With the wave of intelligent manufacturing sweeping the world, CNC (Computer Numerical Control) machining technology is gradually becoming an important force to promote the transformation and upgrading of the manufacturing industry with its high precision, high efficiency and high flexibility. Online CNC machining service, as an emerging model in this field, is leading a new round of changes in the manufacturing industry with its unique advantages. This issue of Science and Technology Newspaper will discuss the status quo, advantages, challenges and future development trends of online CNC machining services.

1. Overview of online CNC machining services

1.1 Definition and Characteristics

Online CNC machining service refers to a service mode that efficiently connects CNC machining demand and machining capacity through the Internet platform. It breaks the geographical limitations of the traditional machining mode, and realizes the optimized allocation of machining resources and rapid response. At the same time, through digitalization and intelligent means, it improves machining accuracy and efficiency and reduces production costs.

1.2 Development history

In recent years, with the rapid development of cloud computing, big data, the Internet of Things and other technologies, as well as the increase in the demand for flexible and customized production in the manufacturing industry, online CNC machining services came into being and gradually matured. From the initial simple information matching, to today’s intelligent scheduling, remote monitoring, quality traceability and other functions of comprehensive coverage, online CNC machining services are gradually building an efficient, collaborative, intelligent ecosystem.

2. Advantages of online CNC machining services

2.1 Flexible and efficient

Online CNC machining services can quickly match suitable machining equipment and process solutions according to customer needs to achieve customized production. At the same time, the machining process is optimized through digital means to improve production efficiency and shorten the delivery cycle.

2.2 Cost Reduction

Through the platform operation, online CNC machining services can integrate scattered processing resources, form scale effects, and reduce unit processing costs. In addition, customers can also choose more cost-effective service solutions through platform price comparison.

2.3 Reliable quality

Online CNC machining services focus on quality control and traceability system construction, real-time monitoring and data analysis of the machining process through digital means to ensure that the processing quality meets customer requirements. At the same time, the platform also provides perfect after-sales service and warranty system to protect the rights and interests of customers.

3.Industry Case Study

Case 1: Online CNC machining service practice of an auto parts enterprise

The enterprise has realized rapid processing and customized production of complex auto parts by introducing online CNC machining service platform. The platform intelligently matches suitable machining equipment and process solutions according to the enterprise’s design drawings and processing requirements, and ensures processing quality through remote monitoring and data analysis. Eventually, the enterprise successfully shortened the production cycle by about 30% and reduced processing costs by about 20%.

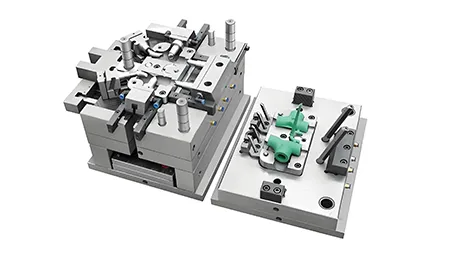

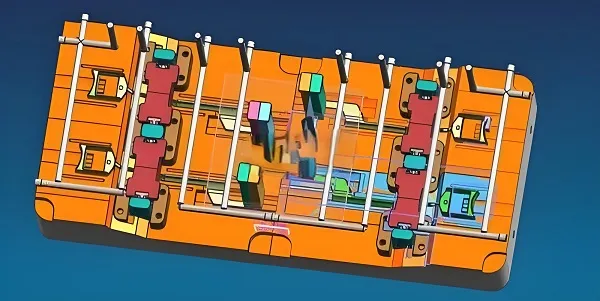

Case 2: A mold manufacturing enterprise’s digital upgrade road

The mold manufacturing enterprise realized the digital management of the whole chain from design to processing through the online CNC processing service platform. The platform not only provides high-precision CNC machining services, but also helps the enterprise establish a perfect digital design library and process database. Through data sharing and collaborative work, the enterprise has significantly improved the design efficiency and processing accuracy, and shortened the mold development cycle by about 40%.

4. Challenges and opportunities

4.1 Challenges:

Technical barriers: online CNC machining services involve the integration of technology and innovation in a number of fields, requiring companies to have strong technical strength and R & D capabilities.

Standardization problem: A unified system of standards and specifications has not yet been formed in the field of online CNC machining services, which affects the interoperability and comparability of services.

Market awareness: despite the many advantages of online CNC machining services, some enterprises and users still do not have a high degree of awareness, and need to increase publicity and promotion efforts.

4.2 Opportunities:

Policy support: with the implementation of the intelligent manufacturing strategy and the promotion of manufacturing transformation and upgrading, the government will increase its support for online CNC machining services and other emerging models.

Technological innovation: the rapid development of cloud computing, big data, artificial intelligence and other technologies provide a broader innovation space and application scenarios for online CNC machining services.

Market Demand: With the increasing demand for flexible and customized production in the manufacturing industry and the reconstruction and optimization of the global supply chain, online CNC machining services will usher in a broader market space and development opportunities.

5. Future Outlook

In the future, online CNC machining services will continue to be customer demand-oriented, and continuously improve service quality and efficiency through technological innovation and model innovation. At the same time, with the accelerated digital transformation and intelligent upgrading of the manufacturing industry, online CNC machining services will be deeply integrated with the industrial Internet, intelligent manufacturing and other fields to form a more complete service ecosystem. We have reason to believe that online CNC machining services will become one of the important forces to promote the high-quality development of the manufacturing industry.

6. Technological innovation and trends

6.1 Intelligent upgrade

With the continuous progress of Artificial Intelligence (AI) technology, online CNC machining services will move to a higher level of intelligence.AI algorithms will be able to automatically optimize the machining path, predict tool wear, adjust machining parameters, and even carry out fault warning and remote maintenance. This intelligent upgrade will further improve machining efficiency, reduce production costs, and enhance the reliability and stability of the overall service.

6.2 Internet of Things (IoT) integration

The wide application of IoT technology will bring a new change to online CNC machining services. Through IoT technology, machining equipment, raw materials, finished products and other links will be interconnected to form a complete digital supply chain. This will make the machining process more transparent and traceable, and also provide a richer data source for real-time monitoring and data analysis.

6.3 Cloud computing and big data applications

Cloud computing and big data technology provide powerful data processing and analysis capabilities for online CNC machining services. Through the cloud platform, machining data can be uploaded, stored and analyzed in real time, providing powerful support for enterprise decision-making. Big data analysis, on the other hand, can help enterprises identify bottlenecks and problems in the machining process, optimize resource allocation, and improve overall operational efficiency.

6.4 Virtual Reality (VR) and Augmented Reality (AR) Technology

VR and AR technology will bring a more intuitive and convenient user experience for online CNC machining services. Through VR technology, customers can virtually preview the machining effect, discover potential problems in advance and make adjustments. AR technology, on the other hand, can project the machining process into the real environment in real time, helping operators to carry out machining operations and equipment maintenance more accurately.

7. Talent training and education

With the rapid development of online CNC machining services, the demand for professionals is also growing. In order to cultivate more talents with knowledge and skills in the fields of CNC machining, programming, intelligent manufacturing, etc., it is necessary to strengthen cooperation with universities, vocational colleges and other educational institutions, and to jointly develop talent training programs and teaching plans. At the same time, it is also necessary to strengthen on-the-job training and continuing education to improve the professionalism and skill level of existing practitioners.

Conclusion

Online CNC machining service, as an important part of intelligent manufacturing, is leading a new round of change in the manufacturing industry with its unique advantages. Through technological innovation and model innovation, online CNC machining services will continue to improve service quality and efficiency to meet the manufacturing industry’s demand for flexible and customized production. In the future, with the continuous progress of technology and market expansion, online CNC machining services will usher in a broader development prospects and opportunities. We look forward to seeing more companies join in this field, and jointly promote the high-quality development of the manufacturing industry.