- Safety & Environmental Compliance: Containers in direct food contact must pass migration tests (heavy metals ≤0.1ppm, plasticizers ≤0.05ppm).

- Functional Adaptability:

- Storage boxes must support ≥15kg stacking load without deformation after 24 hours.

- Kitchen utensils require knife resistance (hardness ≥2H) and easy cleaning (surface roughness Ra ≤0.8μm).

- Design Flexibility: Support personalized coloring (Pantone matching ΔE ≤1.0), ergonomic handles (grip force ≤3N), and stackable structures (misalignment ≤2mm).

- Technical Advantages:

- Dimension accuracy ±0.1%, supporting complex structures (clasps, threads, transparent/opaque co-injection molding).

- Multi-cavity mold design (32–64 cavities per mold), production efficiency 2,000–5,000 pieces/hour, suitable for 10g–5kg products.

- Process Parameters:

- Injection pressure 80–150MPa, mold temperature 40–80°C, cooling time 10–25 seconds.

- Shrinkage control: 1.5%–2.0% for PP, 0.4%–0.7% for ABS, ensuring component fit precision.

- Technical Highlights:

- Multi-layer co-extrusion combines wear-resistant/color/load-bearing layers, extending service life by 25%.

- Bottle mouth precision control ±0.2mm ensures cap sealing (leakage rate ≤0.01mL/min).

- Process Advantages:

- Minimum wall thickness 0.3mm, 40% lighter than injection molding, material utilization ≥95%.

- Rapid prototyping for small batches (1–1,000 pieces), mold cost 60% lower than injection molding.

- Key Parameters:

- Heating temperature 180–240°C, forming pressure 0.5–1.0MPa, suitable for PS/PE materials.

- Dimension accuracy ±0.5mm, ideal for thin-wall products like disposable meal boxes and storage baskets.

- Technical Features:

- Supports complex curves (streamlined handles, hollow patterns), minimum detail size 0.5mm.

- Options for photosensitive resin (accuracy ±0.1mm) and PLA eco-material (biodegradation rate ≥90%).

- Application Scenarios:

- Custom bathroom fixtures (unique towel racks), DIY gardening tool accessories (accuracy ±0.2mm).

- Multi-Dimensional Design Support:

- Structural Optimization: Finite element analysis optimizes handle stress distribution, ensuring 10,000-cycle grip fatigue test without breakage.

- Functional Customization:

- Moisture-Proof Storage Boxes: Sealant compression 20%–30%, humidity barrier ≥95% (50°C/90%RH environment).

- Children’s Tableware: Obtuse angles (R ≥5mm), non-slip base friction coefficient ≥0.6, compliant with EN 71-3 heavy metal standards.

- Precise Material Selection:

- Food Contact Scenarios: FDA-certified PP with migration test results: lead ≤0.05ppm, phthalates ≤0.01%.

- Outdoor Products: PE with UV-531 additive, weather resistance QUV-A 2,000 hours color difference ΔE ≤3.

- Pre-Processing Technology:

- Raw Material Modification: Antibacterial additives (bacteriostasis rate ≥99%) for bathroom products, mold resistance grade 0 (GB/T 2423.16).

- Surface Treatment: Matte/gloss finish with roughness controlled at Ra 0.2–3.2μm to meet texture requirements.

- Flexible Manufacturing Capability:

- Rapid Prototyping: 3D printed samples delivered in 48 hours, aluminum mold development cycle 10–15 days (steel mold 30–45 days).

- Mass Production:

- High-Speed Injection Line: Haitian injection molding machines (clamping force 500–2,000 tons), daily output 10,000–50,000 pieces.

- Blow Molding Line: Automatic hollow forming machines support 24/7 production of 100mL–20L products.

- Comprehensive Testing System:

- Physical Properties:

- Drop Test: 1.2m drop to concrete floor, breakage rate ≤1% (100-piece sample).

- Fatigue Test: Drawer rail push-pull life ≥10,000 cycles, deformation ≤1mm.

- Chemical Properties:

- Detergent Resistance: 5% laundry detergent immersion for 72 hours without discoloration/swelling.

- Heavy Metal Detection: ICP-MS analysis results 50% better than GB 4806.1-2016 standards.

- Environmental Certifications: REACH and RoHS reports ensure no SVHC substances.

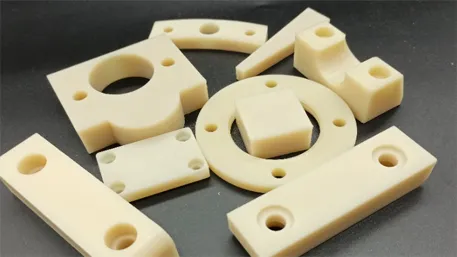

- Storage Boxes: PP material with reinforcing ribs, 20kg load-bearing capacity, clasp structure achieving IP54 sealing grade.

- Drawer Dividers: ABS injection molding, dimension accuracy ±0.3mm, customizable partition solutions (error ≤1mm).

- Food Containers: PET transparent material with silicone seals, airtightness maintaining 50kPa pressure for 30 minutes, extending freshness by 20%.

- Cutting Boards: High-density PE with antibacterial surface, knife marks ≤0.5mm, compliant with NSF food processing standards.

- Bathroom Sets: PVC thermoformed with non-slip bases, water absorption ≤0.1%, resistant to soap water (pH 9–11) for 200 hours.

- Plant Pots: PP + fiberglass reinforcement, 2% UV additive, 5-year outdoor service life without embrittlement (elongation at break ≥20%).

- Toy Organizers: Rounded edges (R ≥3mm), ABS material with matte finish, 500g steel ball drop test from 1m without cracks.

- Baby Tableware: Food-grade PP with anti-scald design, heavy metal migration ≤0.01ppm, passing EN 14372 child safety certification.