In the realm of manufacturing, the choice between CNC (Computer Numerical Control) machining and manual machining can significantly impact the outcome of your project. Each method has its own set of characteristics, advantages, and limitations. This article aims to provide a comprehensive comparison of CNC machining and manual machining to help you make an informed decision for your specific needs. Understanding CNC Machining and Manual Machining

Understanding CNC Machining and Manual Machining

Understanding CNC Machining and Manual Machining

Understanding CNC Machining and Manual MachiningCNC Machining

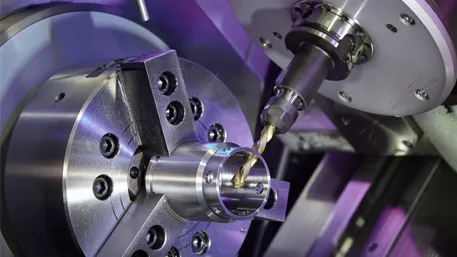

CNC machining is a highly automated manufacturing process. It relies on pre-programmed computer software to control the movement of machine tools such as lathes, mills, and routers. These programs precisely dictate the tool’s path, speed, and depth of cut, allowing for the creation of complex parts with a high degree of accuracy. Once the program is set up, the CNC machine can run continuously with minimal human intervention, making it suitable for both small and large production runs.

Manual Machining

Manual machining, on the other hand, requires direct human operation of the machine tools. An operator controls the movement of the cutting tool by hand, adjusting factors like feed rate, spindle speed, and depth of cut in real-time. This method demands a high level of skill and experience from the operator, as the quality of the final product depends heavily on their dexterity and knowledge.Precision and Accuracy

CNC Machining

CNC machining excels in terms of precision and accuracy. Computer-controlled systems can achieve extremely tight tolerances, often within thousandths of an inch. This makes it the go-to choice for industries where exact specifications are crucial, such as aerospace, medical device manufacturing, and high-precision automotive parts production. The consistent nature of CNC machining ensures that each part produced is virtually identical to the others, minimizing errors and waste.

Manual Machining

While skilled manual machinists can produce parts with good precision, it is generally more difficult to achieve the same level of accuracy as CNC machining. Human factors such as fatigue, reaction time, and slight variations in technique can introduce small errors. However, in the hands of a master craftsman, manual machining can still create parts that meet high-quality standards, although the process may be more time-consuming and less consistent across multiple parts.Production Efficiency

CNC Machining

CNC machining offers significant advantages in terms of production efficiency. Once the programming and setup are complete, the machine can run unattended for long periods, allowing for 24/7 production in many cases. This continuous operation reduces the overall production time for large quantities of parts. Additionally, CNC machines can perform multiple operations in a single setup, further streamlining the manufacturing process.

Manual Machining

Manual machining is typically slower compared to CNC machining. Each operation requires the operator’s full attention, and the process of making adjustments and changing tools can be time-consuming. As a result, manual machining is more suitable for small-scale production or custom jobs where the quantity of parts is limited.

Flexibility and Complexity

CNC Machining

CNC machining is highly flexible when it comes to producing complex parts. The ability to program intricate tool paths allows for the creation of parts with complex geometries, internal features, and contours. Changing the design of a part is relatively easy; it often only requires modifying the computer program. This makes CNC machining ideal for prototyping, where quick design iterations are common.

Manual Machining

Manual machining can also handle complex parts, but it requires a great deal of skill and experience. Creating complex shapes may involve multiple setups and a high level of manual dexterity. Modifying the design of a part during the machining process can be more challenging and may require starting over from scratch in some cases.

Cost

CNC Machining

The initial investment in CNC machining equipment is relatively high. CNC machines, along with the necessary programming software and training, can be expensive. However, for large production runs, the cost per part can be significantly reduced due to the high efficiency and low labor requirements. Additionally, the precision of CNC machining can minimize waste and rework, further saving costs in the long run.

Manual Machining

Manual machining generally requires less expensive equipment, making it a more affordable option for small businesses or hobbyists with limited budgets. However, the labor costs associated with manual machining can be substantial, especially for large production volumes. The higher potential for errors and rework can also add to the overall cost.

Skill Requirements

CNC Machining

CNC machining requires operators to have a good understanding of computer programming, machine operation, and basic machining principles. While training is available, it may take some time for operators to become proficient. However, once trained, CNC operators can manage multiple machines simultaneously, increasing productivity.

Manual Machining

Manual machining demands a high level of hands-on skill and experience. Manual machinists need to have