Custom acetal parts, crafted from polyoxymethylene (POM), serve as high-performance components in precision engineering, offering a unique combination of mechanical strength, wear resistance, and dimensional stability. These thermoplastic parts are engineered for applications requiring low friction, chemical resistance, and consistent performance across varying temperatures. This article details the technical aspects of custom acetal manufacturing, covering material properties, machining processes, design considerations, and industry-specific implementations.

1. Acetal Material Properties and Grades

Acetal’s distinct characteristics make it a preferred material for precision components:

Key mechanical properties (ASTM D638):

- Tensile strength: 60-70 MPa (copolymer) vs. 70-80 MPa (homopolymer)

- Flexural modulus: 2.8-3.2 GPa (copolymer) offering better impact resistance

- Hardness: 85-95 Shore D, maintaining rigidity while resisting permanent deformation

- Coefficient of friction: 0.15-0.3 (dry), comparable to lubricated metals, reducing wear in dynamic applications

Thermal performance:

- Continuous operating temperature: -40°C to 100°C (short-term up to 120°C)

- Melting point: 165-175°C (copolymer) vs. 175-185°C (homopolymer)

- Low coefficient of thermal expansion: 1.5-2.0 × 10⁻⁴ /°C, minimizing dimensional changes with temperature fluctuations

Chemical resistance:

- Resistant to hydrocarbons, alcohols, and weak acids (pH 4-10)

- Limited resistance to strong acids, alkalis, and chlorinated solvents

- Meets FDA 21 CFR 177.2470 standards for food contact applications (specific grades)

Common grades include:

- Copolymer acetal: 70% of custom parts due to better processability and impact resistance

- Homopolymer acetal: Used for higher strength requirements, with 10-15% greater tensile strength

- Glass-filled acetal (10-30% glass): Increases stiffness by 50-80% for structural components

- UV-stabilized acetal: Extends outdoor service life to 5+ years by resisting photodegradation

2. Precision Machining Processes for Acetal

Acetal’s machinability enables tight tolerances and complex geometries through specialized techniques:

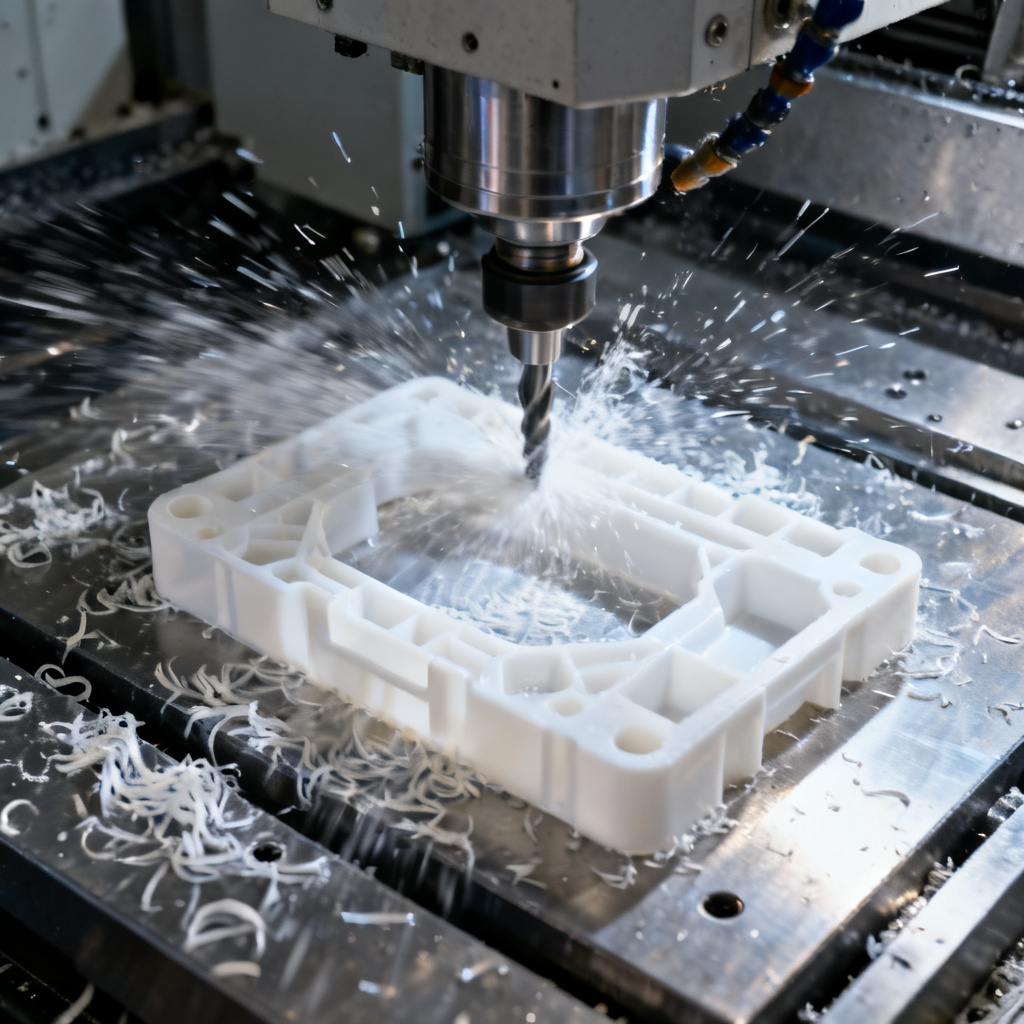

CNC milling of acetal components achieves:

- Dimensional tolerances of ±0.02 mm for general applications, ±0.01 mm for precision parts

- Surface finishes as fine as Ra 0.8 μm using carbide tools with high cutting speeds

- Spindle speeds: 3,000-6,000 RPM with feed rates 100-300 mm/min (optimized to reduce melting)

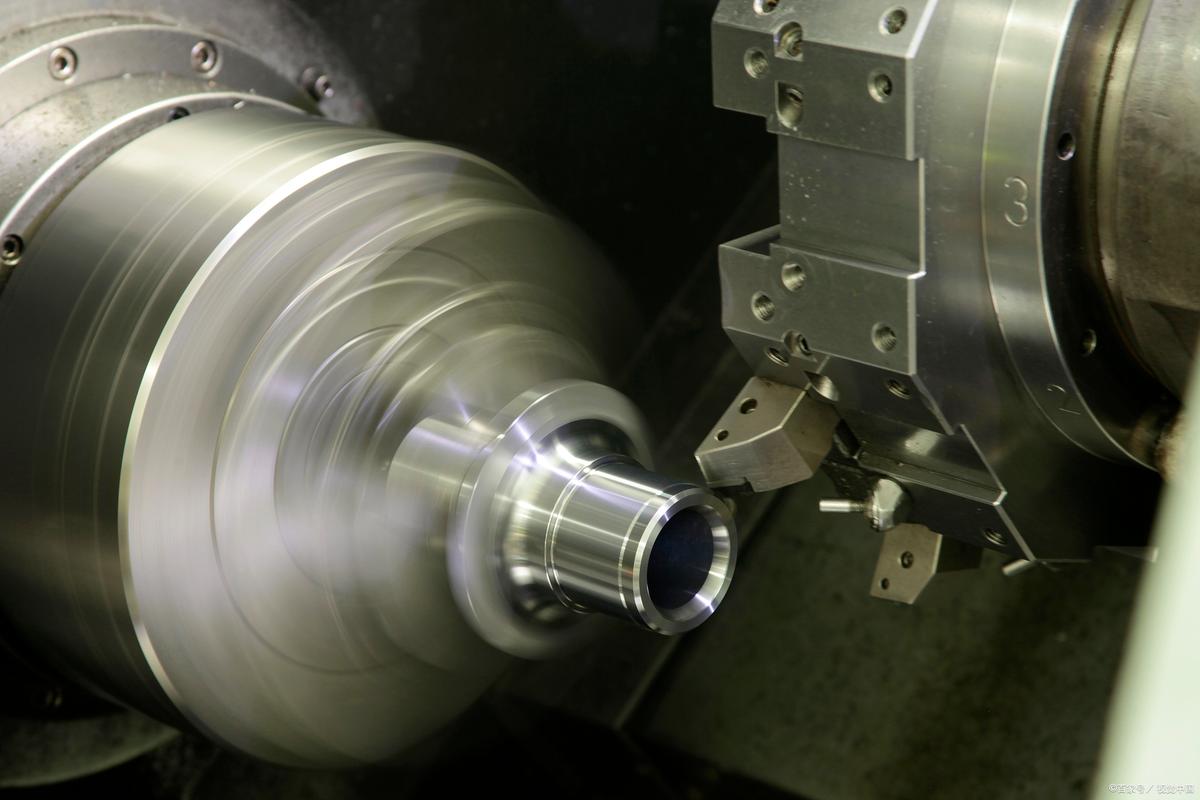

CNC turning operations produce cylindrical acetal parts with:

- Outer diameter tolerances of ±0.015 mm

- Concentricity within 0.03 mm for rotating components

- Live tooling for integrated features (threads, slots) reducing secondary operations by 40%

Injection molding for high-volume acetal parts:

- Achieves dimensional accuracy of ±0.05 mm per 100 mm length (accounting for 1.5-3% shrinkage)

- Production rates of 1,000-10,000 pieces per hour for small components

- Mold temperatures: 80-120°C to optimize crystallinity and reduce post-molding warpage

Key machining considerations:

- Use of compressed air cooling (instead of liquid coolants) to prevent material swelling

- Sharp tooling with positive rake angles (10-15°) to minimize cutting forces and burr formation

- Chip breakers to prevent stringing, common in thermoplastic machining

3. Design Parameters for Custom Acetal Parts

Acetal part design requires consideration of material behavior and manufacturing constraints:

Dimensional ranges:

- Standard CNC machined parts: 0.5 mm to 1,000 mm in length/width

- Injection molded parts: 0.1 g to 5 kg in weight, with wall thickness 0.5-10 mm

Critical design features:

- Wall thickness: Uniform sections (±10%) to prevent sink marks; minimum 0.5 mm for small parts, 1 mm for large components

- Radii and fillets: Minimum 0.5 mm internal radii to reduce stress concentration (failure risk reduced by 60%)

- Draft angles: 0.5-2° for molded parts to facilitate ejection, reducing mold release force by 30%

- Threads: Minimum 2× diameter length for sufficient strength; recommended thread forms include metric (ISO) and UNC/UNF

Tolerance capabilities:

- CNC machined: ±0.01 mm for dimensions <50 mm; ±0.02 mm for 50-200 mm

- Injection molded: ±0.03 mm for dimensions <50 mm; ±0.05 mm for 50-200 mm

- Flatness: 0.1 mm/m for machined parts; 0.2 mm/m for molded components

Shrinkage considerations:

- Copolymer acetal: 1.5-2.5% linear shrinkage (molded parts)

- Homopolymer acetal: 2.0-3.0% linear shrinkage, requiring larger mold compensation

- Anisotropic shrinkage: 10-15% greater in flow direction vs. cross direction

4. Quality Control and Testing Standards

Rigorous testing ensures acetal parts meet performance requirements:

Dimensional verification:

- CMM (Coordinate Measuring Machine) inspections with ±0.001 mm accuracy

- Optical comparators for complex profiles, ensuring ±0.005 mm conformity

- Laser scanning for 3D form analysis, critical for assembly-fit components

Mechanical property testing:

- Tensile testing (ASTM D638) to verify 60-80 MPa strength

- Impact testing (ASTM D256): 2-10 kJ/m² notched Izod impact resistance

- Wear testing (ASTM G99): Volumetric wear rate <10⁻⁶ mm³/N·m for bearing applications

Environmental performance testing:

- Thermal cycling: -40°C to 100°C for 1,000 cycles with <0.1% dimensional change

- Chemical immersion: 100-hour exposure to oils, fuels, and cleaning agents with <2% weight gain

- UV exposure (ASTM G154): 1,000 hours with <5% tensile strength reduction (UV-stabilized grades)

Industry-specific certifications:

- FDA compliance (21 CFR 177.2470) for food contact components

- RoHS compliance for electronics applications

- ISO 10993 biocompatibility for medical device components (selected grades)

5. Industry-Specific Applications

Custom acetal parts serve critical roles in diverse sectors:

Food processing equipment:

- Conveyor components (guides, pulleys) with FDA-compliant grades, resisting cleaning agents (caustic solutions up to pH 12)

- Wear strips with low friction (μ=0.2) to reduce energy consumption by 15%

- Temperature range: -20°C to 90°C, compatible with washdown procedures

Automotive systems:

- Fuel system components (valve seats, pump housings) resistant to gasoline and diesel

- Window regulator parts with 50,000+ cycle life under -40°C to 80°C conditions

- Gear racks and pinions with dimensional stability (±0.02 mm) for precise motion control

Medical devices:

- Surgical instrument components (handles, gears) with 0.8 μm surface finish to prevent bacterial adhesion

- Drug delivery system parts (pistons, valves) meeting ISO 10993 biocompatibility

- Autoclave compatibility (121°C, 30 minutes) for reusable devices

Consumer electronics:

- Wearable device housings with impact resistance (5 kJ/m²) and UV stability

- Connector components with tight tolerances (±0.01 mm) for reliable mating

- Keyboard mechanisms with low friction for 10+ million actuation cycles

Industrial machinery:

- Bearing cages and bushings with PV limit 1.5 MPa·m/s (dry operation)

- Gear components with 200+ MPa fatigue strength for 10,000-hour service life

- Chain guides with abrasion resistance exceeding 50,000 cycles in dusty environments

6. Production Capabilities and Lead Times

Manufacturing capacities accommodate diverse production requirements:

- Prototyping: 1-10 pieces via CNC machining, 3-5 business days turnaround

- Low-volume production: 10-500 pieces, 5-10 business days (CNC machining)

- Medium production: 500-10,000 pieces, 10-15 business days (combination of machining and molding)

- High-volume production: 10,000+ pieces, 15-30 business days (injection molding with dedicated tooling)

Minimum order quantities:

- CNC machining: 1 piece (no tooling costs)

- Injection molding: 5,000+ pieces (tooling investment required)

Value-added services:

- Assembly with metal inserts (ultrasonic insertion achieves pull-out force >500 N)

- Surface treatments: Anti-static coatings (surface resistance 10⁶-10⁹ Ω) for electronics

- Custom packaging: Cleanroom packaging (Class 8) for medical and electronics applications

Global supply chain capabilities:

- Regional production hubs for reduced lead times (2-5 days shipping)

- Inventory management programs for JIT delivery (98% on-time rate)

- Material traceability documentation retained for 7+ years

7. Cost Factors and Engineering Optimization

Pricing is influenced by design complexity, volume, and material selection:

Material costs:

- Copolymer acetal: (5-)8 per kg (raw material)

- Homopolymer acetal: 15-20% premium over copolymer

- Glass-filled acetal: 30-40% premium due to reinforced properties

- Specialty grades (FDA, UV-stabilized): 20-30% additional cost

Processing costs:

- CNC machining: (50-)150 per hour (varies by complexity)

- Injection molding: Tooling costs (5,000-)20,000 (one-cavity mold) with (0.10-)1.00 per piece production cost

- Secondary operations (threading, assembly): add 10-30% to base cost

Volume-based pricing:

- 100 pieces: Base price (machining-dominated)

- 1,000 pieces: 15-20% reduction (optimized toolpaths)

- 10,000 pieces: 30-40% reduction (molding becomes cost-effective)

Design optimization opportunities:

- Consolidating multiple parts into one component reduces assembly costs by 40%

- Standardizing wall thickness reduces machining time by 25%

- Incorporating draft angles in molded parts reduces tooling complexity and cost

Frequently Asked Questions

Q: What is the maximum operating temperature for acetal parts?

A: Acetal maintains mechanical properties up to 100°C continuously, with short-term exposure to 120°C possible. Extended exposure above 120°C causes gradual degradation of tensile strength (10% loss after 1,000 hours at 120°C).

Q: How does acetal compare to nylon in wear applications?

A: Acetal offers lower friction (μ=0.15 vs. 0.25 for nylon) and better dimensional stability (lower moisture absorption: 0.2% vs. 2.5% for nylon), making it superior for precision wear components like gears and bushings.

Q: Can acetal parts be sterilized?

A: Yes, copolymer acetal withstands 100+ autoclave cycles (121°C, 15 psi) with minimal property loss. Homopolymer grades are less suitable for repeated sterilization due to higher sensitivity to moisture.

If you need custom acetal parts for your application, our engineering team can provide tailored solutions based on your performance requirements. Whether you require FDA-compliant components for food processing, wear-resistant parts for industrial machinery, or precision gears for medical devices, we offer both CNC machining and injection molding capabilities to meet your volume needs. Contact us with your drawings or specifications—we’ll deliver material recommendations, design optimizations, and production timelines to ensure your acetal parts perform reliably in their intended environment.