Ball mill bearing customization refers to the production process of customizing bearings for customers according to the specific working conditions, performance requirements and operating environment of the ball mill. This includes selecting suitable materials, designing reasonable structures, and formulating precise manufacturing processes to ensure that the bearings can meet the special needs of the ball mill and improve the service life and operating efficiency of the equipment.

1.The process of ball mill bearing customization

The process of ball mill bearing customization mainly includes the following steps:

Material selection: according to the operating environment of the ball mill, load size, speed and other parameters, select the appropriate bearing material, such as bearing steel, bronze, pasteurized alloy and so on.

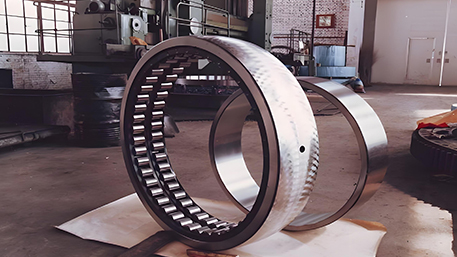

Structural design: according to the specific structure and working principle of the ball mill, design the structure of the bearing, including the size, shape and arrangement of the inner and outer rings, rolling bodies, cages and other components.

Forging and heat treatment: Forging the bearing material to improve the denseness and fluidity of its organization structure, and then heat treatment, such as quenching and tempering, to improve the wear resistance, hardness and service life of the bearing.

Grinding and superfinishing: the inner and outer rings of the bearings are ground to improve their precision and surface quality, and then superfinishing is carried out to further reduce the surface roughness and improve the smooth running of the bearings.

Assembly and testing: the inner and outer rings, rolling elements, cage and other parts of the bearing are assembled and strictly tested to ensure that the quality and performance of the bearings meet the design requirements.

2. Commonly used materials for ball mill bearing customization

The commonly used materials for ball mill bearing customization mainly include:

Bearing steel: with high hardness, high wear resistance and high fatigue strength, it is one of the most commonly used materials for manufacturing bearings.

Bronze: with good wear resistance and corrosion resistance, it is suitable for manufacturing bearings with heavy loads, low speeds and the need for corrosion resistance.

Bachmann alloy: excellent wear resistance, corrosion resistance and anti-seize, suitable for manufacturing heavy load, high speed and need good lubrication bearings.

Ceramic material: with high hardness, high wear resistance and low coefficient of friction, suitable for manufacturing high temperature, high speed and need very low friction bearings.

3. What are the characteristics of customized ball mill bearings?

The characteristics of customized ball mill bearings mainly include:

High precision: Through precise manufacturing process and strict quality control, the precision and dimensional stability of the bearings are ensured to improve the smoothness and reliability of the equipment operation.

High wear resistance: adopt high quality materials and reasonable structural design to improve the wear resistance of the bearings and prolong the service life of the equipment.

Good lubrication performance: according to the operating characteristics of the ball mill and lubrication requirements, customize the appropriate lubrication method and lubricant to ensure good lubrication of the bearings and reduce friction and wear.

High bearing capacity: according to the load size and operating conditions of the ball mill, design reasonable bearing structure and size to ensure that the bearings can withstand enough load to ensure the normal operation of the equipment.

Good adaptability: according to the specific working environment and performance requirements of the ball mill, customize the suitable bearing types and specifications to ensure that the bearings can adapt to different working conditions and operating environments.

Conclusion

The customization of ball mill bearings is a complex and delicate work, which requires comprehensive consideration of materials, processes, design and other aspects. Through reasonable customization, it can ensure that the bearings can meet the special needs of the ball mill and improve the service life and operating efficiency of the equipment. At the same time, customized bearings can also provide better adaptability and flexibility to meet the individual needs of different customers.