- Preparatory Work (Mold/Resin Selection + Environment Control)

- Mold Pre-Treatment (Cleaning + Sealing + Release Agent Application)

- Resin Preparation (Mixing + Coloring + Additive Integration)

- Defoaming (Critical for Surface Quality)

- Resin Pouring (Flow Control + Cavity Filling)

- Curing (Temperature/Time Regulation)

- Demolding & Post-Processing

Step 1: Preparatory Work (Lay the Groundwork for Success)

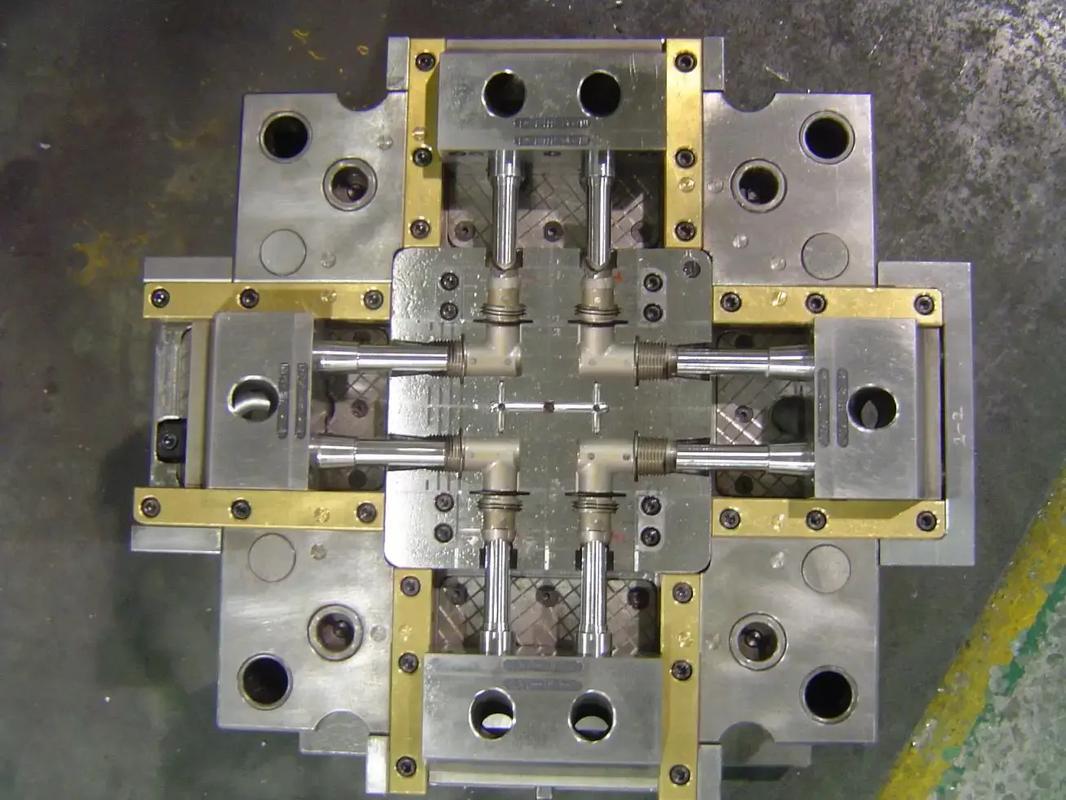

A. Mold Selection (Match to Resin & Application)

|

Mold Material

|

Resin Compatibility

|

Detail Precision

|

Reusability

|

Best For

|

|

Silicone (Platinum-Cure)

|

Epoxy, Polyurethane, Unsaturated Polyester

|

High (captures 0.1mm fine details)

|

50–200 cycles

|

Small-batch crafts (coasters, jewelry), model replicas (1:24 car parts)

|

|

Silicone (Tin-Cure)

|

Polyurethane, Unsaturated Polyester

|

Medium (0.2–0.5mm details)

|

20–50 cycles

|

Low-cost prototypes, disposable parts

|

|

Metal (Aluminum/Steel)

|

High-temperature epoxy (≥80℃ curing)

|

High (0.05mm details)

|

1000+ cycles

|

Industrial parts (gaskets, electrical insulators), high-volume production

|

|

Plastic (ABS/PET)

|

Low-viscosity epoxy (<500 cP)

|

Medium (0.3–0.8mm details)

|

10–30 cycles

|

Simple parts (trinkets, keychains), one-off prototypes

|

B. Resin Selection (Based on Strength & Use Case)

|

Resin Type

|

Viscosity (25℃)

|

Curing Time (25℃)

|

Final Hardness

|

Best For

|

|

Epoxy Resin

|

300–800 cP

|

24–48 hours

|

邵氏 D 80–90 (rigid)

|

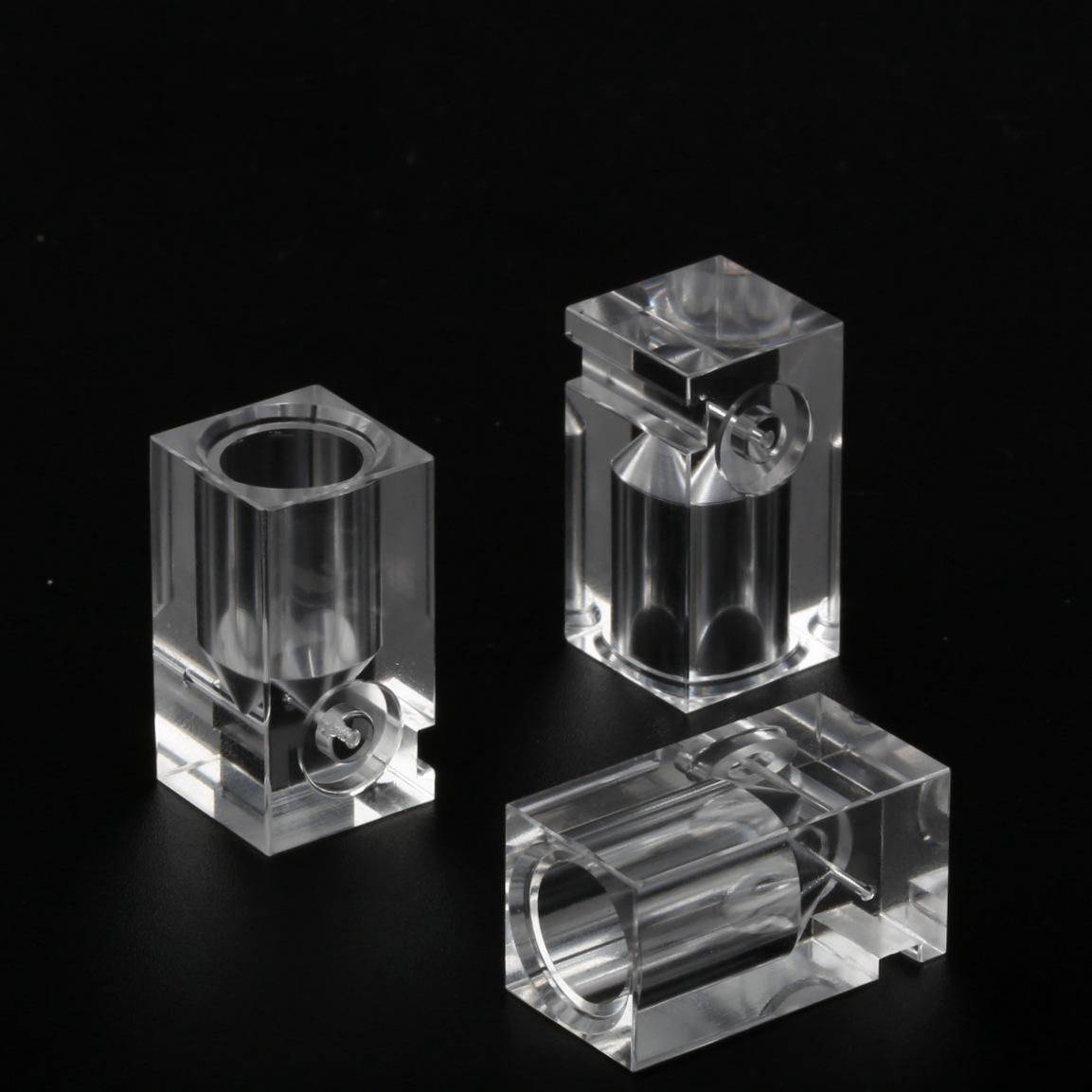

High-strength parts (coasters, industrial insulators), transparent products (crystal crafts)

|

|

Polyurethane Resin

|

100–500 cP

|

4–24 hours

|

邵氏 A 50–90 (flexible to rigid)

|

Flexible parts (gaskets, toy components), rubber-like replicas

|

|

Unsaturated Polyester Resin

|

200–600 cP

|

1–6 hours

|

邵氏 D 70–85 (semi-rigid)

|

Low-cost crafts (fiberglass parts, figurines), large-volume production

|

C. Environment Control (Stability = Quality)

- Temperature: 20–25℃ (±2℃) — too cold (<18℃) slows curing; too hot (>30℃) causes rapid exotherm (resin overheats, cracks).

- Humidity: <60% RH — high humidity (>70%) leads to surface “blooming” (white, cloudy film) on epoxy resin.

- Dust Control: Work in a cleanroom or cover the area with a dust sheet—dust particles (≥5μm) create visible blemishes on the part surface.

D. Tools Preparation

- Mixing Tools: Disposable plastic cups (100–500ml), wooden stir sticks (or electric mixers with low-speed setting: 300–500 RPM), electronic scale (precision ±0.1g—critical for resin proportioning).

- Pouring Tools: Funnel (for narrow mold cavities), pipettes (for small-volume filling, e.g., <5ml), silicone spatula (to scrape residual resin from cups).

- Defoaming Tools: Vacuum chamber (for industrial use, 5–10L capacity), heat gun (low-temperature grade: 50–80℃), toothpicks (for surface bubble popping).

Step 2: Mold Pre-Treatment (Prevent Leaks & Ensure Easy Demolding)

Key Tasks:

- Mold Cleaning:

-

- Wipe silicone/metal molds with isopropyl alcohol (70–90% concentration) to remove dust, oil, or residual resin from previous use.

-

- For deep-cavity molds (e.g., model car bodies), use compressed air (0.3–0.5 MPa) to blow out hidden debris.

-

- Critical: Ensure molds are fully dry (alcohol evaporates in 5–10 minutes) — moisture causes resin bubbles.

- Sealing Leaks:

-

- Inspect mold seams (especially silicone molds) for gaps (>0.1mm). Seal with high-temperature tape (e.g., 3M Kapton tape) or silicone sealant (cure for 24 hours before use).

-

- For two-piece molds (e.g., metal molds), apply a thin layer of mold clamp grease to the mating surface—prevents resin from seeping between halves.

- Release Agent Application (When Needed):

-

- Silicone Molds: Usually not required (silicone’s non-stick property), but for complex parts with undercuts, apply a light coat of silicone release spray (e.g., Mold Release 200) — let dry for 10–15 minutes.

-

- Metal/Plastic Molds: Mandatory—use a wax-based release agent (for epoxy) or PTFE-based spray (for polyurethane). Apply 2–3 thin coats (allow 5 minutes between coats) to avoid resin sticking.

Common Mistake:

Step 3: Resin Preparation (Mixing Is Make-or-Break)

Key Tasks:

- Resin & Hardener Ratio:

-

- Use an electronic scale (not volume measurement) to weigh resin (Part A) and hardener (Part B). Common ratios:

-

-

- Epoxy: 1:1 or 2:1 (by weight—check manufacturer specs, e.g., ArtResin 1:1, West System 2:1).

-

-

-

- Polyurethane: 1:1 or 10:1 (e.g., Smooth-On Ecoflex 1:1, Castaldo polyurethane 10:1).

-

-

- Example: For 100g of epoxy resin (1:1 ratio), weigh 50g Part A + 50g Part B.

- Mixing Process:

-

- Pour Part A into a clean cup first, then add Part B (avoids hardener residue in the cup).

-

- Stir slowly (300–500 RPM if using an electric mixer) for 3–5 minutes—scrape the cup bottom and sides to ensure no unmixed resin remains (unmixed resin causes soft spots in the cured part).

-

- Avoid rapid stirring—this introduces air bubbles (we’ll fix this in Step 4, but minimizing bubbles here saves time).

- Adding Color/Additives:

-

- Coloring: Add resin dye (0.5–2% of total resin weight, e.g., alcohol-based dye for epoxy) after mixing Part A and B. Stir for 1–2 minutes until uniform—too much dye weakens the resin.

-

- Fillers: For strength (e.g., industrial parts), add glass fiber (5–15% by weight) or talc (10–20%)—mix at low speed to avoid clumping.

-

- Glitter/Inlays: Add decorative elements (e.g., glitter, dried flowers) after defoaming (Step 4) to prevent them from sinking.

Critical Check:

Step 4: Defoaming (Eliminate Bubbles for Perfect Surfaces)

A. Static Defoaming (For Small Batches/Crafts)

- Process: Let mixed resin sit in a cup for 5–10 minutes at 20–25℃. Bubbles rise to the surface due to buoyancy.

- Tips: Tap the cup gently (2–3 times) on a hard surface—releases trapped air from the cup bottom. Pop surface bubbles with a toothpick or heat gun (low 档,15–20cm distance).

B. Vacuum Defoaming (For Industrial/High-Precision Parts)

- Equipment: Tabletop vacuum chamber (5–10L, e.g., BestEquip 5L Vacuum Degassing Chamber) with a vacuum pump (0.5 HP, capable of -0.095 MPa).

- Process:

-

- Pour mixed resin into a vacuum-safe cup (fill to 1/3 capacity—resin expands when vacuumed).

-

- Place the cup in the chamber, close the lid, and turn on the pump.

-

- Maintain -0.095 MPa for 2–3 minutes—bubbles expand and burst (resin may foam, but it settles as air is removed).

-

- Release the vacuum slowly (over 30 seconds)—prevents resin from splashing.

C. Heat-Assisted Defoaming (For Viscous Resins)

- Use Case: Resins with high viscosity (>800 cP, e.g., some epoxy blends) that trap bubbles.

- Process: Heat the mixed resin to 30–35℃ (using a water bath or heat mat) before defoaming—lowers viscosity, making bubbles easier to release.

Common Mistake:

Step 5: Resin Pouring (Control Flow to Avoid Air Traps)

Key Tasks:

- Mold Positioning:

-

- Place the mold on a level surface (use a spirit level to confirm—±0.5° deviation causes uneven resin distribution).

-

- For complex molds with deep cavities (e.g., model engine parts), tilt the mold at 15–30°—lets resin flow into narrow gaps first.

- Pouring Method:

-

- Slow Pour: Tilt the resin cup and pour along the mold’s edge (not directly into the cavity) at a speed of 5–10ml/s. This avoids splashing (which introduces bubbles) and lets air escape ahead of the resin.

- flame diversion troughUse: For molds with small openings (e.g., jewelry molds), insert a small funnel or plastic tube into the cavity—guides resin to the bottom, preventing air traps.

- Layered Pouring (For Thick Parts): If the part is >10mm thick (e.g., a resin tabletop), pour in 2–3 layers (each 3–5mm thick) with 1–2 hours of curing between layers. This prevents excessive exotherm (thick resin overheats and cracks).

- Cavity Filling:

-

- Fill the mold to 1–2mm above the desired part height—resin shrinks 1–3% during curing (check manufacturer specs: epoxy shrinks ~1.5%, polyurethane ~2.5%).

-

- After pouring, tap the mold gently (2–3 times) on the surface—releases air trapped in corners or undercuts.

Critical Check:

Step 6: Curing (Regulate Temperature & Time for Full Hardness)

Key Parameters by Resin Type:

|

Resin Type

|

Curing Temperature

|

Full Cure Time

|

Post-Curing (Optional)

|

|

Epoxy

|

20–25℃ (room temp)

|

24–48 hours

|

60–80℃ for 2–4 hours (boosts hardness by 10–15%)

|

|

Polyurethane

|

20–25℃

|

4–24 hours

|

Not recommended (may cause discoloration)

|

|

Unsaturated Polyester

|

20–25℃

|

1–6 hours

|

40–50℃ for 1 hour (reduces residual odor)

|

Curing Best Practices:

- Avoid Disturbance: Do not move or touch the mold during curing—even slight movement causes surface ripples.

- Exotherm Control: For large parts (>500ml resin volume), place the mold in a water bath (20–22℃) to dissipate heat—prevents overheating (epoxy can reach 80℃+ in large batches, causing cracking).

- Cure Check: After the recommended time, press the resin surface gently with a gloved finger—no indentation or stickiness means full curing.

Common Mistake:

Step 7: Demolding & Post-Processing (Finish to Specification)

A. Demolding:

- Silicone Molds:

-

- Gently stretch the mold from the edges (avoid pulling the part directly).

-

- For complex parts with undercuts, peel the mold in small sections (e.g., start with the part’s least detailed area) to avoid tearing.

- Metal/Plastic Molds:

-

- Remove clamps (if using two-piece molds) and separate the mold halves using a plastic pry tool (avoids scratching the part).

-

- For tight-fitting parts, tap the mold lightly with a rubber mallet—loosens the part without damage.

B. Post-Processing:

- Trimming: Use a utility knife (for soft resin) or a CNC router (for rigid epoxy) to remove excess resin (flash) from mold seams.

- Sanding: Sand the part with abrasive paper (400–2000 grit) to smooth rough edges—start with 400 grit for flash removal, then 1200–2000 grit for a polished finish.

- Polishing: For transparent parts (e.g., epoxy coasters), use a polishing compound (e.g., Turtle Wax) and a buffing wheel (1500 RPM) to achieve a mirror finish.

- Repair: Fill small scratches or bubbles with a thin layer of resin (mixed at 1:1 ratio) and cure for 2–4 hours.

Critical Check:

Key Quality Control (QC) Nodes (Must Not Skip)

- After Mixing: Check resin for uniformity (no streaks) — unmixed resin = soft spots.

- After Defoaming: Inspect resin under bright light—no visible bubbles (>0.1mm) for high-precision parts.

- After Curing: Test hardness with a Shore hardness tester (epoxy ≥80D, polyurethane ≥70A).

- After Post-Processing: Use a caliper to check dimensions—tolerance should be ±0.1mm for industrial parts, ±0.5mm for crafts.

Application-Specific Tips

- Transparent Parts (e.g., Resin Art):

-

- Use high-transparency epoxy (e.g., Clear Cast Epoxy) and avoid dust during curing—cover the mold with a glass plate.

-

- Polish with 2000–5000 grit sandpaper before buffing for maximum clarity.

- Industrial Parts (e.g., Electrical Insulators):

-

- Use flame-retardant epoxy (UL94 V0 rated) and post-cure at 80℃ for 4 hours to boost heat resistance.

-

- Test for electrical insulation (use a megohmmeter—resistance ≥10¹² Ω).

- Flexible Parts (e.g., Toy Wheels):

-

- Choose polyurethane resin with 邵氏 A 50–70 hardness and avoid post-curing (preserves flexibility).

Final Takeaway

- Matching mold/resin to your application (silicone for crafts, metal for industrial parts).

- Controlling bubbles (vacuum defoaming for high requirement,static defoaming for small batches).

- Following curing times/temperatures (never rush demolding).