In the current fast – paced manufacturing landscape across the United States and Europe, the demand for high – quality aluminum CNC machining services is on the rise. As industries such as automotive, aerospace, and electronics continue to innovate, the need for precision – machined aluminum components has become more critical than ever. This is where Xiamen Goldcattle steps in, offering unparalleled expertise and services in aluminum CNC machining.

A Quarter – Century of Experience

With 25 years of dedicated experience in the field of CNC machining, Xiamen Goldcattle has amassed a wealth of knowledge and skills. Our journey over these two and a half decades has been a testament to our commitment to excellence. We have continuously adapted to industry advancements, staying at the forefront of CNC machining technology. This long – standing experience allows us to handle projects of varying complexities with ease, whether it’s a simple aluminum bracket or a highly intricate aerospace component.

State – of – the – Art Facilities

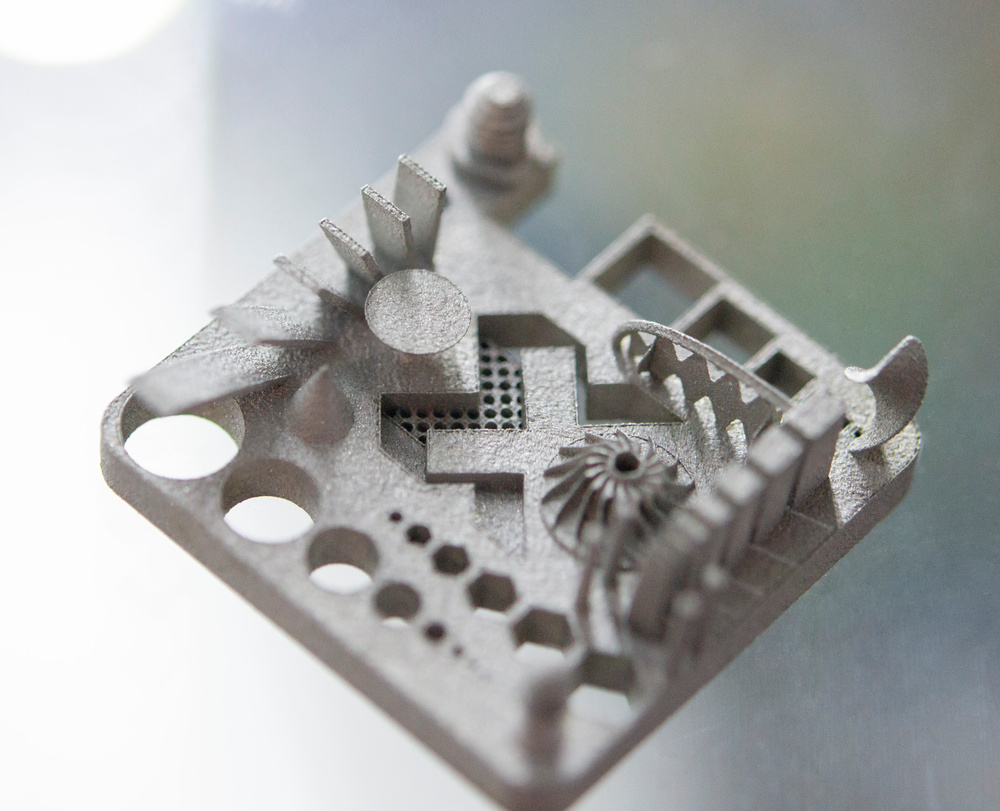

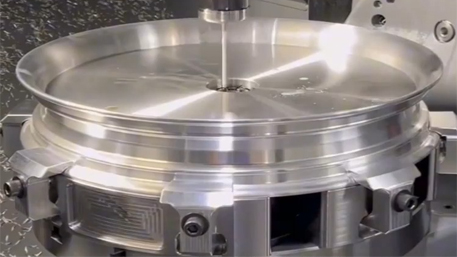

Our manufacturing facility is a key asset that sets us apart. Spanning over 1000 thousand square feet, it houses an impressive array of over a hundred machining devices. Among these, our advanced five – axis machining equipment stands out as a technological marvel.

The five – axis machines are capable of performing complex operations with extreme precision. They can move simultaneously along five axes (X, Y, Z, A, and B or C), enabling the creation of geometries that were previously difficult or impossible to achieve. This not only reduces the number of setups required but also significantly improves the accuracy and surface finish of the machined parts. For aluminum components, which often require high precision due to their use in sensitive applications, our five – axis machines are the ideal choice.

Aluminum Machining Expertise

Aluminum is a material that offers a unique combination of properties, such as high strength – to – weight ratio, excellent corrosion resistance, and good thermal conductivity. At Xiamen Goldcattle, we have mastered the art of machining aluminum to perfection.

Our team of highly skilled engineers and technicians understands the nuances of working with different aluminum alloys. Whether it’s 6061 aluminum, one of the most widely used alloys in the industry known for its strength and versatility, or 7075 aluminum, which is prized for its high strength in aerospace applications, we have the expertise to handle them all.

We use advanced cutting tools and optimized machining parameters to ensure that the aluminum parts we produce meet the highest standards of quality. Our machining processes are designed to minimize burrs, surface defects, and dimensional inaccuracies. For example, when machining aluminum components with tight tolerances, we rely on our precision measuring equipment, such as coordinate measuring machines (CMMs), to ensure that every part is within the specified tolerance range of ±[0.005] microns.

Customization for Every Need

We recognize that each project is unique, and that’s why our CNC machining service offers comprehensive customization options. Our team works closely with your design and engineering teams, whether you’re an automotive company looking for custom – designed engine parts or an electronics firm in need of precision – made enclosures.

Starting from the initial design phase, we use the latest CAD/CAM software to translate your ideas into actionable machining plans. Our engineers can provide valuable insights and suggestions to optimize the design for manufacturability, reducing costs without sacrificing quality. With our in – house programming capabilities, we can create highly customized CNC programs that are tailored to the specific requirements of your aluminum components.

Quality Assurance

Quality is non – negotiable at Xiamen Goldcattle. We have implemented a multi – stage quality control process to ensure that every aluminum part that leaves our facility is of the highest quality.

Our quality assurance team conducts thorough inspections at every stage of production, from the incoming raw materials to the final finished product. We source our aluminum materials from trusted suppliers and subject them to strict quality checks upon arrival. During the machining process, our operators monitor key parameters such as spindle speed, feed rate, and cutting force to ensure consistent quality.

After machining, our CMMs are used to verify the dimensional accuracy of the parts. We compare the measured dimensions with the original design specifications to ensure that any deviations are within the acceptable tolerance limits. In addition, we perform surface finish inspections to guarantee that the parts meet the required aesthetic and functional standards.

Competitive Pricing and Timely Delivery

We understand that cost and lead time are crucial factors for businesses in the United States and Europe. At Xiamen Goldcattle, we strive to offer competitive pricing without compromising on quality. Our large – scale operation, combined with our efficient production processes, allows us to optimize costs and pass on the savings to our customers.

In terms of delivery, we have a well – organized logistics system in place. We work with reliable shipping partners to ensure that your aluminum components are delivered to your doorstep.

Partner with Xiamen Goldcattle Today

Elevate your manufacturing strategy with a partner that combines 25 years of CNC mastery, cutting-edge technology, and unwavering dedication to quality.

Visit www.xmgoldcattle.com to upload your design, request a quote, or consult our engineers. Your precision, our passion.

Xiamen Goldcattle Industrial & Trade Co., Ltd.

ISO 9001:2008 Certified | 100% Quality Guarantee | Global Shipping

Contact: Charlie Que | Tel: +86-18150097490 | Email: charlie@plasticmetalparts.com