Heavy equipment parts are the backbone of machines like excavators, bulldozers, and tractors—think of them as the tough, hardworking components that keep construction sites, farms, and mines running. From massive gears to tiny hydraulic fittings, these parts take a beating: dirt, heavy loads, and nonstop use. Custom heavy equipment parts are built to fit specific machines or tough jobs, replacing worn-out originals or upgrading weak spots where off-the-shelf parts just can’t keep up.

1. Why Custom Heavy Equipment Parts?

Let’s face it—standard parts are made for “average” machines and typical work. But if you’ve got an older excavator, a modified tractor, or a machine working in extreme conditions (like mining in mud or construction in freezing temps), stock parts fail fast. They’ll wear unevenly, break under stress, or just not fit right.

Custom parts solve that. Need a thicker gear for a bulldozer that pushes boulders? A longer hydraulic hose for a lifted crane? A corrosion-resistant bracket for a marine dredger? Custom builds match your machine’s exact specs and work demands. They also save you from the headache of hunting for discontinued OEM parts—we’ve all been there, scrolling through endless catalogs with no luck.

Custom parts solve that. Need a thicker gear for a bulldozer that pushes boulders? A longer hydraulic hose for a lifted crane? A corrosion-resistant bracket for a marine dredger? Custom builds match your machine’s exact specs and work demands. They also save you from the headache of hunting for discontinued OEM parts—we’ve all been there, scrolling through endless catalogs with no luck.

2. How Custom Heavy Equipment Parts Are Made

- Forging: This is like metal blacksmithing on steroids. We heat steel or iron until it’s red-hot, then hammer or press it into shape. Forging makes parts super dense and strong—perfect for gears, axles, or anything that takes heavy loads. It’s how you get parts that won’t bend when a bulldozer pushes a boulder.

- Welding: For big parts like bucket lips or frame reinforcements, we use heavy-duty welding. TIG or MIG welds melt metal together, creating bonds stronger than the original material. Think of it as gluing metal with fire—done right, these welds last for years, even in gritty conditions.

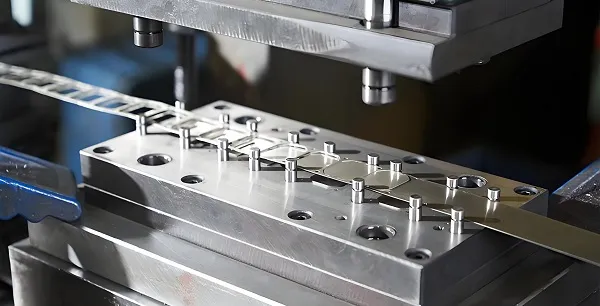

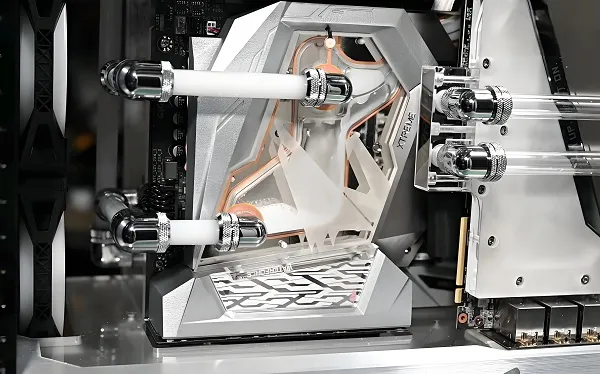

- CNC Machining: For precision parts like hydraulic valve bodies or bearing housings, we use computer-controlled machines. These “smart tools” carve metal with tiny tolerances (like 0.001 inches), ensuring parts fit like a glove. No more wobbly connections or leaky hydraulics.

- Casting: For complex shapes—like engine blocks or pump housings—we pour molten metal into molds. Casting lets us make intricate parts with hollow sections or weird curves that would be impossible to weld or machine.

- Heat Treatment: After shaping, we heat parts and cool them slowly to make them harder or more flexible. A hardened gear tooth resists wear; a flexible spring pin bends instead of breaking under shock.

3. The Process of Making Custom Heavy Equipment Parts

- Talk Shop: First, we’ll chat about your machine—make, model, age—and what’s going wrong. Is a gear wearing out too fast? A hose keeps bursting? We’ll measure the old part (or your machine’s specs) to get exact dimensions.

- Design It: Using CAD software, we’ll draft a 3D model. We’ll tweak it together—thicker here, longer there—to match your work. Want a reinforced edge on a bucket? We’ll add it.

- Pick the Metal: Not all steel is the same. We’ll help you choose: high-carbon steel for strength (gears, axles), stainless steel for rust resistance (marine equipment), or cast iron for durability (engine parts).

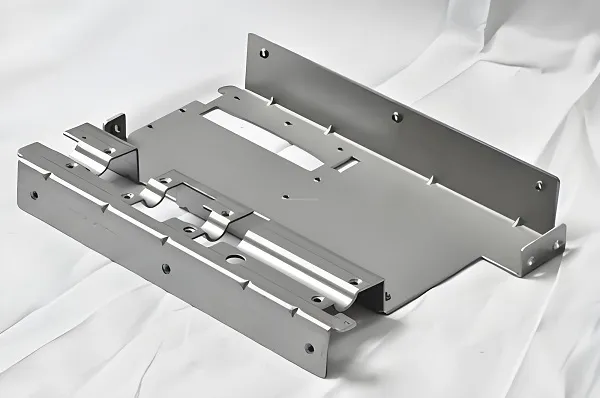

- Shape & Form: Depending on the part, we’ll forge, weld, machine, or cast it. For a bucket tooth, that might mean forging a steel blank, then machining the sharp edge. For a hydraulic bracket, CNC machining from a solid steel block.

- Toughen It Up: Heat treatment, grinding, or coating. A gear gets hardened to resist wear; a bolt gets zinc-plated to fight rust; a bucket edge gets a hardfacing weld (like adding a layer of super-tough metal) to chew through rocks.

- Test It: We’ll fit the part to your machine (or a mockup) to check for gaps, leaks, or wiggles. A hydraulic fitting must seal tight; a gear must mesh smoothly. If it’s not right, we tweak it—no guesswork.

4. Materials for Custom Heavy Equipment Parts

- High-Carbon Steel: The workhorse. Tough, affordable, and easy to weld/forge. Great for gears, axles, and bucket teeth—anything that needs to handle heavy impacts without bending.

- Alloy Steel (4140): Steel mixed with chromium and molybdenum. Stronger than carbon steel and more resistant to fatigue. Perfect for parts that get stressed over and over, like crane cables or hydraulic cylinder rods.

- Stainless Steel (316): Fights rust like a champ. Use it for parts in wet or salty environments—marine dredgers, snowplows that use salt, or mining equipment in rainy climates. It’s pricier, but worth it to avoid seized bolts or corroded brackets.

- Cast Iron: Super durable and cheap to cast. Ideal for engine blocks, pump housings, or any part that needs to handle heat and vibration without cracking.

- Hardfacing Alloys: Special metals (like chromium carbide) welded onto parts as a “wear layer.” Think of it as adding a metal armor to bucket edges, plow blades, or crusher jaws—they’ll chew through rock and gravel without wearing down.

5. Where Custom Heavy Equipment Parts Are Used

- Construction: Excavator buckets (with reinforced edges), bulldozer track links (extra-thick for rough terrain), crane hydraulic cylinders (longer for tall lifts).

- Mining: Crusher jaws (hardfaced to resist wear), conveyor belt rollers (stainless steel to fight corrosion), drill rig gears (tough alloys for deep drilling).

- Agriculture: Tractor axle housings (reinforced for heavy loads), combine harvester cutter bars (sharpened and hardened), irrigation pump parts (rust-resistant for water).

- Forestry: Log skidder winch gears (strong enough to pull trees), mulcher blades (hardfaced for chopping wood), crane booms (lightweight but strong for lifting logs).

- Marine & Dredging: Dredge pump impellers (stainless steel to fight saltwater), barge anchor brackets (welded for strength), tugboat hydraulic hoses (flexible for rough seas).

6. Extra Features for Better Performance

- Wear Resistance: Hardfacing, chrome plating, or ceramic coatings. These add a tough layer to parts that grind against dirt, rock, or gravel—bucket edges last 2-3x longer with hardfacing.

- Corrosion Protection: Zinc plating, powder coating, or stainless steel. No more rusted bolts seizing up or brackets crumbling in saltwater or rain.

- Reinforced Designs: Extra metal in stress spots—like a thicker flange on a gear or a gusset (triangular brace) on a frame. These prevent cracks where parts bend or twist.

- Easy Maintenance: Adding grease fittings to bearings, or making parts modular (so you can replace just a worn edge instead of the whole part). Saves time and money on repairs.

7. Common Questions About Custom Heavy Equipment Parts

-

How long do custom parts last compared to stock?

Depends on the part and work, but usually 2-5x longer. A hardfaced bucket edge might last 1,000 hours instead of 300; a reinforced gear could outlive your machine if maintained. -

Are custom parts more expensive than stock?

Upfront, yes—they’re made just for you. But they save money long-term: fewer replacements, less downtime, and no more buying 3 stock parts that don’t fit right. -

Can you make a part for a 30-year-old machine?

Absolutely. We’ve reverse-engineered parts from rusted-out originals, old blueprints, or even just measurements of the machine itself. If it exists (or existed), we can make it. -

How long does it take to get a custom part?

Small parts (like brackets) take 1-2 weeks. Big, complex parts (like gears or buckets) take 3-6 weeks. We can rush jobs if you’re stuck—just ask! -

Do I need to send you the old part?

It helps, but not always. We can work from measurements, photos, or machine specs. If the part is broken, send it—we’ll see where it failed and make the new one stronger.

Need a custom part to keep your heavy equipment running? Whether you’re fixing an old excavator, upgrading a tractor, or just can’t find that one discontinued part, we’ve got your back. Drop a comment with your machine details, what part you need, and what it’s used for—our team will chat through options, materials, and timelines. Let’s get your equipment back to work, no more breakdowns!