Motorcycle plays an important role in modern society as an easy, effective and flexible means of transportation. And the performance of a motorcycle depends largely on the quality and precision of its parts. In this article, we will introduce the use, advantages, specifications, customization process and common problems of CNC precision motorcycle parts in detail, and especially introduce the advantages of Xiamen Goldcattle in producing these products.

1. Usage of precision motorcycle parts

Precision motorcycle parts cover various key parts of a motorcycle, such as the engine assembly, transmission system, maneuvering system, electrical system and so on. Specifically, these parts include crankcase, cylinders, pistons, crankshafts, valves, camshafts, fuel tanks, filters, fuel pumps, oil pumps, carburetors, EFI systems, intake and exhaust systems, water tank fans, clutches, transmissions, frames, fenders, wheels, shock absorbers and so on. These parts not only affect the power performance of the motorcycle, but also relate to its safety, comfort and durability.

2. Advantages of precision motorcycle parts

High precision: CNC (Computer Numerical Control) machining technology ensures the high precision of the parts, which makes the fit between the parts closer and improves the overall performance of the motorcycle.

High Strength: The use of high quality materials, such as high strength steel and wear-resistant alloys, makes the parts have higher strength and wear resistance, and extends the service life of the motorcycle.

Lightweight: Under the premise of ensuring strength, the optimized design realizes the lightweight of the parts, which improves the fuel economy and handling of the motorcycle.

Customization: It can be personalized according to the specific needs of customers to meet the needs of different brands and models of motorcycles.

3.Precision motorcycle parts bearing specifications

The specifications of precision motorcycle parts vary according to the type and use of the parts. For example, the dimensions of bearings include inner diameter, outer diameter and width, which can be measured by vernier calipers, and suitable domestic bearings can be selected to replace them according to the measurement results. In addition, the dimensions of parts vary for different brands and models of motorcycles. Therefore, when customizing parts, customers are required to provide detailed information about the motorcycle brand, model and displacement to ensure that the customized parts can fit perfectly.

4.Customization process of precision motorcycle parts

Demand Confirmation: Communicate with customers to clarify the types, quantities, specifications and special requirements of the parts.

Design and Drawing: According to the customer’s needs, professional designers will carry out the design and drawing of the parts to ensure that each step meets the expected standards.

Material Selection: According to the specific use and requirements of the parts, select the appropriate materials, such as high-strength steel or wear-resistant alloys.

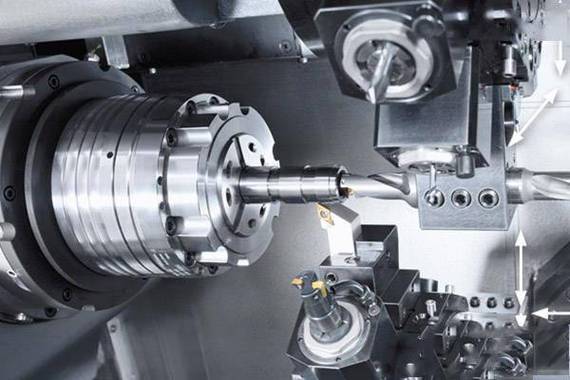

CNC machining: CNC machining technology is used for precision machining of the parts to ensure high accuracy and quality.

Quality Inspection: Strict dimensional inspection, performance test and appearance evaluation of the finished parts to ensure that the parts meet the customer’s requirements.

Packing and shipping: Pack the qualified parts and arrange for shipping.

5.Product customization

Material Selection: Customers can choose suitable materials according to their needs, but need to pay attention to the strength and wear resistance of the material to meet the requirements of use.

Dimensional accuracy: Since different brands and models of motorcycle parts have different dimensions, customers need to provide detailed dimensional information to ensure that the customized parts will fit perfectly.

Delivery time: The delivery time will be affected by many factors, such as the order quantity, material supply, processing difficulty, etc. Customers need to communicate with the manufacturer about the delivery time when customizing the parts in order to reasonably arrange their production schedule.

6.Xiamen Goldcattle Production Advantage

Xiamen Goldcattle Plastic & Metal Products Co., Ltd. has significant advantages in producing CNC precision motorcycle parts:

High-quality materials: Mold materials are made of S136, NAK80 and 718h for excellent durability and wear resistance.

High-precision machining: Advanced CNC machining technology is utilized to ensure high precision and quality of parts.

Customized service: Customized size options are available to meet specific requirements, ensuring a perfect fit for a wide range of motorcycle makes and models.

Quality Certification: Products comply with the international quality standard ISO 9001:2008 certification to ensure manufacturing reliability and consistency.

Professional Team: With professional designers and machining team, we are able to provide customers with one-stop service from design to machining.

To summarize, CNC precision motorcycle parts play an important role in improving the performance and prolonging the service life of motorcycles. And Xiamen Goldcattle has become the preferred partner of many motorcycle manufacturers and enthusiasts due to its advantages of high-quality materials, high-precision machining, customized service and professional team.