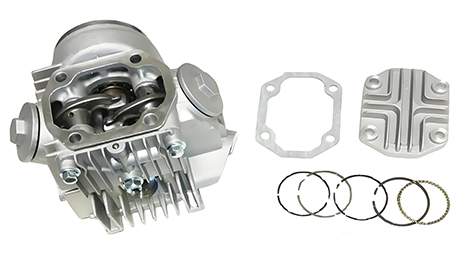

The motorcycle engine, serving as the “heart” of a motorcycle, directly determines its power, fuel efficiency, and operational stability. Engine parts, such as cylinders, pistons, crankshafts, and connecting rods, are the fundamental units that collectively ensure the engine’s efficient operation.

Xiamen Goldcattle, a leader in customized motorcycle engine parts, leverages its advanced Computer Numerical Control (CNC) machining technology, extensive industry experience, stringent quality control systems, and exceptional customer service to provide tailored engine part solutions for motorcycle manufacturers and enthusiasts worldwide. We focus on fulfilling our clients’ unique needs, refining every step from material selection, design optimization, to production processing to ensure that each product meets or exceeds expectations.

Purposes of Motorcycle Engine Parts

Motorcycle engine parts each have distinct roles in ensuring the engine’s efficient operation:

- Cylinder: Along with the piston, it forms the combustion chamber where fuel burns.

- Piston: It reciprocates within the cylinder, altering the combustion chamber’s volume to achieve fuel intake, compression, combustion, and exhaust.

- Crankshaft: Converts the piston’s reciprocating motion into rotational motion, outputting torque to propel the motorcycle forward.

- Connecting Rod: Connects the piston to the crankshaft, transmitting power.

Advantages of Motorcycle Engine Parts

- High Precision: Utilizing CNC machining technology ensures precise part dimensions, enhancing the engine’s overall performance.

- High Strength: Choosing premium materials and applying processes like heat treatment improves parts’ wear resistance and fatigue strength.

- Lightweight: Balancing strength with lightweight design reduces engine weight, boosting fuel efficiency.

- Corrosion Resistance: Special surface treatments, like zinc plating or chromium plating, enhance parts’ corrosion resistance, prolonging their lifespan.

Comparative Table of Motorcycle Engine Parts Performance Among Multiple Companies

| Company Name | Material | Precision (mm) | Strength (MPa) | Weight (kg) | Corrosion Resistance Rating |

|---|---|---|---|---|---|

| Xiamen Goldcattle | Aluminum Alloy | ±0.02 | 350 | 1.8 | Grade 9 |

| Company A | Cast Iron | ±0.05 | 400 | 3.0 | Grade 7 |

| Company B | Stainless Steel | ±0.03 | 280 | 2.5 | Grade 8 |

| Company C | Titanium Alloy | ±0.01 | 450 | 1.5 | Grade 10 |

Note: The above data are for reference only, and specific performances may vary based on product models and customization requirements.

Specifications and Dimensions of Motorcycle Engine Parts

Motorcycle engine parts’ specifications and dimensions vary based on the motorcycle model, engine type, and customer needs. Common cylinder diameters range from 50-100mm, piston strokes from 40-120mm, while crankshaft and connecting rod lengths depend on specific designs. Xiamen Goldcattle offers flexible customization services, accurately machining parts to meet requirements based on provided drawings or specific needs.

Customization Process for Motorcycle Engine Parts

- Needs Communication: Engage in thorough communication with clients to clarify specific part needs, purposes, and expected performance.

- Drawing Design: Design parts’ 3D models and 2D drawings based on client requirements, ensuring designs are reasonable and dimensions are precise.

- Material Selection: Choose materials based on the part’s operating environment and performance requirements.

- Process Formulation: Develop detailed machining processes, including CNC programming, tool selection, and cutting parameter settings.

- Production Machining: Use advanced CNC machining equipment to process parts strictly according to the process.

- Quality Inspection: Conduct rigorous size measurements, performance tests, and visual inspections on machined parts to ensure quality.

- Packaging and Shipment: Package qualified parts and ship them according to the client’s specified time and location.

Common Questions and Answers About Product Customization

-

Q: How are customized part prices calculated?

-

A: Prices primarily depend on material costs, processing difficulty, quantity, and customization level. We offer free quotation services, providing accurate quotes based on specific needs.

-

Q: What is the customization timeline?

-

A: The customization timeline varies based on part complexity and quantity, typically completed within 7-15 business days. For urgent needs, we offer expedited services.

-

Q: How do you ensure part quality?

-

A: We maintain a rigorous quality control system, overseeing every step from material procurement, production processing, to quality inspection. Additionally, we provide warranty services, ensuring clients have no worries during use.

Xiamen Goldcattle, with its superb craftsmanship, quality products, and attentive service, strives to become the leader in customized motorcycle engine parts globally. We look forward to collaborating with every client to create an even brighter future together.