A CNC machining platform is a comprehensive service platform that integrates CNC technology, advanced machining equipment and specialized software systems. It not only provides high-precision machining capability, but also integrates the whole chain of services such as design, simulation, programming, production monitoring, etc., aiming to provide customers with one-stop, high-performance CNC machining solutions. The CNC machining platform optimizes the production process, improves machining accuracy and efficiency through digital and intelligent means, and meets the modern manufacturing industry’s demand for high quality, high efficiency and high flexibility.

1. Xiamen Goldcattle CNC machining platform

1.1 Platform Overview

Xiamen Goldcattle CNC machining platform, as a leader in the industry, is committed to providing customers with a full range of customized CNC machining services. Relying on advanced machining equipment and professional technical team, we have created a comprehensive service platform integrating design, manufacturing and testing.

1.2 Equipment Strength

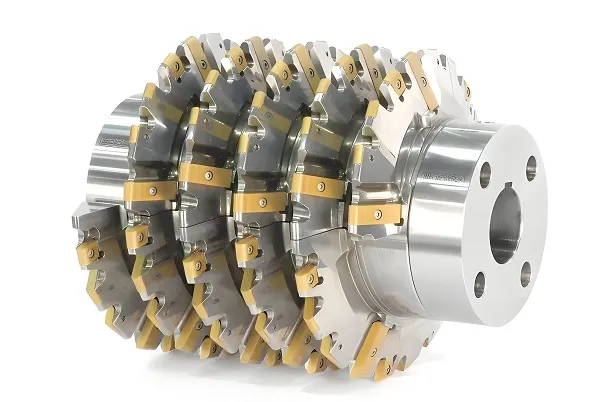

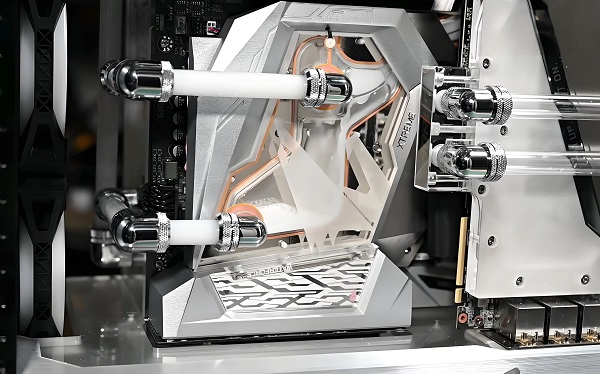

The platform is equipped with several high-precision, multi-functional CNC machining equipment, including five-axis linkage machining centers, high-speed milling centers, laser cutting machines, etc., which can meet the processing needs of various complex parts. At the same time, we regularly maintain and upgrade the equipment to ensure processing accuracy and stability.

1.3 Software system

We adopt international leading CAD/CAM software, such as SolidWorks, UG NX, etc., for 3D modeling and process programming. These software have powerful design functions and simulation capabilities, which can help customers quickly complete product design and generate accurate machining codes.

1.4 Technical Team

Xiamen Goldcattle has a technical team composed of senior engineers and technicians. They are not only proficient in CNC machining technology, but also have rich industry experience and innovation ability, which can provide customers with professional technical support and solutions.

1.5 Quality Control

We have established a strict quality control system for each processing link. Through sophisticated testing equipment and strict quality standards, we ensure that each product meets customer requirements and industry norms.

2. CNC machining platform services

2.1 Design Consultation

Provide professional design consulting services, including product structure design, process analysis, etc., to help customers optimize the design scheme and improve the machinability and performance of products.

2.2 Programming and Simulation

Utilize advanced CAD/CAM software for programming and simulation to ensure the accuracy and efficiency of the machining path and reduce the cost of trial and error in the machining process.

2.3 Machining Production

We provide one-stop processing and production services from raw material procurement to finished product delivery. We make reasonable processing plans and schedules according to customers’ needs to ensure that the production tasks are completed on time and in good quality.

2.4 Quality Inspection

We carry out comprehensive quality inspection on the finished products, including dimensional measurement, shape and position tolerance testing, surface roughness testing, etc., to ensure the traceability and stability of product quality.

2.5 After-sales support

Provide perfect after-sales support services, including product installation, debugging, training and so on. We pay close attention to customer feedback and needs, and constantly optimize the service process to improve customer satisfaction.

3. CNC machining platform customization

Xiamen Goldcattle CNC machining platform provides flexible customization services to meet the diverse needs of customers. Whether it is single part machining or mass production projects, we can provide personalized solutions according to the specific needs of customers. Through customized services, we help our customers to reduce costs, improve efficiency and enhance market competitiveness.

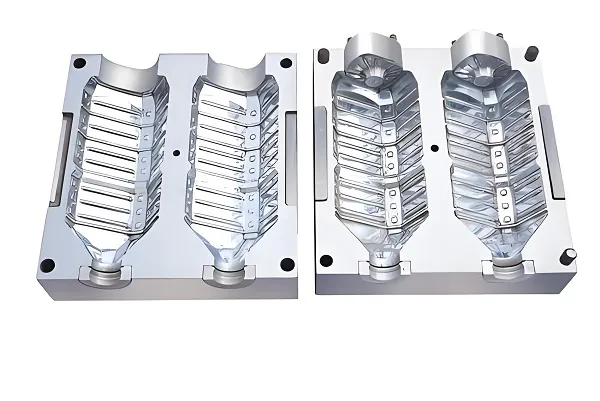

4. CNC machining platform product areas

Our CNC machining platforms are widely used in a variety of fields, including but not limited to aerospace, automotive manufacturing, mold and die manufacturing, medical equipment, electronics and telecommunications. In these fields, we have successfully provided high-quality CNC machining services for many well-known enterprises, and won wide praise and trust from our customers.

CNC Machining Platform FAQ

Q: What industries are CNC machining platforms suitable for?

A: CNC machining platforms are suitable for all industries that require high precision, high efficiency, and high flexibility in machining, such as aerospace, automotive manufacturing, and mold manufacturing.

Q: How do you ensure machining accuracy and efficiency?

A: We ensure machining accuracy and efficiency through advanced machining equipment, professional technical team and strict quality control system. We also use CAD/CAM software for programming and simulation to optimize machining paths and cutting parameters.

Q: How long does the customized service take?

A: The time for customized services varies depending on the complexity of the project and the amount of machining. Generally speaking, we will fully communicate with the customer to understand the specific needs and then develop a detailed machining plan and schedule. We will do our best to shorten the customization cycle and ensure on-time delivery of products.