In the competitive beauty industry, packaging is more than just a container—it’s the first impression, the brand ambassador, and the silent storyteller that communicates quality, values, and aesthetic vision. Custom cosmetic plastic bottles have evolved into sophisticated brand assets that blend functionality with artistic expression, creating emotional connections with consumers while ensuring product integrity.

This article explores the art and science of custom cosmetic plastic bottle manufacturing, highlighting the unique requirements of beauty packaging, emerging design trends, and the specialized capabilities needed to transform creative concepts into market-ready products.

The Strategic Importance of Cosmetic Packaging

Cosmetic packaging serves multiple critical functions that distinguish it from other industries:

Brand Identity and Recognition

- Visual Storytelling: Packaging communicates brand personality, values, and positioning

- Shelf Impact: Stands out in crowded retail environments

- Unboxing Experience: Creates memorable first interactions with consumers

Consumer Psychology and Behavior

- 72% of consumers judge a product based on its packaging design

- Premium perception: High-quality packaging justifies higher price points

- Emotional connection: Design elements evoke desired feelings and aspirations

Functional Requirements

- Product protection: Preserves formulation integrity and shelf life

- User experience: Ergonomic design for ease of use

- Dispensing precision: Controlled application of products

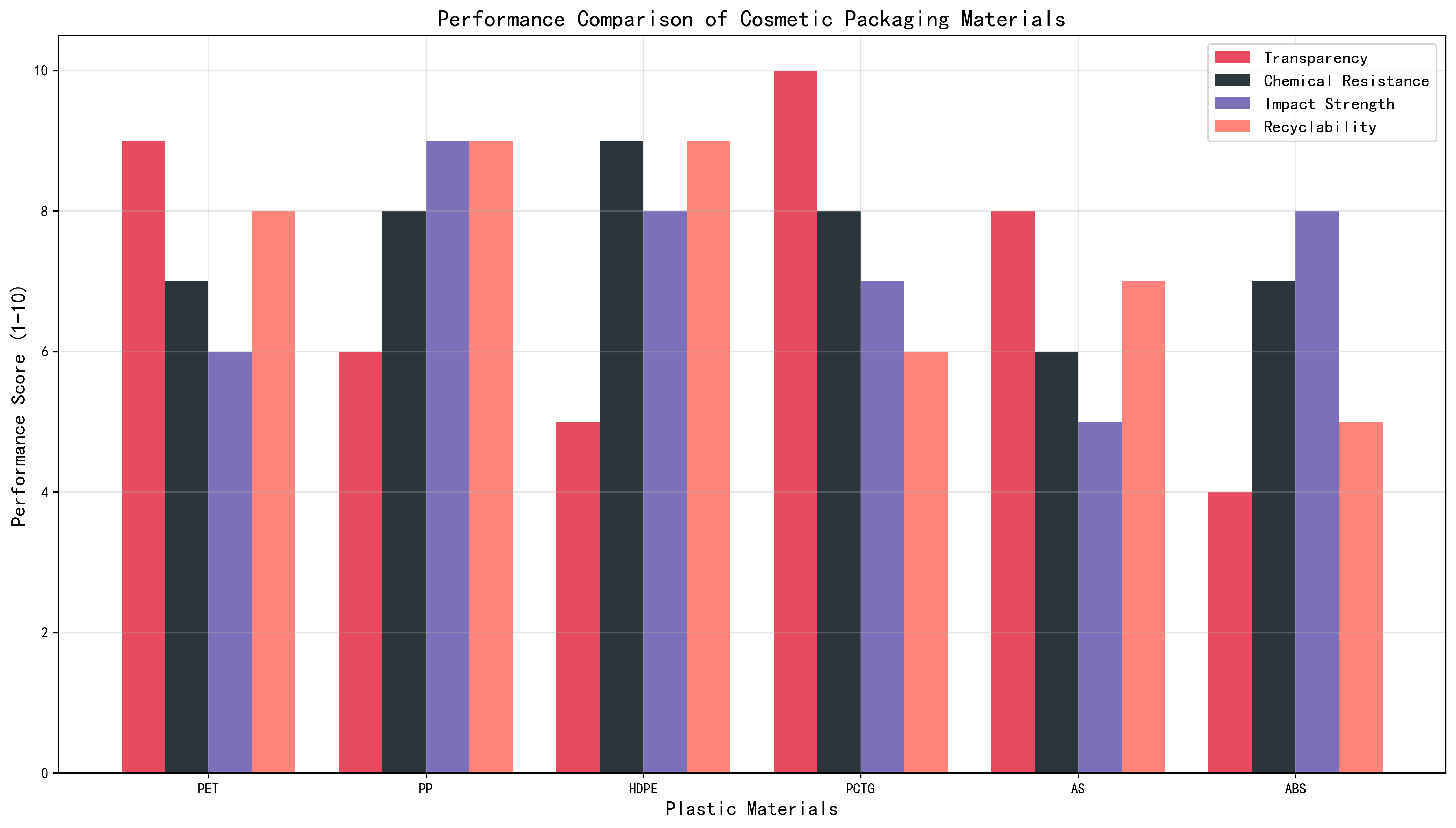

Material Science for Cosmetic Excellence

The selection of plastic materials for cosmetic packaging requires careful consideration of both aesthetic and functional requirements.

Premium Material Options

Polyethylene Terephthalate (PET)

- Aesthetic Appeal: Excellent transparency, high gloss finish

- Functional Benefits: Good barrier properties, lightweight, shatterproof

- Applications: Premium skincare bottles, fragrance containers, high-end serums

- Sustainability: 100% recyclable, widely accepted in recycling streams

Polypropylene (PP)

- Performance Features: Chemical resistance, impact strength, heat tolerance

- Design Flexibility: Matte or glossy finishes, various color options

- Applications: Lotion pumps, cream jars, travel-sized containers

- Advantages: Cost-effective, durable, autoclavable

High-Density Polyethylene (HDPE)

- Key Properties: Chemical inertness, moisture resistance, durability

- Visual Characteristics: Opaque to translucent, smooth surface

- Applications: Shampoo bottles, body wash containers, hair care products

- Benefits: Recyclable, impact resistant, lightweight

PCTG (Polycyclohexylene Dimethylene Terephthalate)

- Luxury Qualities: Glass-like clarity, high-end appearance

- Performance: Excellent chemical resistance, impact strength

- Applications: Premium serums, essences, high-value formulations

- Features: UV resistance, scratch resistance, recyclable

Sustainable Material Innovations

PCR (Post-Consumer Recycled) Plastics

- Environmental Benefits: Reduces plastic waste, lowers carbon footprint

- Performance: Maintains quality while demonstrating sustainability commitment

- Consumer Appeal: 60% of consumers willing to pay 10% more for sustainable packaging

Bio-Based Polymers

- Renewable Sources: Sugarcane-based plastics, plant-derived materials

- Carbon Neutral: Reduces reliance on fossil fuels

- Brand Value: Enhances eco-friendly positioning

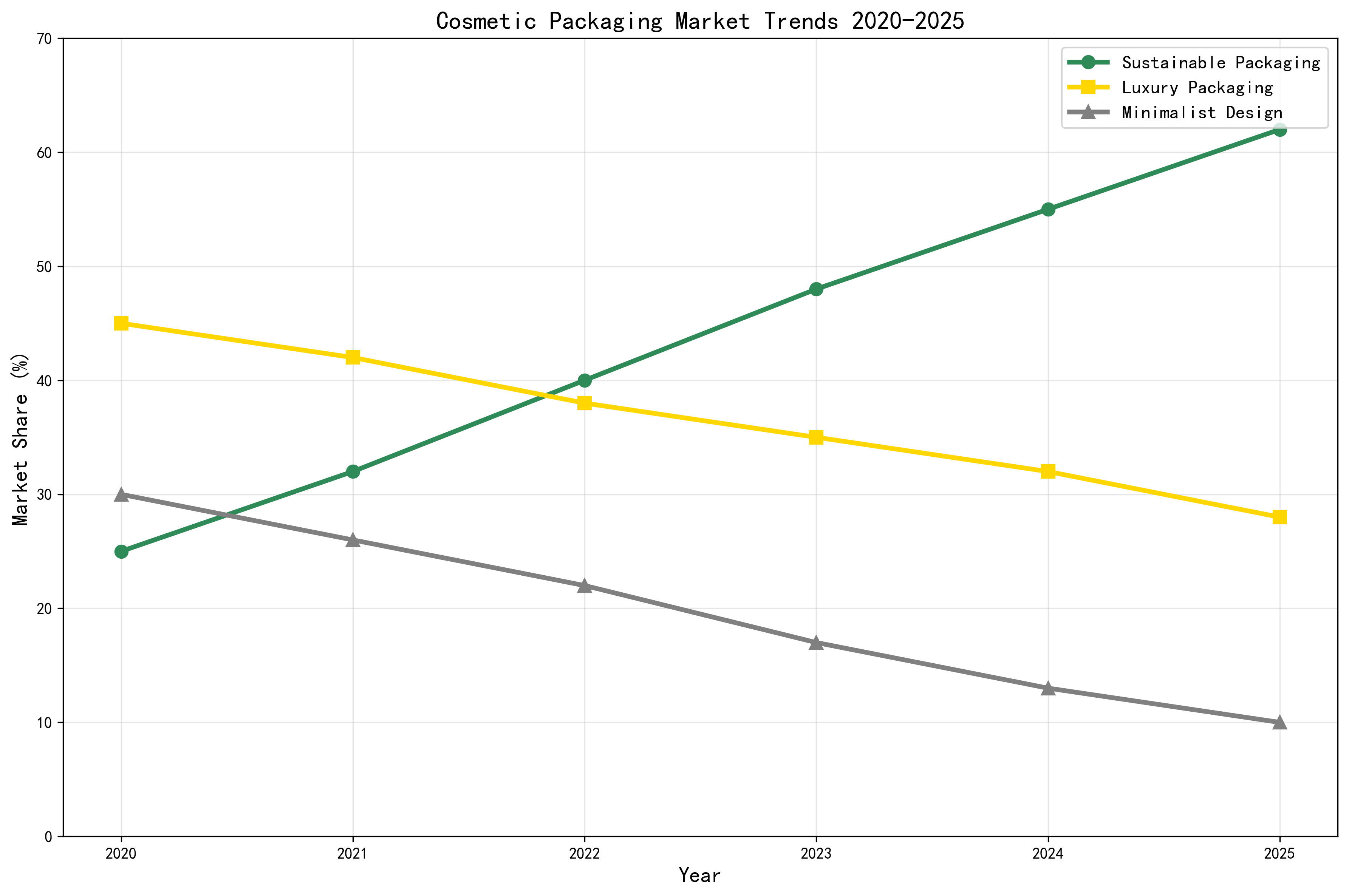

Design Trends and Aesthetic Evolution

The cosmetic packaging landscape is constantly evolving, driven by consumer preferences, technological advancements, and sustainability imperatives.

Dominant Design Directions

Sustainable Luxury

- Minimalist aesthetics with maximum impact

- Recyclable materials presented in premium finishes

- Refillable systems that combine sustainability with luxury experience

Bold Color Statements

- Vibrant hues that create instant visual impact

- Metallic accents for premium differentiation

- Ombre effects and gradient transitions

Tactile Experiences

- Matte finishes for sophisticated touch

- Textured surfaces that engage the senses

- Weighted designs that convey quality and substance

Innovative Shapes

- Asymmetrical forms that break traditional conventions

- Ergonomic contours for comfortable handling

- Modular systems that allow for brand extension

Customization Capabilities and Design Excellence

Comprehensive Design Services

Concept Development

- Brand alignment: Translating brand identity into packaging language

- Trend analysis: Incorporating current and emerging design directions

- Consumer insights: Understanding target audience preferences

Technical Engineering

- CAD modeling: Precision design for manufacturability

- Material selection: Matching properties to product requirements

- Prototype development: Rapid iteration and testing

Advanced Decoration Techniques

Surface Finishes

- Matte coating: Sophisticated, fingerprint-resistant finish

- Glossy polish: High-shine, reflective surfaces

- Soft-touch coating: Velvety texture for premium feel

Printing Technologies

- Screen printing: Vibrant colors, fine detail, long-lasting

- Hot stamping: Metallic accents, foil detailing

- Digital printing: Full-color graphics, variable data

Special Effects

- UV coating: Glossy highlights, protective layer

- Pearlescent finishes: Iridescent, light-reflective effects

- Embossing/debossing: Tactile logos and patterns

Dispensing Systems

Pump Mechanisms

- Airless pumps: Preserves formulation integrity, prevents contamination

- Spray pumps: Fine mist application for fragrances and toners

- Foam pumps: Creates luxurious lather for cleansers

Dropper Assemblies

- Glass pipettes: Premium presentation for serums and essences

- Plastic droppers: Cost-effective alternative with precision dosing

- Calibrated dispensers: Controlled product delivery

Manufacturing Excellence and Quality Assurance

Precision Manufacturing Processes

Injection Blow Molding

- Process control: Consistent wall thickness, dimensional accuracy

- Design flexibility: Complex shapes and intricate details

- Production efficiency: High-volume manufacturing capabilities

Extrusion Blow Molding

- Material efficiency: Optimized material usage

- Cost effectiveness: Economical for larger containers

- Design versatility: Wide range of sizes and configurations

Quality Control Standards

Visual Inspection

- Automated systems: High-speed defect detection

- Manual sampling: Detailed examination of critical features

- Color matching: Precise adherence to brand specifications

Performance Testing

- Leak testing: Ensuring product containment and safety

- Durability testing: Impact resistance and structural integrity

- Compatibility testing: Material interaction with formulations

Regulatory Compliance

- Global standards: FDA, EU, and international regulatory requirements

- Safety certifications: Material safety and product compliance

- Sustainability credentials: Environmental impact verification

Sustainability and Environmental Responsibility

Eco-Friendly Initiatives

Recyclable Solutions

- Single-material designs: Simplifying recycling processes

- Recycling instructions: Clear labeling for proper disposal

- Recycled content: Incorporating PCR materials

Circular Economy Approaches

- Refill systems: Reducing packaging waste through reuse

- Take-back programs: Closing the loop on packaging materials

- Biodegradable options: Compostable materials for certain applications

Environmental Impact Reduction

Energy Efficiency

- Renewable energy: Solar, wind power for manufacturing facilities

- Energy optimization: Process improvements to reduce consumption

- Carbon footprint tracking: Measuring and reducing environmental impact

Waste Minimization

- Lean manufacturing: Reducing production waste

- Material optimization: Lightweighting without compromising quality

- Water conservation: Efficient use of water resources

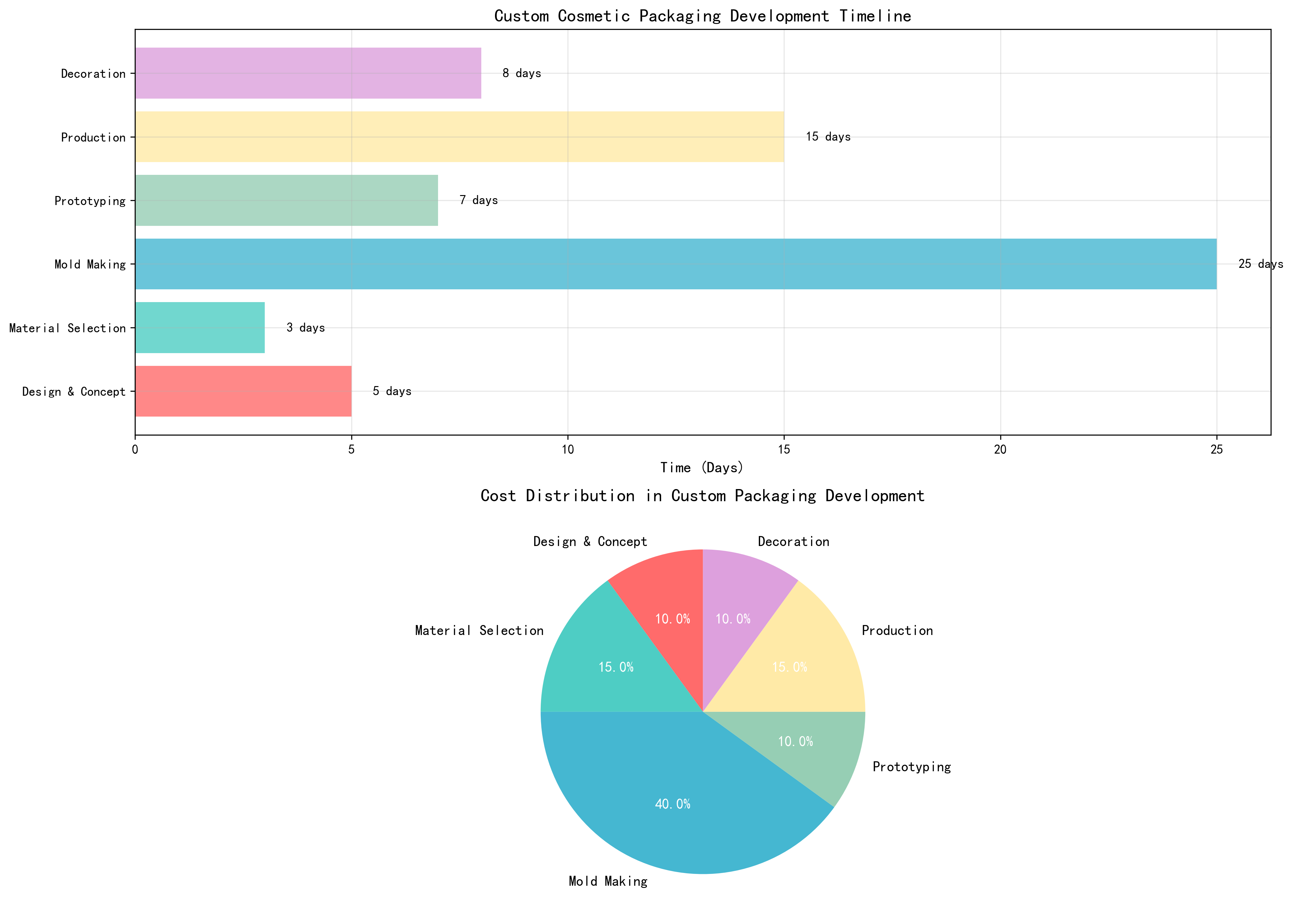

Customization Process: From Concept to Creation

Step-by-Step Customization Journey

1. Design & Concept Development (5 days)

- Brand brief analysis: Understanding brand identity and objectives

- Creative concepting: Developing initial design directions

- Technical feasibility: Assessing manufacturability of concepts

2. Material Selection (3 days)

- Property matching: Selecting materials based on product requirements

- Aesthetic evaluation: Assessing visual and tactile qualities

- Cost optimization: Balancing quality with budget considerations

3. Mold Making (25 days)

- Tool design: Precision engineering of molds

- Prototype tooling: Creating initial molds for testing

- Production tooling: Scaling up for mass production

4. Prototyping (7 days)

- Sample production: Creating physical prototypes

- Design validation: Testing form, fit, and function

- Consumer testing: Gathering feedback on design concepts

5. Production (15 days)

- Manufacturing setup: Preparing production lines

- Quality monitoring: Ensuring consistency and quality

- Volume scaling: Meeting production quantity requirements

6. Decoration (8 days)

- Surface finishing: Applying desired textures and coatings

- Printing application: Adding brand graphics and information

- Final assembly: Combining components into finished products

Why Choose Xiamen Goldcattle for Your Cosmetic Packaging Needs

When it comes to custom cosmetic plastic bottle manufacturing, Xiamen Goldcattle offers a unique combination of technical expertise, design excellence, and manufacturing capabilities that set us apart in the beauty packaging industry.

Design Excellence

- Creative capabilities: Translating brand vision into tangible designs

- Trend awareness: Incorporating current and emerging design directions

- Technical knowledge: Balancing aesthetics with functionality

Manufacturing Prowess

- State-of-the-art facilities: 100+ advanced CNC machines for precision manufacturing

- Process expertise: Mastery of injection blow molding and extrusion techniques

- Quality control: Rigorous standards ensuring consistent quality

Material Innovation

- Material science knowledge: Deep understanding of plastic properties and applications

- Sustainable solutions: Offering eco-friendly materials and processes

- Custom formulation: Developing specialized materials for unique requirements

Service Advantages

- One-stop solution: From design to delivery under one roof

- Quick turnaround: 1-30 day production lead times

- Technical support: Dedicated engineering team for product development

Global Reach

- International certifications: Meeting global regulatory requirements

- Export experience: Serving clients in North America, Europe, Asia, and beyond

- Logistics expertise: Efficient delivery to global destinations

Transform Your Brand with Exceptional Packaging

In the beauty industry, packaging is your brand’s most powerful communication tool. It’s the first touchpoint with consumers, the silent salesperson on the shelf, and the lasting impression that builds brand loyalty.

At Xiamen Goldcattle, we understand the critical role that packaging plays in cosmetic product success. Our 26 years of manufacturing experience, combined with our passion for design and innovation, make us the ideal partner for creating packaging that not only protects your products but also elevates your brand.

Contact us today to discuss how our custom cosmetic plastic bottle solutions can help you create packaging that resonates with consumers, differentiates your brand, and drives business growth.

Ready to Get Started?

- Share your vision: Tell us about your brand, products, and packaging goals

- Receive expert consultation: Get professional advice on materials, designs, and processes

- Review design concepts: Evaluate initial design directions and provide feedback

- Approve prototypes: Test and approve physical samples before full production

- Launch your products: Bring your vision to life with high-quality packaging

With Xiamen Goldcattle, you’re not just getting a packaging supplier—you’re gaining a strategic partner dedicated to helping your beauty brand succeed in today’s competitive marketplace.

Xiamen Goldcattle Industrial & Trade Co., Ltd.

Crafting Beauty Through Precision Packaging

26 Years of Excellence in Cosmetic Packaging Solutions

This article provides general information about custom cosmetic plastic bottle services. For specific technical requirements and design guidance, please consult with qualified professionals in the cosmetic packaging industry.