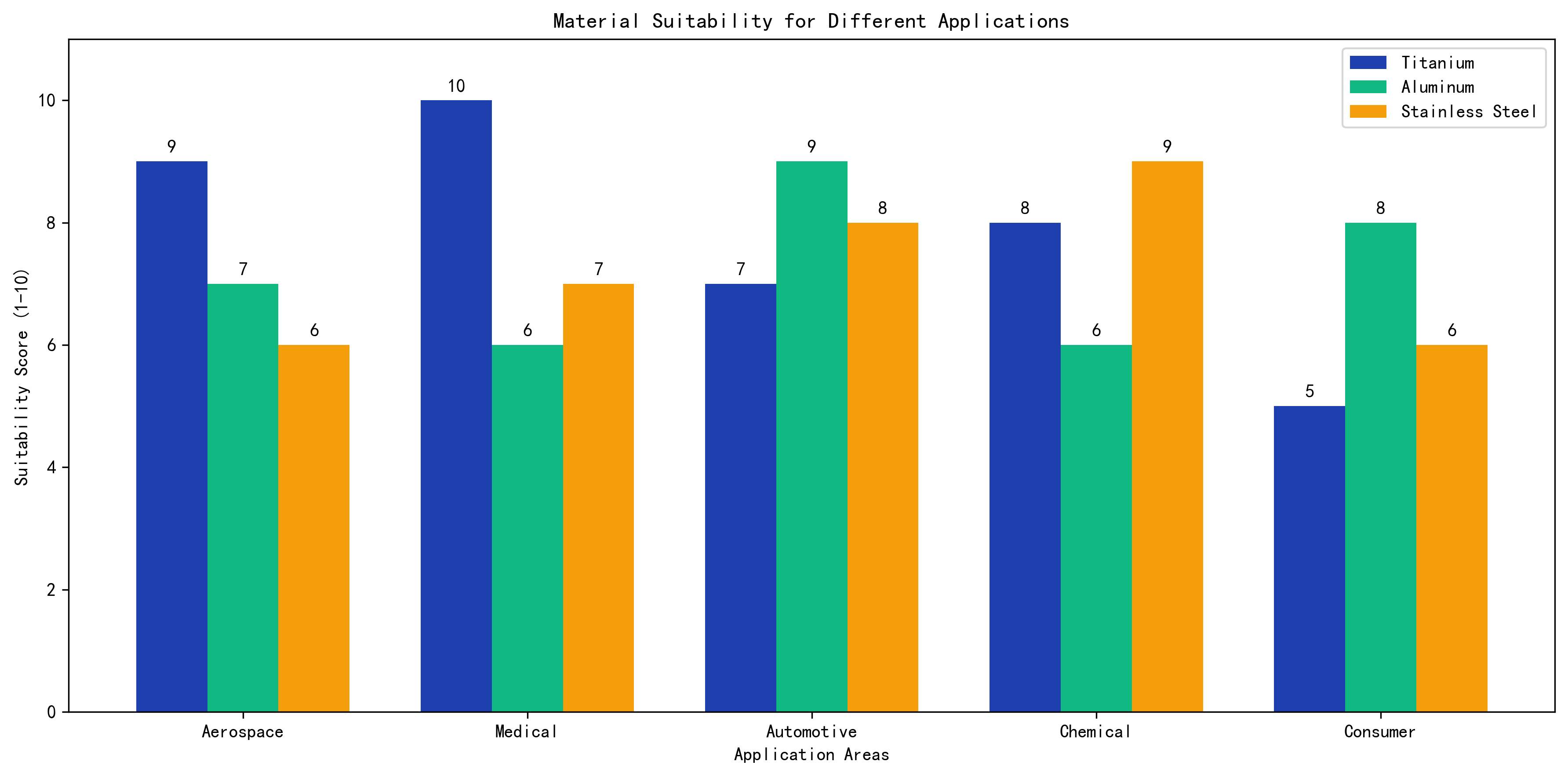

Application Suitability

Conclusion

CNC titanium alloy parts offer unmatched performance in critical applications where strength, weight, and reliability are paramount. While more challenging and expensive to produce than aluminum or steel, titanium’s unique properties justify the investment in applications ranging from aerospace to medical devices.

Key Takeaways:

- Choose titanium for applications requiring high strength-to-weight ratio

- Partner with experienced manufacturers for complex titanium machining

- Consider total lifecycle costs rather than just initial investment

- Leverage titanium’s biocompatibility for medical applications

- Utilize proper machining techniques to maximize quality and efficiency

As manufacturing technology continues to advance, titanium will play an increasingly important role in enabling the next generation of high-performance products across industries worldwide.