Q1: Let’s Start Simple—What Is CNC Machining, Exactly?

Q2: How Is CNC Machining Different From Traditional Manual Machining?

|

Feature

|

CNC Machining

|

Traditional Manual Machining

|

|

Control

|

Computer program (no human 干预 during cutting)

|

Operator’s hands/eyes (adjusts tools manually)

|

|

Precision

|

±0.001mm–±0.01mm (e.g., a phone case’s holes line up perfectly)

|

±0.1mm–±0.5mm (e.g., two wooden spoons might have slightly different handles)

|

|

Consistency

|

100+ identical parts (e.g., 500 bike pedal brackets all fit the same frame)

|

Parts vary—even from the same operator

|

|

Complexity

|

Handles curved surfaces, tiny holes (e.g., a medical implant’s tiny grooves)

|

Limited to simple shapes (e.g., straight cuts, basic holes)

|

|

Efficiency

|

24/7 operation (unmanned night shifts for high-volume parts)

|

Stops when the operator rests (max 8–10 hours/day)

|

Q3: What Kinds of Parts and Materials Can CNC Machining Make?

- Small parts: Phone case frames, watch gears, medical syringe tips (0.5mm diameter).

- Medium parts: Bike pedal brackets, laptop hinges, power tool housings.

- Large parts: Aerospace engine components (e.g., turbine blades), construction equipment hydraulic valves.

|

Material Type

|

Examples

|

Common Uses

|

|

Metals

|

Aluminum, stainless steel, titanium

|

Bike parts (aluminum), kitchen tools (stainless steel), medical implants (titanium)

|

|

Plastics

|

ABS, PEEK, acrylic

|

Lego bricks (ABS), aerospace parts (PEEK), display cases (acrylic)

|

|

Other Materials

|

Wood, carbon fiber, ceramics

|

Furniture prototypes (wood), drone frames (carbon fiber), engine parts (ceramics)

|

Q4: Are There Different Types of CNC Machining? What Are They?

|

Type of CNC Machining

|

How It Works

|

Best For

|

Example Part

|

|

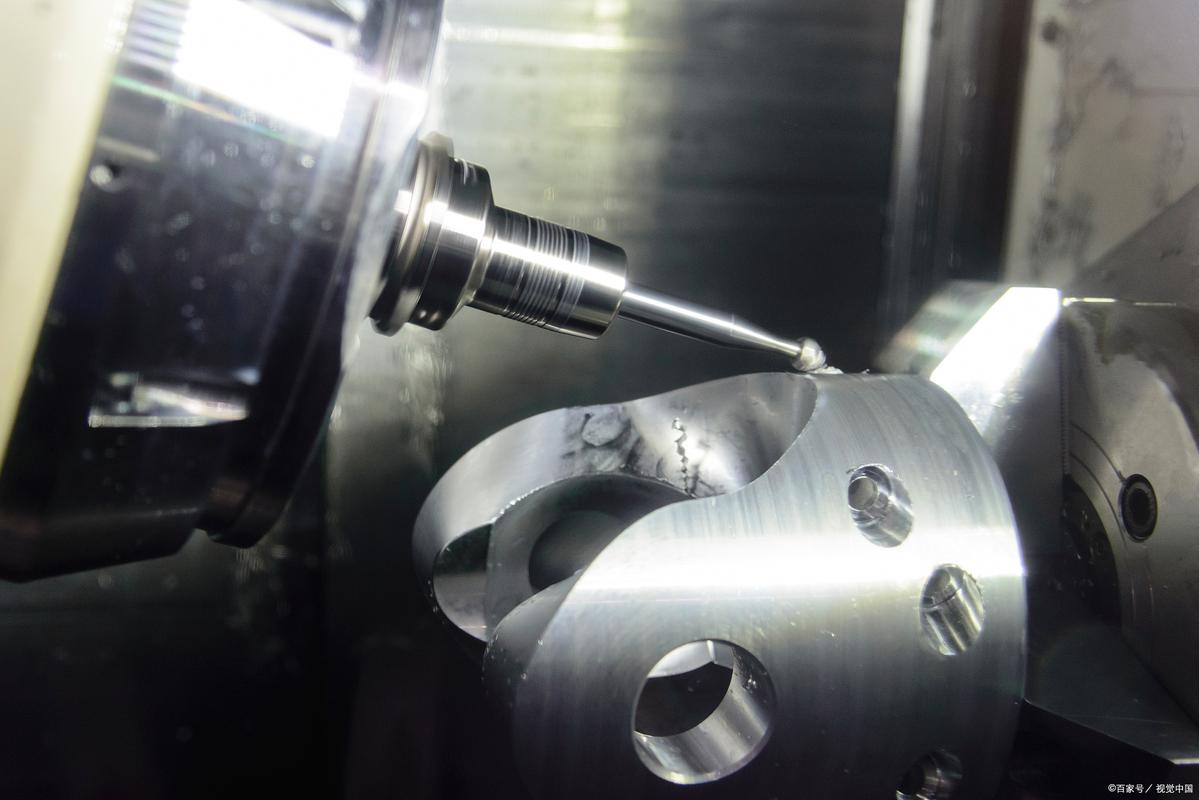

CNC Milling

|

Rotating tool cuts a stationary material (3–5 axes for 3D shapes).

|

3D parts with curves or multiple features.

|

Phone case frames, engine brackets.

|

|

CNC Turning

|

Material spins; a stationary tool cuts it (like a potter’s wheel with a knife).

|

Round/cylindrical parts.

|

Bolts, pens, hydraulic valve cores.

|

|

CNC EDM

|

Uses electrical sparks to “erode” hard materials (no physical cutting).

|

Hard metals (titanium) or tiny holes.

|

Medical implant grooves, turbine blade cooling holes.

|

|

CNC Waterjet

|

High-pressure water (plus abrasives) cuts material (no heat).

|

Heat-sensitive materials (glass) or thick metal.

|

Glass shelves, thick steel plates for construction.

|

Q5: What Do You Need to Run a CNC Machining Process?

- CNC Machine: The “hands” of the process—e.g., a CNC mill for 3D parts, a CNC lathe for round parts. Desktop models (for hobbyists) cost (1,500–)3,000; industrial models (for factories) cost $50,000+.

- CAD Software: Creates the digital design (blueprint) of the part—e.g., Fusion 360 (free for hobbyists), SolidWorks (industrial). For a wooden spoon, you’d draw the spoon’s shape in CAD.

- CAM Software: Converts the CAD design into “G-code” (the language CNC machines understand)—e.g., Mastercam, Carbide Create. The CAM software tells the machine how to cut the spoon (speed, depth, path).

Q6: Why Do Companies Use CNC Machining Instead of Other Methods (Like 3D Printing)?

- Precision & Strength: CNC-machined metal parts are stronger than 3D-printed ones (no layer lines) and more precise—critical for parts like medical implants (which need to fit perfectly in the body) or aerospace components (which can’t fail).

- Speed for High Volumes: For 100+ parts, CNC machining is faster than 3D printing. A CNC mill can make 50 plastic phone cases in 1 hour; a 3D printer might take 5 hours.

- Material Versatility: Unlike 3D printing (which mostly uses plastics/ resins), CNC machining works with hard metals (titanium, stainless steel) and natural materials (wood, stone)—ideal for industries like automotive or construction.

Q7: Is CNC Machining Hard to Learn? Can Hobbyists Do It?

- Pick a Simple Project: Start with something small (e.g., a wooden keychain) instead of a complex part (e.g., a phone case).

- Use Affordable Tools: Get a desktop CNC machine (e.g., Shapeoko, Glowforge) for (1,500–)3,000—they’re pre-assembled and come with easy-to-use software.

- Learn Free Software: Use Fusion 360 (free for hobbyists) to design parts—they have step-by-step tutorials for beginners (no CAD experience needed).

Q8: Which Industries Rely Most on CNC Machining?

- Automotive: Makes engine parts (crankshafts), brake brackets, and transmission components—CNC ensures all parts fit perfectly (no loose brakes or leaky engines).

- Medical: Creates implants (artificial hips, dental crowns) and surgical tools—CNC’s precision ensures implants match a patient’s body (no rejection or discomfort).

- Aerospace: Builds turbine blades, aircraft frames, and satellite components—CNC machining handles super-hard materials (titanium) and tight tolerances (±0.001mm) that are critical for safety.

- Electronics: Makes phone case frames, laptop hinges, and 5G antenna parts—CNC’s consistency ensures electronics fit together (no wobbly laptop screens).

- DIY/Hobby: Hobbyists use desktop CNC machines to make custom signs, jewelry, and furniture prototypes—CNC turns creative ideas into physical parts.