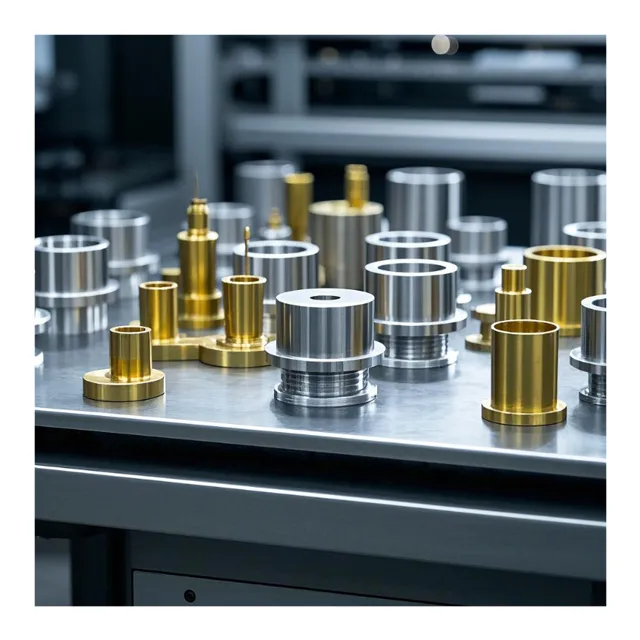

Custom CNC machined anodized aluminum parts

Place of Origin: Fujian, China

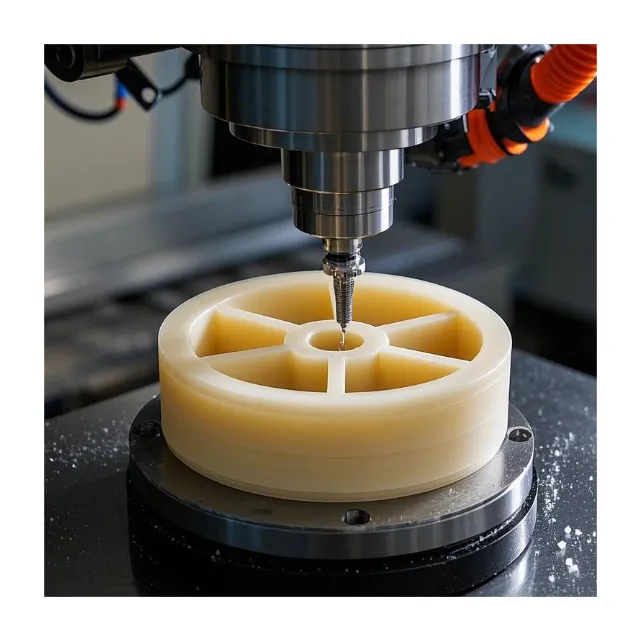

Type: Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping

Micro Machining or Not: Micro Machining

Model Number: CMP-15

Brand Name: JSD

Product name: anodized aluminum parts

Material: Aluminum Alloy

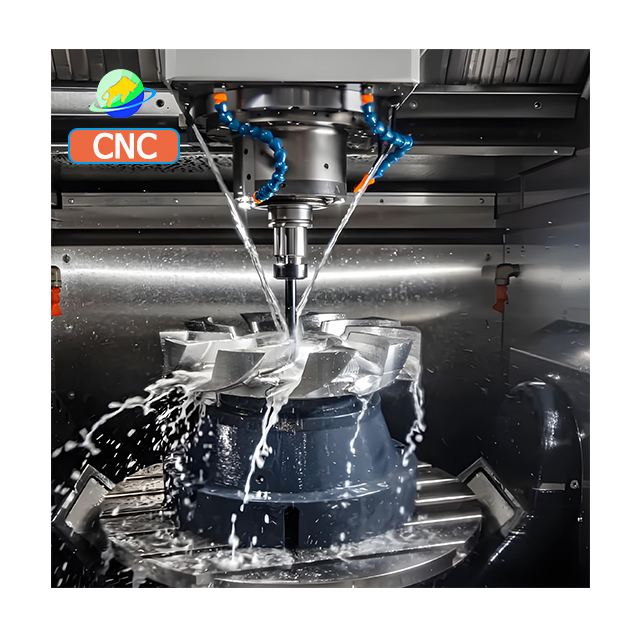

Process: CNC Turning Milling

Surface treatment: Customer’s Request

Color: Customized Color

OEM/ODM: OEM ODM CNC Milling Machining Service

Logo: Accept Custom Logo

Drawing Format: 3D/CAD/DWG//STEP/PDF .etc

Service: Customized OEM ODM CNC Machining

Processing Type: Axis CNC Machining Service and anodized