Answer

Industries requiring CNC machining include aerospace, automotive manufacturing, electronics, medical devices, mold making, energy, precision instruments, home appliances, jewelry, food packaging, military, shipbuilding, rail transportation, general machinery, etc.

Extended Response

I. Aerospace Industry

- Application Scenarios: Aircraft engine blades, fuselage frames, landing gear components, avionics housings.

- Reasons for Demand: Aerospace parts need high strength, lightweight design, and extreme environment resistance. CNC machining achieves high-precision forming of titanium alloys, aluminum alloys (tolerance ≤±0.01mm) and complex surfaces (e.g., aerodynamic shapes of turbine blades).

- Typical Case: 5-axis CNC machining of carbon fiber composite structures for Airbus A350 ensures aerodynamics and structural strength.

II. Automotive Manufacturing

- Application Scenarios: Engine blocks, transmission gears, brake system parts, new energy vehicle battery casings.

- Reasons for Demand: Auto parts require mass production and uniform precision. CNC enables high-speed cutting of cast iron, aluminum alloys (spindle speed >10,000rpm) and modular production (e.g., multi-process machining of engine blocks in one setup).

- Technical Edge: High-precision automotive molds (e.g., injection molds) reduce assembly errors and enhance vehicle performance.

III. Electronics Manufacturing

- Application Scenarios: Mobile phone mid-frames, computer heat sinks, chip packaging molds, connector terminals.

- Reasons for Demand: Electronics trend toward miniaturization (e.g., 0.1mm apertures) and precision. CNC handles micro-machining of stainless steel, copper alloys, achieving mirror finishes (Ra≤0.8μm) with high-speed spindles (20,000rpm+).

- Emerging Field: 5G base station heat sinks use CNC milling + deep-hole drilling to improve heat dissipation.

IV. Medical Equipment Industry

- Application Scenarios: Orthopedic implants (hip prostheses), surgical instruments, medical imaging device housings.

- Reasons for Demand: Medical products require biocompatibility. CNC enables fine engraving of titanium alloys, medical stainless steel (e.g., bionic textures on prostheses) and precision (e.g., syringe mold tolerance ≤±0.005mm) for sterile environments.

- Technical Case: 3D printing combined with CNC post-processing refines personalized orthopedic implants.

V. Mold Manufacturing

- Application Scenarios: Injection molds, die-casting molds, punch mold cores and frames.

- Reasons for Demand: Molds endure high pressure and friction. CNC machines hardened tool steel, carbide (HRC60+) and uses EDM + 5-axis milling for complex cavities (e.g., car bumper molds), ensuring 1M+ cycle life.

VI. Energy Industry

- Application Scenarios: Wind turbine gearbox parts, oil drilling bits, nuclear power plant valve components.

- Reasons for Demand: Energy equipment needs high pressure and corrosion resistance. CNC processes nickel-based alloys, titanium alloys, e.g., deep-hole boring for oil pipeline joints (depth-diameter ratio >50:1) to ensure sealing.

VII. Precision Instruments

- Application Scenarios: Optical lens brackets, sensor housings, high-end watch parts.

- Reasons for Demand: Instruments require micron-level precision (e.g., gyro frame tolerance ≤±0.002mm). CNC achieves mirror finishes on aluminum alloys, brass via temperature-controlled workshops and precision grating scales.

VIII. Home Appliance Manufacturing

- Application Scenarios: Refrigerator compressor housings, air conditioner impellers, high-end kitchenware handles.

- Reasons for Demand: Home appliance parts balance aesthetics and function. CNC performs high-gloss cutting on aluminum alloys, stainless steel (Ra≤0.4μm), e.g., one-step milling of premium oven cavities to reduce welding.

IX. Jewelry Industry

- Application Scenarios: Precious metal jewelry (rings, necklaces), gemstone setting bases.

- Reasons for Demand: Jewelry requires complex patterns and personalization. CNC engravers achieve 0.05mm-level precision on gold, platinum (e.g., micro-pavé diamond tracks) with CAD/CAM for mass customization.

X. Food Packaging Industry

- Application Scenarios: Food molds (chocolate forming), packaging machinery parts (sealing rollers).

- Reasons for Demand: Packaging equipment needs food-grade hygiene. CNC polishes 304 stainless steel to mirror finishes (Ra≤0.2μm) to prevent food residue and ensure mold wear resistance (e.g., 100,000+ uses for cookie molds).

XI. Military Industry

- Application Scenarios: Firearm components, missile casings, radar antenna frames.

- Reasons for Demand: Military products require high reliability and confidentiality. CNC processes tungsten steel, bulletproof ceramics, uses 5-axis machining for complex molds (e.g., shell fuze parts) to ensure performance in extreme conditions.

XII. Shipbuilding Industry

- Application Scenarios: Marine diesel engine parts, propellers, navigation equipment housings.

- Reasons for Demand: Marine parts need seawater corrosion resistance. CNC machines bronze, titanium alloys for large components (e.g., 5m-diameter propeller milling), optimizing blade hydrodynamics via 5-axis machines.

XIII. Rail Transportation

- Application Scenarios: High-speed rail gearboxes, train braking system parts, track connectors.

- Reasons for Demand: Rail parts withstand high loads and vibrations. CNC performs heavy cutting on high-manganese steel, ductile iron (cutting volume 1000cm³/min), e.g., precision turning of high-speed rail wheel axles for safety.

XIV. General Machinery Industry

- Application Scenarios: Pump bodies, valves, reducer housings.

- Reasons for Demand: General machinery requires standardized production. CNC uses batch program calling (e.g., G-code macros) for quick switching between part types, e.g., die-casting mold machining for water pump impellers balancing efficiency and precision.

XV. Emerging Fields

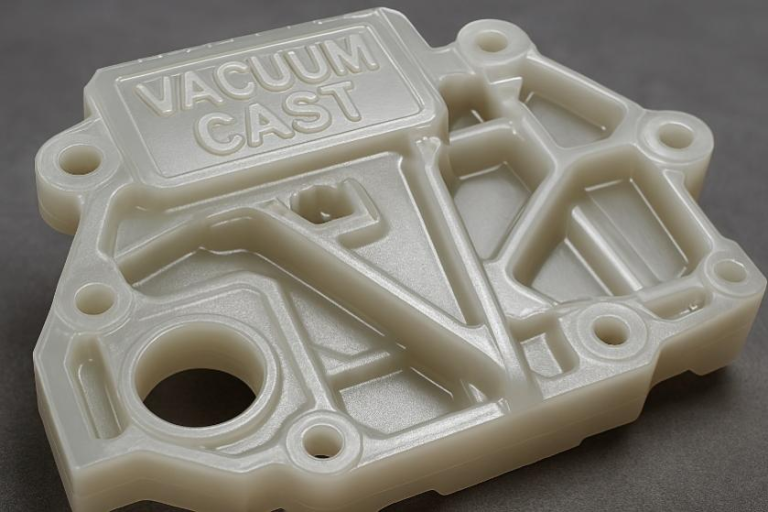

- 3D Printing Post-Processing: CNC milling and polishing to refine surface precision of metal 3D printed parts.

- Medical Device R&D: Rapid prototyping for low-volume trials of minimally invasive surgical instruments.

- Semiconductor Equipment: Machining core components like lithography precision guides and wafer carriers.

Conclusion

CNC machining serves as the core technology in modern manufacturing due to its high precision, efficiency, and material adaptability (metals, plastics, ceramics, etc.). From aerospace to consumer goods, it covers almost all industries requiring precision parts, especially for complex structures, tight tolerances, and mass production. With smart manufacturing advancements, integrating CNC with industrial robots and IoT will further expand its applications.