I. Definition of CNC Metal Part Polishing

CNC metal part polishing is a processing technique that uses Computer Numerical Control (CNC) technology to finely treat the surface of metal parts. By controlling the movement trajectory and parameters of the polishing equipment, and using polishing tools such as polishing wheels, polishing belts, and polishing pastes, it cuts, grinds, and polishes the surface of metal parts. This process reduces surface roughness, improves surface finish and aesthetics, and also enhances the surface properties of the parts, such as reducing the coefficient of friction and enhancing corrosion resistance. Compared with traditional manual polishing, CNC metal part polishing offers higher precision, consistency, and production efficiency, meeting the strict requirements for the surface quality of metal parts in modern manufacturing.

II. Key Points of CNC Metal Part Polishing Technology

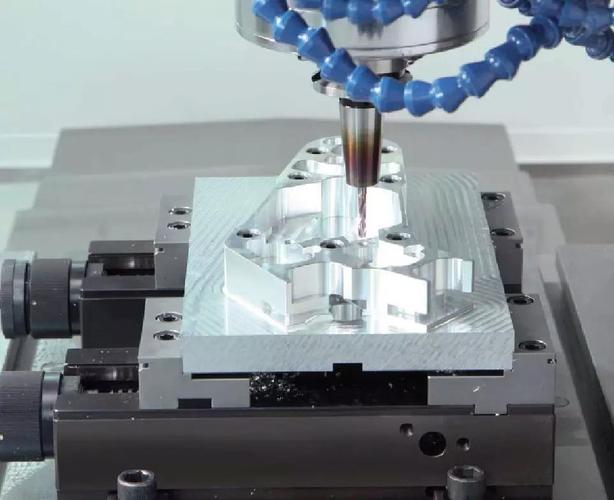

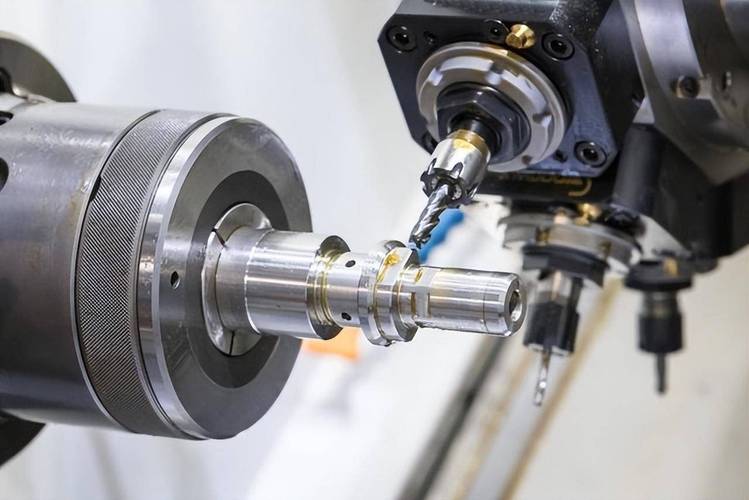

Selection of Polishing Equipment and Tools

Based on the shape, size, and polishing requirements of the parts, appropriate CNC polishing equipment is chosen, such as five – axis polishing machines, planar polishing machines, etc. At the same time, for different metal materials and polishing stages, polishing tools are rationally selected. For example, in the rough – polishing stage, a coarser – grit polishing paste and a hard polishing wheel can be used to quickly remove surface machining marks. In the fine – polishing stage, a fine – grit polishing paste and a soft polishing cloth wheel are used to achieve a mirror – like finish.

Setting of Process Parameters

This includes polishing pressure, polishing speed, and polishing time. Excessive polishing pressure may cause surface deformation or scratching of the parts, while too little pressure results in low polishing efficiency. The polishing speed needs to match the polishing pressure and the hardness of the material. Generally, for metals with higher hardness, the speed should be reduced. The polishing time is determined according to the surface quality requirements to ensure the desired finish is achieved.

Path Planning and Programming

Use CAD/CAM software to create a 3D model of the part. According to the surface shape of the part and the polishing requirements, a reasonable polishing path is planned. Through programming, the polishing tool moves along the preset path to avoid repeated polishing or missed areas, ensuring the uniformity of the polishing effect. For parts with complex curved surfaces, special path – planning algorithms are required to ensure good contact between the polishing tool and the part surface.

III. CNC Metal Part Polishing Processing Flow

Part Pretreatment

Clean the metal part to remove surface oil, impurities, and oxide scale. Methods such as ultrasonic cleaning and chemical cleaning can be used. If there are significant machining errors or defects on the part surface, pretreatment processes such as grinding and lapping are carried out first to make the surface flatness meet certain requirements, preparing for subsequent polishing.

Clamping and Tool Setting

Fix the part on the worktable of the CNC polishing equipment using a special fixture to ensure firm clamping and accurate positioning. Then, perform tool – setting operations to determine the relative position between the polishing tool and the part, and establish the workpiece coordinate system to ensure the accuracy of the polishing process.

Programming and Debugging

Write the planned polishing path and process parameters into a numerical control program and input it into the control system of the polishing equipment. Before formal processing, conduct trial – processing and debugging to check whether the polishing path is reasonable, the process parameters are appropriate, and observe the polishing effect. Adjust the program and parameters in a timely manner if there are any problems.

Polishing Processing

Start the CNC polishing equipment and carry out polishing processing according to the program instructions. During the processing, monitor the polishing status in real – time, such as polishing pressure, temperature, and sound. If any abnormalities are found, stop the machine in time to prevent part damage or equipment failure.

Quality Inspection and Post – treatment

After processing, use inspection equipment such as roughness testers and gloss meters to detect the surface roughness, gloss, and other indicators of the part to ensure they meet the design requirements. If not, analyze the reasons and carry out re – polishing. After passing the inspection, carry out post – treatment such as cleaning and drying the part to remove the remaining polishing paste and impurities on the surface.

IV. Processable Materials for CNC Metal Part Polishing

Ferrous Metals

This includes carbon steel, alloy steel, and stainless steel. Carbon steel and alloy steel are often used to manufacture machine parts, molds, etc. Polishing can improve their surface wear resistance and aesthetics. Stainless steel, due to its good corrosion resistance and aesthetics, is widely used in fields such as kitchenware, medical devices, and decorative projects. After polishing, the surface of stainless steel is mirror – smooth, more ornamental, and practical.

Non – ferrous Metals

Such as aluminum alloys, copper alloys, and magnesium alloys. Aluminum alloys, with their low weight and high strength, are widely used in the aerospace, automotive manufacturing, and electronics industries. Polishing can enhance their surface texture and corrosion resistance. Copper alloys have good electrical and thermal conductivity and are often used to manufacture electrical components and decorations. After polishing, the surface of copper alloys shows a unique metallic luster. Magnesium alloys, with their low density, are ideal lightweight materials. Polishing can improve their surface properties and expand their application range.

V. Characteristics of CNC – Polished Metal Parts

High Surface Finish

The surface roughness of metal parts polished by CNC can be reduced to below Ra0.01μm, achieving a mirror – like effect, which significantly improves the appearance quality of the parts and meets the strict appearance requirements of high – end products.

Good Dimensional Accuracy

While improving the surface finish, CNC polishing can ensure the dimensional accuracy of the parts, avoiding dimensional deviations caused by polishing and ensuring the assembly accuracy of the parts with other components.

Improved Surface Properties

The surface of polished metal parts becomes denser, effectively reducing the coefficient of friction and wear. At the same time, the smooth surface is less likely to adhere to impurities and corrosive media, enhancing the corrosion and oxidation resistance of the parts and extending their service life.

Good Consistency

Due to the use of numerical control technology, CNC metal part polishing can ensure a high degree of consistency in the surface quality of parts produced in large quantities, avoiding quality differences caused by human factors in manual polishing.

VI. Application Fields of CNC Metal Part Polishing

Electronics and Electrical Appliances Field

The metal casings of mobile phones, tablets, laptops, and other electronic products can obtain an exquisite appearance and good hand – feel through the CNC polishing process, enhancing the market competitiveness of the products. In addition, for metal pins and connectors of electronic components, polishing can reduce contact resistance and improve electrical performance.

Automotive Manufacturing Field

Automotive wheels, decorative strips, and interior metal parts, after polishing, are not only beautiful but also have enhanced corrosion resistance. In the engine and transmission systems, some precision metal parts, after polishing, can reduce friction, improve mechanical efficiency, and reduce energy loss.

Aerospace Field

Metal parts such as aero – engine blades and aircraft structural parts have extremely high requirements for surface quality. CNC polishing can reduce surface roughness, decrease air resistance, and improve engine efficiency. At the same time, it can improve the fatigue resistance of the parts, ensuring the safety and reliability of aerospace equipment.

Mold Manufacturing Field

The surface quality of plastic molds and die – casting molds directly affects the quality of the molded products. Through CNC polishing, the surface roughness of the mold can be reduced, making demolding smoother, reducing surface defects of the products, and improving the service life and production efficiency of the mold.

Jewelry Field

Precious metal jewelry such as gold, silver, and platinum, after CNC polishing, can show a brilliant luster and delicate texture, enhancing the artistic and commercial value of the jewelry.

VII. Technical Description of CNC Metal Part Polishing

CNC metal part polishing technology is an essential process in modern manufacturing, integrating knowledge from multiple disciplines such as numerical control technology, materials science, and machining. Compared with traditional polishing techniques, CNC polishing has significant advantages such as high automation, high processing precision, high production efficiency, and stable quality, meeting the diverse needs of different industries for the surface quality of metal parts.

With the development of the manufacturing industry towards high – end and precision, CNC metal part polishing technology is also constantly innovating. On the one hand, the research and development of new polishing materials and tools, such as nano – grade polishing pastes and high – performance polishing wheels, can further improve polishing efficiency and surface quality. On the other hand, intelligent polishing technology is gradually emerging. By introducing sensors and artificial intelligence algorithms, real – time monitoring and automatic adjustment of the polishing process are realized, improving the level of intelligent processing. In the future, CNC metal part polishing technology will continue to develop in the directions of high precision, high efficiency, environmental friendliness, and intelligence, providing strong support for the high – quality development of the manufacturing industry.

The above comprehensively interprets CNC metal part polishing. If you want to know specific cases or have in – depth discussion needs on a certain link, you can talk to me at any time.