At XM GoldCattle, we’ve spent over two decades turning raw metal into precision masterpieces in our bustling workshop. As of November 2025, custom CNC machining isn’t just a service—it’s the bridge between your innovative ideas and reliable, high-performance parts. If you’re new to this world (and many of our clients start that way), you might wonder: What exactly is CNC, and why does “custom” matter? Think of it like a high-tech sculptor: Instead of chisels and guesswork, we use computer-guided tools to carve exact shapes from materials like aluminum or titanium, ensuring every piece fits your unique specs. In this guide, we’ll walk you through the basics, peek behind the scenes in our shop, and share practical insights to demystify the process. Whether you’re an engineer prototyping a drone frame or a business owner exploring manufacturing options, our goal is to make CNC feel approachable and actionable.

Demystifying CNC: The Basics for First-Timers

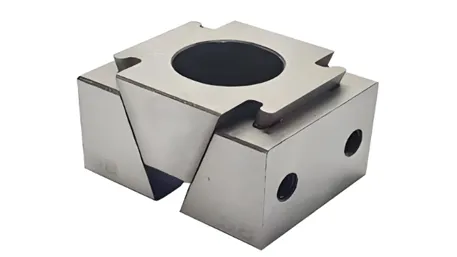

Let’s start with the fundamentals—because skipping these can lead to common mix-ups, like confusing CNC with 3D printing (which adds material, while CNC subtracts it). CNC stands for Computer Numerical Control, a method where software directs machines to cut, mill, or drill with pinpoint accuracy. No more relying on skilled hands alone; the computer handles the math, so a part that might take hours manually can be done in minutes with tolerances as fine as a human hair’s width (±0.001 inches).

Why go custom? Off-the-shelf parts are like buying ready-made clothes—they might fit okay, but for specialized needs (say, a custom gear for an electric vehicle), one-size-fits-all falls short. Customization means tailoring every step to your design: material choice, shape complexity, and finish quality. In our experience, this approach cuts waste by up to 20% and speeds up prototypes from weeks to days. For beginners, here’s a simple breakdown of the core process:

| Step | What Happens | Why It Matters (Beginner Tip) |

|---|---|---|

| Design | You send a digital file (like a CAD model) of your part. | It’s like sketching a blueprint—get it right here to avoid costly tweaks later. Free tools like Tinkercad make this easy for non-experts. |

| Programming | Software translates your design into “instructions” (G-code) for the machine. | Think of it as a recipe; our team simulates it first to catch errors, preventing real-world mishaps. |

| Machining | The machine cuts the material on axes (3 for basics, 5 for curves). | Safety first: Machines hum loudly, so ear protection is non-negotiable—even pros like us wear it! |

| Finishing & Check | Polish, inspect, and test the part. | We use calipers and scanners to verify—imagine a final exam ensuring your part won’t fail in use. |

This flow isn’t magic; it’s engineered reliability, honed in workshops like ours to serve industries from automotive to medical devices.

Inside Our Workshop: A Day in Custom CNC Processing

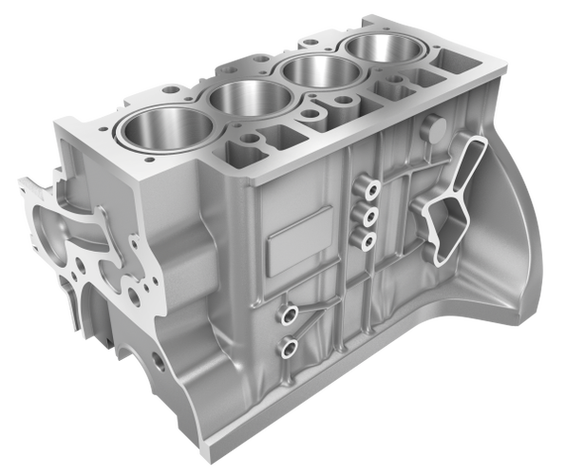

Step into our XM GoldCattle facility on any given day, and you’ll hear the steady whir of spindles and see sparks fly under controlled lights—it’s organized chaos that produces precision. Our 10,000-square-foot shop houses a fleet of 5-axis CNC mills and lathes, each calibrated daily to maintain micron-level accuracy. For a custom aluminum housing we recently machined for a European robotics firm, the process unfolded like this:

It started at 8 AM with our lead programmer reviewing the client’s CAD file on a workstation. “This one’s tricky—curved internals for better airflow,” she noted, tweaking the toolpath in Fusion 360 software to avoid collisions. By 9:30, the billet (a raw aluminum block) was clamped into the Haas VF-2 mill, secured with soft jaws to prevent slippage—a small detail that saves hours of rework.

As the machine kicked in, coolant misted the air to keep temperatures steady (overheating warps metal, a newbie pitfall we explain to all clients). The 5-axis setup shone here: While a 3-axis machine might need three repositionings (risking alignment errors), ours handled the curves in one go, shaving 40% off the cycle time. Midway, our operator paused for a vibration check—sensors flagged a minor tool wear, swapped in seconds to keep quality pristine.

By noon, the rough cut was done; afternoon brought finishing passes with a finer end mill for that silky Ra 16 surface finish. Quality control wrapped it: CMM (coordinate measuring machine) scans confirmed every dimension, and a quick hardness test ensured durability. The part shipped next day, transforming a client’s prototype into a production-ready component. This isn’t isolated—our team handles 50+ custom jobs weekly, blending human oversight with machine smarts to bridge the “blind spots” like hidden stresses in titanium that only experience reveals.

Techniques and Tips: Custom CNC Wisdom from the Floor

Drawing from our workshop logs, here are battle-tested techniques to make custom CNC work for you—explained plainly to fill those knowledge gaps:

- Material Matching 101: Not all metals play nice with every job. Aluminum’s lightweight and machinable (great for aerospace), but titanium resists wear yet “gums up” tools if speeds are off. Tip: Start with samples—we often run test cuts on scrap to dial in feeds (e.g., 50-100 inches per minute for stainless), avoiding the costly surprise of a jammed spindle.

- Toolpath Tricks for Efficiency: Custom parts thrive on smart programming. Use “adaptive clearing” strategies—spiraling cuts that maintain constant tool engagement—to reduce heat and extend tool life by 25%. For beginners: Visualize it as mowing a lawn in efficient loops, not back-and-forth lines that wear paths unevenly.

- Overcoming Common Hurdles: Chatter (vibrations causing rough finishes) plagues many setups. Our fix? Rigid fixturing and balanced tools—simple upgrades that boost precision without fancy add-ons. And for sustainability (a hot topic in 2025), we opt for biodegradable coolants, cutting environmental impact while keeping parts clean.

These aren’t textbook ideals; they’re from real runs, like optimizing a batch of 500 automotive brackets where AI-assisted paths predicted and prevented a 10% scrap rate.

2025 Horizons: What’s Shaping Custom CNC Next

Looking ahead from our shop floor, 2025’s trends are making custom machining more accessible and green. AI isn’t sci-fi anymore—it’s in our predictive software, forecasting tool breaks to minimize downtime by 30%. VR simulations let clients “walk through” their part’s creation virtually, easing design tweaks without physical prototypes. On-demand manufacturing is booming too: Short runs for custom EV components, powered by automated loading arms that free operators for creative oversight.

Energy efficiency rounds it out—new spindles in our lineup sip 20% less power, aligning with global pushes for sustainable shops. For newcomers, this means lower costs and faster iterations, turning “what if” ideas into “here’s how.”

Partnering for Your Custom CNC Journey

At XM Gold Cattle, custom CNC is about partnership—demystifying the tech so you focus on innovation. We’ve seen firsthand how filling those blind spots (from basic axes to advanced simulations) unlocks potential for clients worldwide.

What’s puzzling you about CNC customization—a material mystery or process step? Drop it in the comments below; our workshop team loves sharing fixes. Ready to prototype? Head to https://www.xmgoldcattle.com/introduction-to-cnc-services/ for a no-obligation chat and quote. Let’s craft something extraordinary together.