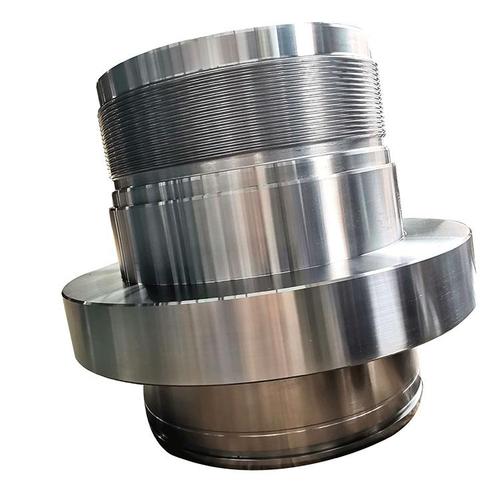

Laser engraving and custom CNC (Computer Numerical Control) machining are two important processing technologies in modern manufacturing. Laser engraving utilizes the high energy density of the laser beam for non-contact processing, which has the advantages of high precision, high efficiency and wide applicability. CNC customized machining, on the other hand, realizes precise machining of complex parts through computer-controlled machine tools.

1.Processing service flow

1.1 Demand communication

Customers are required to provide detailed design drawings or samples of the parts, clarifying key information such as material, size, precision requirements and machining volume.

We will have in-depth communication with the customer to confirm the processing requirements, answer questions, and give a preliminary machining program and quotation.

1.2 Process design

According to the customer’s requirements, our technicians will carry out the process design, including the selection of suitable laser engraving parameters (such as power, speed, frequency, etc.), CNC machine tool programming, tool selection and fixture design.

After the design is completed, the process design will be submitted to the customer for comments and necessary adjustments.

1.3 Material Preparation

According to the process design requirements, prepare raw materials that meet the standards and carry out the necessary pre-treatment (such as cutting, cleaning, drying, etc.).

Ensure that the quality of the material meets the processing requirements and avoid affecting the processing quality due to material problems.

1.4 Processing production

The prepared materials will be clamped on the CNC machine and processed according to the predetermined process design scheme.

During processing, technicians will monitor the processing status in real time and adjust the machine parameters to ensure processing accuracy and efficiency.

The laser engraving link will utilize the high energy density laser beam to engrave the material finely, realizing the precise presentation of patterns, text and other elements.

1.5 Quality Inspection

After processing is completed, strict quality inspection is carried out on the fittings, including dimensional measurement, shape and position tolerance checking, and surface quality assessment.

Ensure that the accessories meet the design requirements and customer standards, and rework or scrap the non-conforming products.

1.6 Delivery and after-sale

Pack the qualified accessories and deliver them according to the time and place required by customers.

Provide perfect after-sales service, including technical support, parts replacement and maintenance, etc. to ensure customer satisfaction.

2.Technical points

Optimization of laser engraving parameters

According to the characteristics of different materials, reasonably set the laser power, speed, frequency and other parameters to achieve the best engraving effect.

Pay attention to avoid over-burning, burning and other undesirable phenomena to ensure that the engraving surface is flat and clear.

CNC Machine Programming

Programming needs to consider the optimization of the machining path, reduce the empty stroke, improve processing efficiency.

Ensure that the tool path matches the contour of the workpiece to avoid overcutting or undercutting.

Fixture design

Design reasonable fixtures to ensure the stability and accuracy of the workpiece in the machining process.

The fixture should be easy to install and dismantle for quick replacement of the workpiece.

3.Equipment Requirements

CNC laser engraving machine: with high precision, high speed, high stability, can meet the needs of various complex patterns and text engraving.

Laser generator: stable performance, adjustable output power to ensure the consistency of the engraving effect.

Control system: with powerful programming and monitoring functions, it can adjust the processing parameters in real time to ensure the processing accuracy and efficiency.

Testing equipment: including size measuring instrument, microscope, etc., for quality testing of processed parts.

4.Quality control measures

Establish a perfect quality management system to monitor the whole process of processing.

Regular maintenance and repair of equipment to ensure that the equipment is in the best working condition.

Conduct regular training for technicians to improve the skill level and quality consciousness.

Implement a strict inspection system, sampling or full inspection of each batch of accessories to ensure product quality in line with customer requirements.

5.Laser engraving accessories application fields

Automobile manufacturing industry: in the automobile manufacturing industry, laser engraving accessories are widely used in parts and components of the logo, lettering and decoration. For example, the use of laser engraving technology can be realized in the engine, body structure, wheel hubs and other parts of the fine engraving and patterns, to improve product traceability and brand image.

Electronic product manufacturing: In the manufacturing process of electronic products, laser engraving accessories are used for the marking and lettering of circuit boards, chips, electronic components and other parts. This helps product traceability and quality management, while the non-contact characteristics of laser engraving also avoids damage to electronic components.

Hardware products industry: Hardware products industry needs to mark and engrave all kinds of metal products to facilitate management and after-sales service. Laser engraving accessories can efficiently engrave characters and patterns on steel, aluminum alloy, copper and other metal materials.

Customized Laser Engraving Accessories Service FAQ

Q: What is Customized Laser Engraving Accessories Service?

A: Customized laser engraved parts service refers to the processing service of customizing all kinds of mechanical parts for customers according to their specific needs by using laser engraving technology. This technology is used to accurately engrave on the surface of the material through a laser beam, realizing the fine presentation of patterns, text and other elements, and is widely used in many industrial fields.

Q: What are the main features of laser engraving technology?

A: The main features of laser engraving technology include:

High precision: the laser beam is capable of achieving micron-level engraving accuracy to meet the demands of precision processing.

Non-contact processing: the laser beam has no direct contact with the material surface during laser engraving, avoiding mechanical stress and deformation.

Wide applicability: almost any material can be engraved, including metal, non-metal, plastic, glass and so on.

High flexibility: able to quickly replace the engraving pattern and style, to adapt to the diversified production needs.

Energy saving and environmental protection: no need to use chemical reagents and cutting fluids in the laser engraving process, reducing environmental pollution and energy consumption.

Q: What is the process of customized laser engraving accessories service?

A: The process of customized laser engraving accessories service generally includes the following steps:

Demand communication: Communicate with customers in depth to understand the specific needs of the accessories, material, size, quantity and other information.

Design Confirmation: Provide the design scheme according to the customer’s needs, including engraving patterns, text and other content, and confirm with the customer without error.

Material Preparation: Select the material that meets the requirements and carry out the necessary pre-treatment, such as cutting and cleaning.

Laser engraving: put the prepared materials into the laser engraving machine and carry out accurate engraving according to the design scheme.

Quality inspection: carry out quality inspection on the finished engraved fittings to ensure that they meet customer requirements and quality standards.

Delivery and use: Deliver the qualified accessories to customers for use and provide necessary after-sales service support.