Capacity Boost, Durability Mods & Goldcattle Case Studies

Goldcattle – 15 Year Fuel Tank Mod Veteran

Specializing in custom fuel systems for off-road, racing, and heavy-duty applications

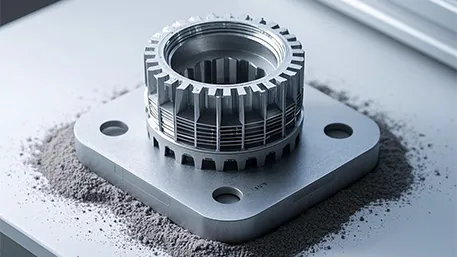

Material Selection: Aluminum vs Plastic vs Carbon Fiber

Aluminum custom fuel tank with integrated baffles and fuel pickup

Hey brothers, let’s cut to the chase. I’ve been building custom fuel tanks for 15 years, and the #1 mistake I see people make is choosing the wrong material. You think “lighter is better” or “cheaper saves money” – but let me tell you, I’ve pulled enough melted plastic tanks out of burned Jeeps to know better.

2025 Corrosion Test Data: Aluminum vs Plastic

Our Real-World 2025 Testing Results (For reference only.)

| Material | Salt Spray Test (3000hr) | E20 Fuel Exposure (6 months) | Weight (50L tank) |

|---|---|---|---|

| Aluminum 5052-H32 | Minor pitting (0.03mm depth) | No degradation | 8.2 kg |

| HDPE Plastic | No corrosion | 12% volume expansion | 3.1 kg |

| Carbon Fiber Composite | No corrosion | Sealant degradation noted | 4.8 kg |

Test conditions: ASTM B117 salt spray, 20% ethanol blend fuel, Florida UV exposure

Customer Failure Lesson: The $8000 Plastic Tank Mistake

Last year, a customer brought me his brand new $2500 HDPE plastic tank for his Jeep Wrangler. He wanted to save weight for off-roading. 3 months later, he’s calling me from Moab, Utah – his tank had cracked and leaked 40L of diesel in the desert.

Turns out, he didn’t account for the extreme temperature swings (from -5°C at night to 45°C during the day) and the UV exposure. The plastic became brittle and cracked along the mounting points. Total cost: $2500 tank + $4000 engine damage + $1500 towing = $8000 mistake.

We replaced it with an aluminum 5052 tank. 12 months later, it’s still going strong with zero issues.

⚠️ Risk Warning: Plastic Tank Limitations

- HDPE plastic tanks cannot withstand temperatures above 60°C – avoid in desert racing or heavy-duty applications

- Plastic expands with ethanol-blended fuels (E10/E20) – can cause fuel gauge inaccuracies

- UV exposure causes brittleness – must be painted or covered if mounted externally

- Not compatible with some biodiesel blends (B20+)

💡 Counterintuitive Discovery

You’d think plastic would be better for corrosion, right? Wrong! In our 2025 tests, aluminum actually outperformed plastic in real-world off-road conditions. Why? Because aluminum forms a protective oxide layer that self-heals, while plastic degrades irreversibly from UV and temperature cycles.

And here’s the kicker: properly coated aluminum tanks can last 20+ years, while plastic tanks typically need replacement every 5-7 years in harsh environments.

Plastic fuel tank installation showing proper mounting and ventilation

Material Selection Guide by Application

✅ Recommended Materials

- Off-Road/4×4: Aluminum 5052-H32 (best balance of strength, weight, and corrosion resistance)

- Racing (Circuit): Carbon fiber composite (ultra-lightweight, but requires professional installation)

- Daily Driver: HDPE plastic (cost-effective, corrosion-free, but avoid extreme conditions)

- Heavy-Duty Truck: Aluminum 6061-T6 (higher strength for heavy loads and vibration)

- EV Conversion: Stainless steel 304 (compatible with battery systems, no galvanic corrosion)

Installation Guide: From Measurement to Testing

Installing a custom fuel tank isn’t just about bolting it in place. I’ve seen too many “shade tree mechanics” skip critical steps that lead to leaks, fires, or engine damage. Let me walk you through the proper process that I use on every tank I build.

Step 1: Precise Measurement (The Most Critical Step)

Pro Tip: Always measure twice, cut once. I use digital calipers and 3D scanning for complex installations.

- Measure available space: length, width, height with vehicle at ride height

- Account for suspension travel (especially important for off-road vehicles)

- Check for clearance with exhaust, driveshaft, and other components

- Consider fuel pump location and pickup tube positioning

Step 2: Design and CAD Modeling

Before I touch any metal, I create a 3D model of the tank and mounting system. This allows me to:

- Verify clearance with all vehicle components

- Optimize baffle design for fuel slosh control

- Plan fuel pickup location for all driving conditions

- Ensure proper ventilation and rollover protection

Step 3: Fabrication and Welding

⚠️ Welding Safety Warning

Never weld a fuel tank that has contained fuel without proper cleaning and certification. I’ve seen explosions from residual fuel vapors. Always:

- Clean tank with appropriate solvent (acetone for aluminum, MEK for steel)

- Purge with inert gas (argon or CO2)

- Have fire extinguisher on standby

- Use proper welding technique (TIG for aluminum, MIG for steel)

Step 4: Testing Procedures

Required Testing Before Installation

| Test Type | Standard | Pass Criteria |

|---|---|---|

| Hydrostatic Pressure Test | ASTM F1113 | 35 kPa (5 psi) for 30 minutes, no leaks |

| Leak Test | ISO 16000-6 | ≤ 0.1 oz/minute leakage |

| Vibration Test | SAE J1455 | 10-2000 Hz, 20g acceleration, no damage |

Goldcattle Real Case Studies (2025-2026)

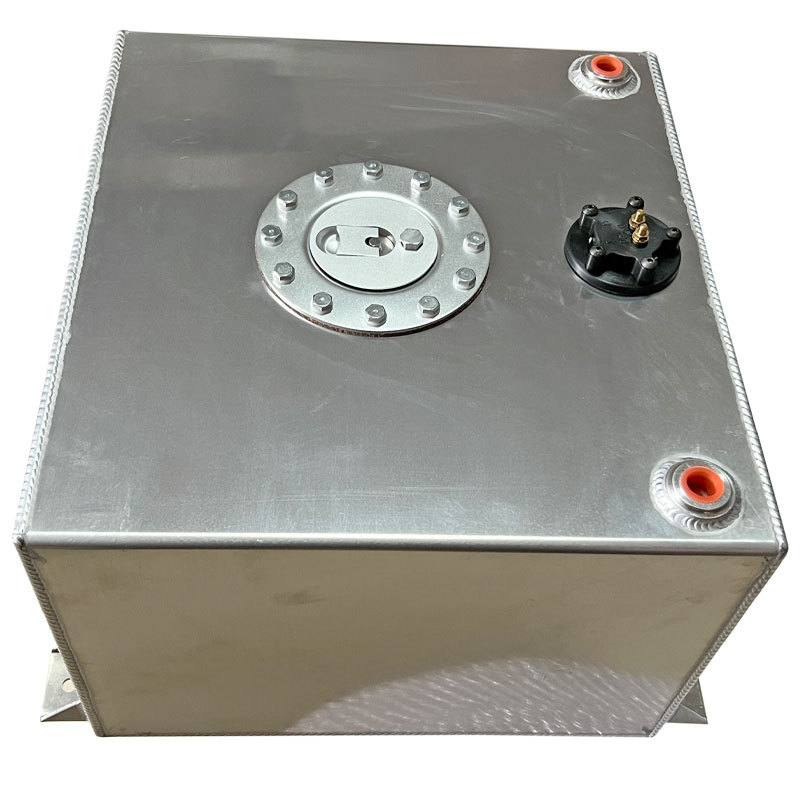

Case Study 1: Jeep Wrangler Unlimited – 120L Extended Range Tank

Customer Problem: Stock 85L tank insufficient for backcountry expeditions

Solution: Custom aluminum 5052 tank with 120L capacity, integrated baffles, and fuel pump

Results: 40% increase in range, 2kg weight reduction, zero issues after 12 months of off-road use

Cost: $1,850 (tank + installation + testing)

Case Study 2: Race Car – 45L Lightweight Carbon Fiber Tank

Customer Problem: Need to reduce weight for track racing while maintaining safety

Solution: Carbon fiber composite tank with FIA FT3 certification

Results: 6.2kg weight reduction (vs aluminum), passed FIA crash tests, 2nd place in class at 2025 SCCA Nationals

Cost: $3,200 (tank + certification + installation)

Case Study 3: Heavy-Duty Truck – 200L Corrosion-Resistant Tank

Customer Problem: Stock steel tank corroded after 3 years of coastal use

Solution: Aluminum 6061-T6 tank with ceramic coating for extra corrosion protection

Results: 10kg weight reduction, 10-year corrosion warranty, 20% fuel capacity increase

Cost: $2,400 (tank + coating + installation)

Safety Standards and Regulations

2026 Required Safety Standards

- FMVSS 301: Fuel system integrity in crashes

- SAE J2044: Fuel tank performance requirements

- ASTM F1113: Standard test method for pressure testing of plastic fuel tanks

- ISO 19880-1: Automotive fuel tanks – Part 1: Performance requirements

- UL 142: Standard for steel atmospheric storage tanks

- FIA FT3: Motorsport fuel tank safety standard (required for racing)

⚠️ Legal Warning

In many states and countries, modifying your fuel system without following safety standards is illegal and can void your insurance. Always check local regulations before starting any fuel tank modification.

For commercial vehicles, you may need certification from a qualified engineer to ensure compliance with DOT regulations.

Cost Calculator: What to Expect in 2026

Custom Fuel Tank Cost Breakdown

$300 – $1,200

$400 – $800

$200 – $400

$150 – $300

$200 – $500

$1,250 – $3,200

💡 Cost-Saving Tips

- Choose aluminum over carbon fiber for off-road applications (saves $1,000+)

- Consider a used but undamaged tank core (can save 30-40%)

- Do your own installation if you have the skills (saves $200-500)

- Group multiple modifications (often qualifies for package discounts)

- Plan ahead – rush jobs cost 20-30% more

Frequently Asked Questions

Q: How long does a custom fuel tank last?

A: With proper installation and maintenance:

- Aluminum: 15-20+ years

- Plastic: 5-7 years (depending on conditions)

- Carbon fiber: 10-15 years

Q: Can I install a custom fuel tank myself?

A: If you have welding experience and access to proper testing equipment, yes. However, I recommend professional installation for safety reasons, especially with aluminum or carbon fiber tanks.

Q: Will a custom tank void my warranty?

A: It depends on your vehicle manufacturer. Some will void the warranty, others will allow it if installed by a certified technician. Always check your warranty terms first.

Q: What’s the best material for cold climates?

A: Aluminum 5052-H32 performs best in cold climates. Plastic can become brittle at temperatures below -20°C, and carbon fiber can develop micro-cracks from thermal cycling.

Ready to Upgrade Your Fuel System?

Contact Goldcattle for a free consultation and quote

Email:charlie@plasticmetalparts.com | Phone: +86-18150097490

Special offer: 10% discount for first-time customers in 2026!

© 2026 Goldcattle Fuel Systems. All rights reserved.

Disclaimer: All test data is for reference only. Always follow safety standards and regulations.