Why Custom Plastic Keyboard Molds Matter

In today’s competitive keyboard market, standing out from the crowd requires more than just unique branding. It requires a product that delivers exceptional performance, comfort, and durability. That’s where custom plastic keyboard molds come in.

From my 15 years in the industry, I’ve seen firsthand how custom molds can transform a good keyboard into an exceptional one. Standard off-the-shelf molds limit design creativity and often compromise on quality. Custom molds, on the other hand, allow manufacturers to create keyboards that perfectly match their vision.

✅ Full design freedom for unique keycap profiles and layouts

✅ Optimized for specific typing feel and sound characteristics

✅ Higher precision and consistency across all components

✅ Integration of advanced features like backlighting and ergonomic designs

✅ Better overall quality and durability compared to mass-produced keyboards

Whether you’re a gaming keyboard manufacturer looking to create the perfect typing experience or a business seeking durable keyboards for your employees, custom plastic keyboard molds offer unmatched flexibility and quality.

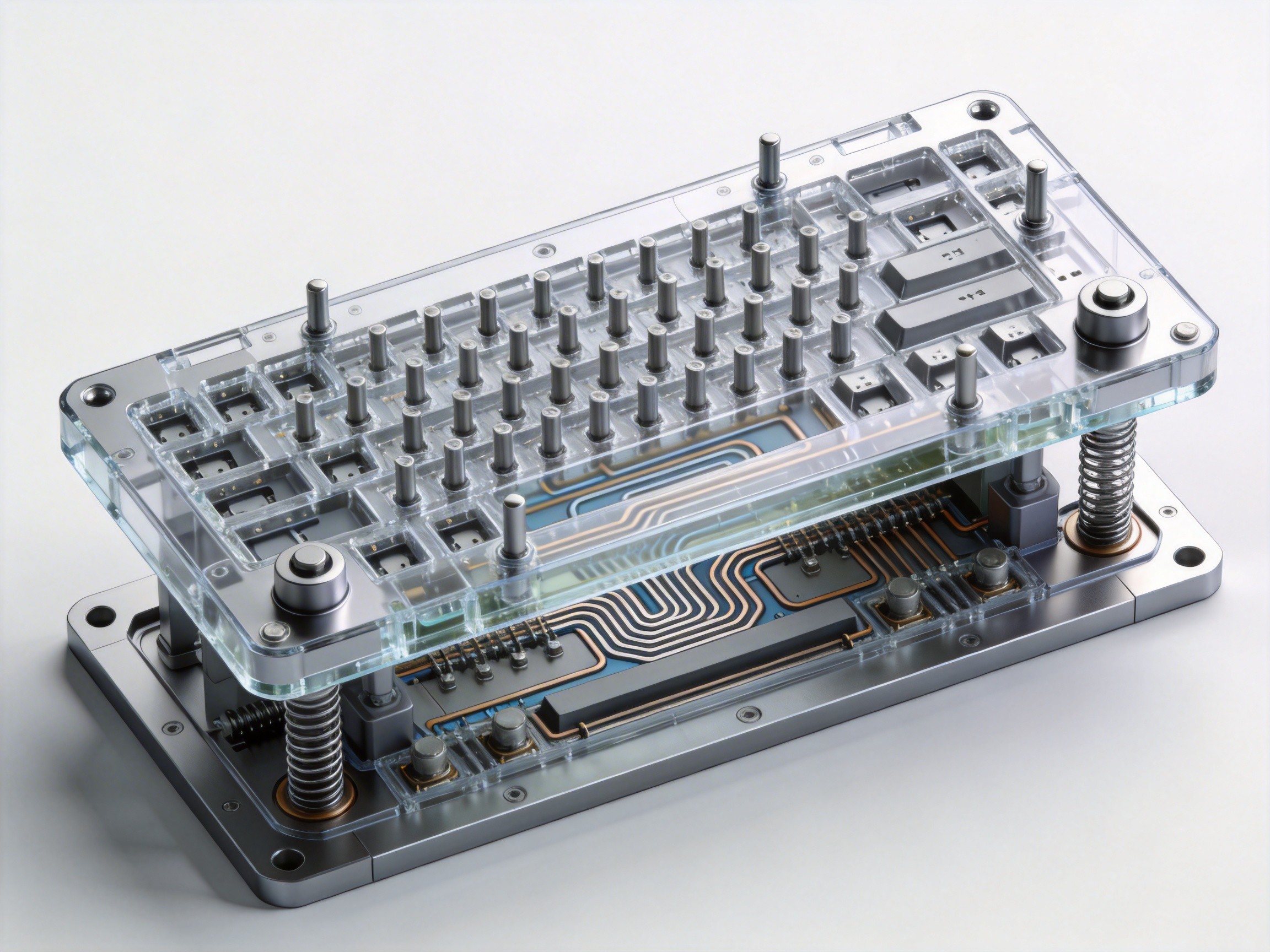

Custom Plastic Keyboard Injection Mold Design and Manufacturing

The core of any high-quality custom keyboard lies in its injection mold design. This is where functionality meets aesthetics, and every detail matters.

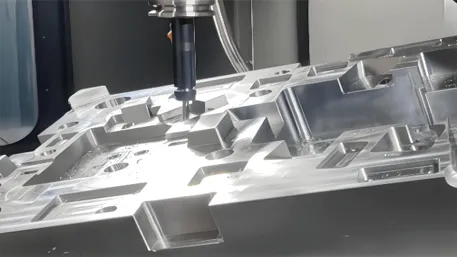

2. Mold Manufacturing Processes

Creating a custom keyboard mold is a multi-step process that requires precision engineering and attention to detail.

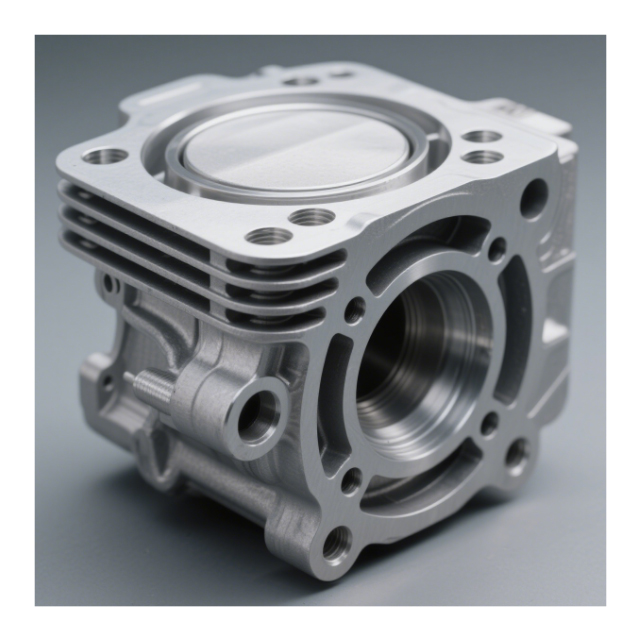

3. Mold Materials and Their Properties

The choice of mold material directly impacts the quality, durability, and cost of the finished product.

| Material | Key Properties | Typical Applications | Cost Range |

|---|---|---|---|

| P20 Tool Steel | Good hardness, machinable, moderate corrosion resistance | Medium-volume production, general purpose | Medium |

| H13 Hot Work Steel | Excellent heat resistance, high hardness, durable | High-volume production, high-temperature plastics | High |

| S136 Stainless Steel | Excellent corrosion resistance, polished finish | High-quality surface requirements, medical applications | High |

| Aluminum (7075) | Lightweight, good thermal conductivity, less durable | Low-volume production, prototyping | Low to Medium |

4. Plastic Keyboard Manufacturing Processes

Once the mold is ready, the actual keyboard production begins using injection molding technology.

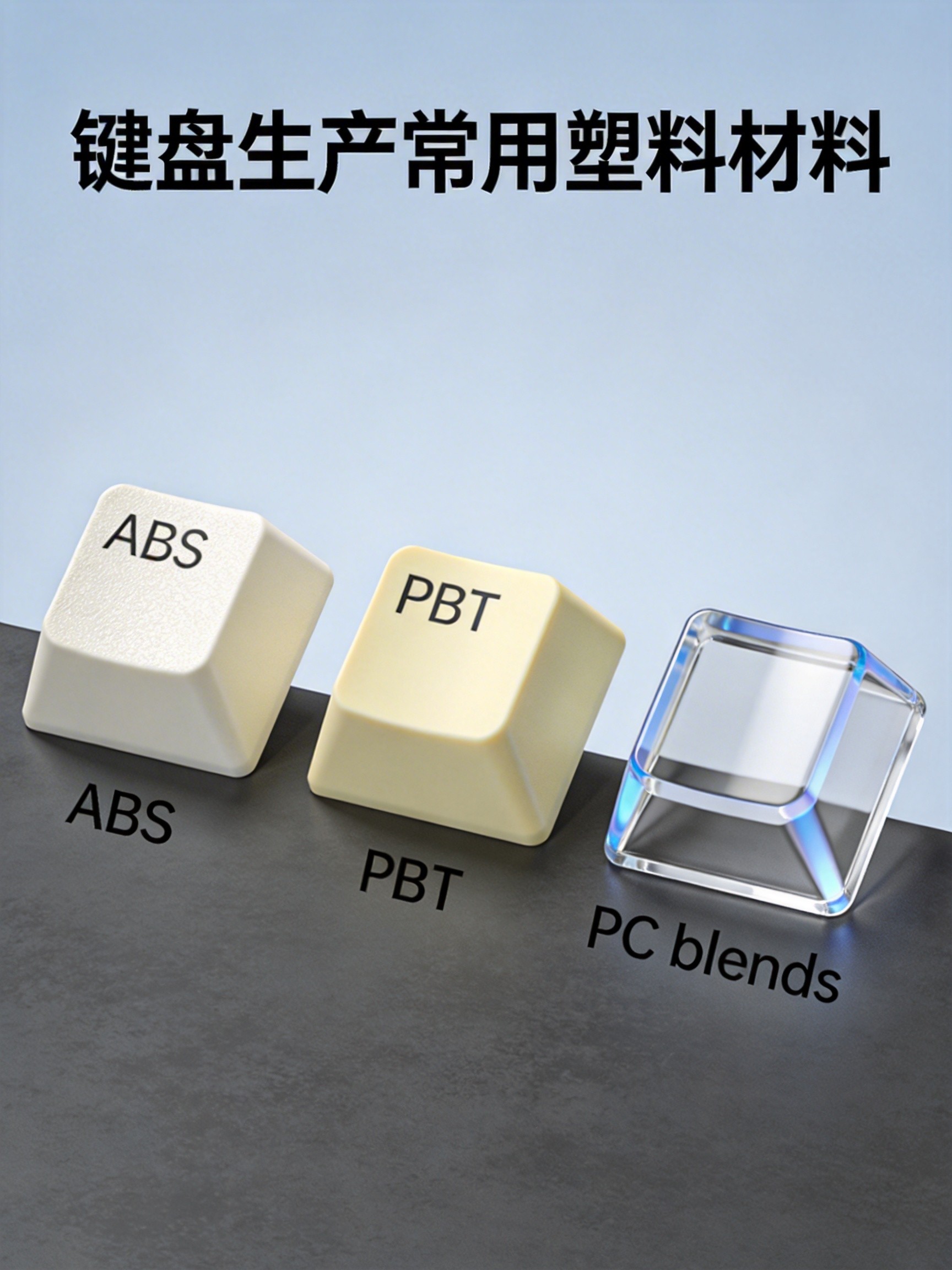

5. Keyboard Material Selection Guide

The choice of plastic material significantly affects the keyboard’s feel, sound, and durability.

| Material | Typing Feel | Sound Profile | Durability | Best For |

|---|---|---|---|---|

| ABS (Acrylonitrile Butadiene Styrene) | Smooth, slightly soft | Deep, resonant | Good (prone to shine over time) | Budget-friendly keyboards, gaming keyboards |

| PBT (Polybutylene Terephthalate) | Textured, slightly stiff | Crisp, clear | Excellent (resistant to shine) | Premium mechanical keyboards, heavy use |

| PC (Polycarbonate) | Smooth, rigid | Medium pitch | Very good (impact-resistant) | Transparent keycaps, keyboard housings |

| POM (Polyoxymethylene) | Smooth, low friction | Quiet, muffled | Excellent (wear-resistant) | Key stems, sliding components |

| TPU (Thermoplastic Polyurethane) | Soft, rubbery | Muffled, quiet | Good (flexible) | Wrist rests, ergonomic components |

6. Custom Plastic Keyboard Mold Process

Creating a custom keyboard involves a structured process that starts with design and ends with a finished product.

7. Understanding Injection Mold Costs

While exact costs vary based on complexity and volume, there are several factors that influence mold pricing:

- Design Complexity: More intricate designs require more engineering time and machining effort.

- Mold Material: High-quality tool steels cost more but offer longer mold life.

- Production Volume: Higher volumes allow for more cost-effective mold amortization.

- Surface Finish: Mirror finishes or specialized textures require additional processing.

- Additional Features: Hot runner systems, ejector pins, and cooling channels add to the cost.

As a general guide, custom keyboard molds can range from moderate to significant investments, depending on your specific requirements. For precise pricing, it’s best to consult with a mold manufacturing expert who can provide a detailed quote based on your design specifications.

8. Plastic Keyboard Surface Treatment Techniques

Surface treatments can enhance the look, feel, and durability of custom keyboards.

Texturing

- Sandblasting: Creates a uniform matte finish for reduced shine and better grip.

- Chemical Etching: Produces controlled textures for enhanced tactile feedback.

- Laser Engraving: Creates precise, durable legends on keycaps.

Coatings

- UV Coating: Adds a protective layer that resists scratches and wear.

- Rubberized Coating: Provides a soft, comfortable grip on keyboard housings.

- Anti-Scratch Coating: Protects keycaps from daily wear and tear.

Decorative Techniques

- Double Shot Molding: Creates durable legends that won’t fade over time.

- In-Mold Decorating: Integrates graphics directly into the plastic during molding.

- Pad Printing: Adds logos and text to keyboard components.

9. How to Customize Your Own Plastic Keyboard

Creating a custom keyboard is an exciting process that allows you to design a product perfectly suited to your needs.

Step 1: Define Your Requirements

Start by outlining what you need from your custom keyboard:

- Use Case: Gaming, typing, programming, or general use?

- Layout: Standard TKL, ergonomic, or custom layout?

- Keycaps: Material, profile, and color preferences?

- Switches: Linear, tactile, or clicky switches?

- Budget: What is your target price point?

Step 2: Work with Experienced Engineers

Partner with a manufacturing company that specializes in custom keyboard production. Look for:

- Experience: A track record of successful custom keyboard projects.

- Expertise: Engineers who understand both design and manufacturing constraints.

- Communication: Clear communication throughout the design process.

- Flexibility: Willingness to adjust designs based on your feedback.

Step 3: Prototyping and Testing

Always prototype before full production:

- Functionality Testing: Ensure all keys work correctly and the layout is comfortable.

- Durability Testing: Test for wear resistance and longevity.

- User Feedback: Get feedback from potential users to identify improvements.

Step 4: Final Production

Once the prototype is approved, move into full production:

- Quality Control: Implement rigorous inspection at every stage.

- Batch Testing: Regularly test samples from production runs.

- Documentation: Keep detailed records of each production batch.

Common Questions About Custom Keyboard Molding

What is the typical lead time for custom keyboard molds?

Depending on complexity, custom keyboard molds usually take 4-8 weeks from design approval to production-ready.

What is the expected mold lifespan?

High-quality tool steel molds can produce hundreds of thousands to millions of parts before needing replacement.

Can I modify an existing keyboard design?

Yes, existing designs can be modified to meet specific requirements, though full custom design often provides better results.

What file formats are needed for custom mold design?

Standard formats include STEP, IGES, and STL files. Experienced manufacturers can work with most common 3D file formats.

Is it possible to produce small batches with custom molds?

Yes, custom molds can be used for both small-batch prototyping and large-scale production.

How do I choose between 2K molding and single-shot molding?

2K molding is ideal for complex designs with multiple materials, while single-shot molding is more cost-effective for simpler parts.

What certifications should I look for in a manufacturer?

Look for ISO 9001 certification, which ensures consistent quality management processes.

Partner with Experts for Your Custom Keyboard Project

At Xiamen Goldcattle, we specialize in creating high-quality custom plastic keyboard molds and finished products. With over 15 years of experience in precision manufacturing, we have the expertise to bring your keyboard vision to life.

Our team of skilled engineers will work closely with you to understand your requirements, design the perfect keyboard mold, and ensure every detail is executed to the highest standards.

© 2026 Xiamen Gold Cattle. All rights reserved.

Specializing in precision injection molding for custom keyboard manufacturing and electronics production.