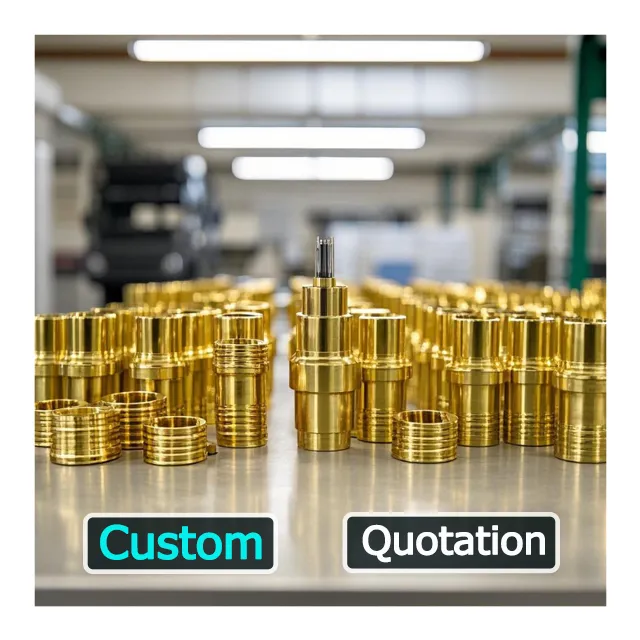

Exclusive customized solutions for special-shaped automotive parts

Place of Origin: Fujian, China

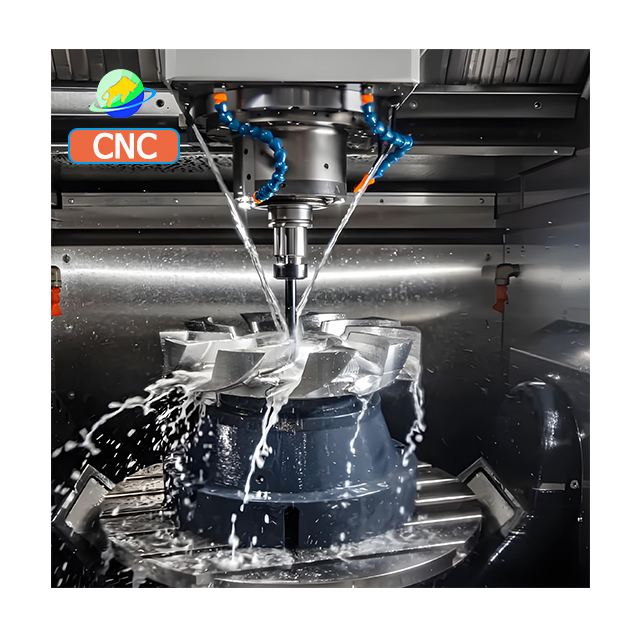

Type: Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping

Micro Machining or Not: Micro Machining

Model Number: CMP-06

Brand Name: JSD

Product name: Automotive Stainless Steel Accessories

Material: Stainless Steel

Tolerance: +/- 0.005mm

QC: 100% inspection before delivery

Service: OEM

Surface Treatment: anodizing, sandblasting, metal plating, polishing, brushing etc.

Machinable accessory types: All

Packaging Details: Carton, wooden box, or depend on customer requested

Certification: ISO 9001

Application: Car