Machining small parts refers to the precision manufacturing of components with dimensions typically under 10mm, requiring tight tolerances (often ±0.001mm to ±0.01mm). These parts—such as micro screws, tiny gears, and miniature connectors—demand exceptional accuracy to function in compact assemblies. Custom machining of small parts tailors these components to unique designs, material needs, and application requirements, ensuring reliability in high-precision systems across industries.

1. Why Custom Machining Small Parts

Standard small parts rarely meet the unique demands of specialized applications, which often require non-standard sizes, intricate geometries, or compatibility with custom assemblies. Custom machining solves this by producing parts with precise dimensions—such as a 0.5mm-diameter pin or a 2mm gear—that off-the-shelf components cannot match.

Customization enables optimization for specific environments: corrosion-resistant materials for medical devices, high-strength alloys for aerospace micro-components, or non-magnetic metals for electronics. For industries like robotics or microelectronics, custom small parts ensure seamless integration into compact systems, reducing assembly gaps and improving performance. Additionally, custom machining allows for intricate features (e.g., micro-threads, tiny holes) that standard parts lack, critical for functionality in precision instruments.

2. Machining Small Parts Processing Technologies

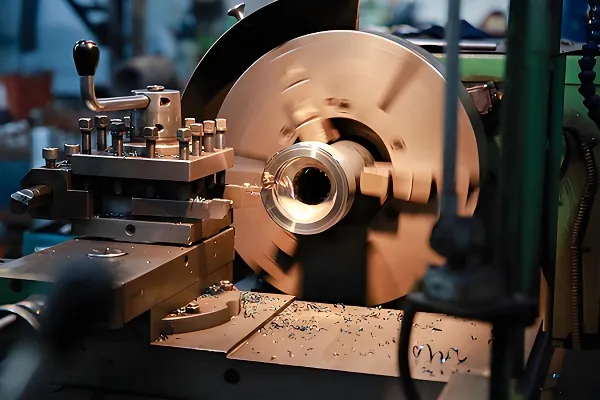

- Swiss CNC Turning: Specialized for long, slender small parts (e.g., needles, micro shafts) with diameters as small as 0.1mm. Uses a guide bushing to minimize deflection, achieving tight tolerances and smooth surfaces.

- Micro Milling (3-Axis/5-Axis): Cuts complex 3D features (e.g., micro-grooves, tiny cavities) in small workpieces using high-speed spindles (up to 60,000 RPM). Ideal for non-cylindrical parts like micro brackets.

- Wire EDM: Uses electrical discharges to cut ultra-fine shapes (e.g., 0.05mm slots) in hardened materials, ensuring precision without mechanical stress—critical for brittle materials like ceramics.

- Laser Micromachining: Ablates material with laser beams to create micro-features (e.g., holes as small as 5μm) in metals, plastics, or composites. Suitable for heat-sensitive or fragile small parts.

- Electrochemical Machining (ECM): Shapes small parts through controlled electrolysis, ideal for complex geometries (e.g., micro-nozzles) with no tool wear, ensuring consistency in high-volume production.

3. Machining Small Parts Processing Flow

- Design & Engineering: Collaborate to define part specs (dimensions, tolerances, features) and application needs (load, environment). Use CAD/CAM software with micro-design tools to model parts and simulate toolpaths.

- Material Selection: Choose materials based on size and function—titanium for lightweight strength, stainless steel for corrosion resistance, or PEEK for high-temperature stability in micro-components.

- Prototype Development: Produce test parts using 3D printing (for plastics) or micro-milling (for metals) to validate fit and functionality. Adjust designs based on prototype feedback.

- Precision Machining: Select the appropriate technology (e.g., Swiss turning for shafts, micro-milling for gears) and set up specialized fixtures to secure tiny workpieces. Use ultra-fine tools (0.1mm diameter) for detailed features.

- Post-Processing: Remove burrs with ultrasonic cleaning or micro-abrasive blasting. Apply heat treatment (e.g., annealing) to enhance strength or surface coatings (e.g., gold plating) for conductivity.

- Quality Inspection: Use high-magnification tools (microscopes, CMMs with micro-probes) to verify dimensions. Test surface finish with profilometers and check for defects like micro-cracks.

4. Machining Small Parts Materials

-

- Stainless Steel (316L): Corrosion-resistant and biocompatible, ideal for medical small parts (e.g., surgical instrument components).

-

- Titanium (Grade 5): High strength-to-weight ratio, used in aerospace micro-shafts and lightweight connectors.

-

- Brass: Excellent conductivity and machinability, suitable for micro-electrical connectors and tiny valves.

-

- PEEK: Heat-resistant and chemical-stable, used for small parts in high-temperature environments (e.g., micro-pumps).

-

- POM (Acetal): Low friction and dimensional stability, ideal for micro-gears and sliding components.

-

- Alumina: Hard and wear-resistant, used for small bearings and high-precision insulators in electronics.

5. Machining Small Parts Applications

- Medical Devices: Micro screws for orthopedic implants, tiny needles for drug delivery systems, and miniature valves for diagnostic equipment—all requiring biocompatibility and precision.

- Electronics & Microelectronics: Connector pins (0.2mm diameter), micro heat sinks, and tiny capacitors for smartphones, wearables, and semiconductor equipment.

- Aerospace & Robotics: Micro gears for drone motors, small actuators for satellite systems, and lightweight fasteners for compact aerospace assemblies.

- Precision Instruments: Micro-calibration screws for optical devices, tiny springs for pressure sensors, and miniature nozzles for inkjet printers.

- Automotive Electronics: Small terminals for sensors, micro-connectors for ADAS systems, and tiny relays for compact control modules.

6. Machining Small Parts Performance Additions

- Surface Finishing: Electropolishing to achieve Ra 0.02μm surfaces, reducing friction in sliding micro-components (e.g., gears, valves).

- Coatings: Gold or nickel plating for conductivity (electrical connectors) or PTFE coatings for low friction (sliding parts).

- Micro-Threading: Precision-cut threads (as small as M0.6) for secure fastening in miniature assemblies, ensuring tight joins without stripping.

- Heat Treatment: Case hardening (e.g., carburizing) for small metal parts to enhance surface strength while maintaining core ductility.

- Dimensional Stabilization: Annealing to reduce internal stresses, preventing warping in tiny parts (e.g., micro-shafts) under thermal or mechanical load.

7. Machining Small Parts Common Questions

- What is the smallest part size that can be machined?

We regularly produce parts with dimensions as small as 0.1mm (diameter for shafts) and 0.05mm (feature size for grooves/holes), using specialized Swiss turning and laser micromachining.

- How tight of tolerances can be achieved?

For metal parts, tolerances of ±0.001mm are achievable for critical features; plastic parts typically range from ±0.005mm to ±0.01mm, depending on material stability.

- Which materials are most challenging to machine for small parts?

Brittle materials like ceramics and thin-walled metals (e.g., 0.1mm stainless steel) require slow feed rates and specialized tools to avoid cracking or deformation.

- What is the lead time for custom small parts?

Prototypes take 1–3 weeks; production runs (100–10,000 units) take 2–5 weeks, depending on complexity. Rush options are available for urgent projects.

- How to ensure consistency in high-volume small parts production?

We use automated loading systems, in-process inspection with micro-probes, and strict tool wear monitoring to maintain consistency across thousands of parts.

Need custom machined small parts for your project? Whether you require micro gears for robotics, tiny medical components, or precision electronics parts, we can deliver parts tailored to your specs. Share your design details, material preferences, and volume needs in the comments, and our team will provide technical insights, cost estimates, and production timelines. Let’s bring your small-part designs to life!