Threaded machined parts are components featuring precision-cut helical grooves (threads) designed to fasten, connect, or transmit motion between mechanical elements. These threads—whether external (bolts, screws) or internal (nuts, tapped holes)—enable secure, adjustable joins, with tight tolerances ensuring compatibility and reliability. Custom threaded parts are tailored to unique dimensions, thread types (metric, UNC, NPT), and performance needs, serving as critical elements in machinery, construction, and industrial systems.

1. Why Custom Threaded Machined Parts

Standard threaded parts often fail to meet the unique demands of specialized applications, which require non-standard sizes, unusual thread pitches, or compatibility with custom components. Custom threaded parts solve this by delivering precise fits for unique assemblies—whether a 0.5mm-pitch screw for microelectronics or a large NPT pipe thread for industrial plumbing—that off-the-shelf parts cannot provide.

Customization enables optimization for specific environments: corrosion-resistant threads for marine equipment, high-strength threads for structural bolts, or fine threads for precision instruments (e.g., medical devices). For industries with strict standards (aerospace, automotive), custom parts can be engineered to meet regulatory requirements (AS9100, ISO 898) and performance criteria (tensile strength, fatigue resistance). Additionally, custom threading allows for integration with other features (flanges, knurls) in a single part, reducing assembly steps and improving overall system efficiency.

Customization enables optimization for specific environments: corrosion-resistant threads for marine equipment, high-strength threads for structural bolts, or fine threads for precision instruments (e.g., medical devices). For industries with strict standards (aerospace, automotive), custom parts can be engineered to meet regulatory requirements (AS9100, ISO 898) and performance criteria (tensile strength, fatigue resistance). Additionally, custom threading allows for integration with other features (flanges, knurls) in a single part, reducing assembly steps and improving overall system efficiency.

2. Threaded Machined Parts Processing Technologies

- Thread Turning: Uses a lathe with thread-cutting tools to create external threads (bolts, studs) or internal threads (nuts) on cylindrical workpieces. Ideal for single-start or multi-start threads with moderate precision (±0.05mm).

- Tapping: Creates internal threads using a tap—either hand-driven (for low volumes) or machine-driven (for high volumes). Suitable for blind holes (threads not 贯穿 the part) or through holes in materials like aluminum, steel, or plastic.

- Thread Rolling: Forms threads by compressing material with hardened dies, cold-working the surface to increase strength. Produces stronger threads than cutting (up to 30% higher fatigue resistance) and is ideal for high-volume production of bolts or screws.

- Thread Milling: Uses CNC mills with multi-tooth cutters to create complex threads (e.g., tapered, left-hand, or non-circular) in a single setup. Offers high precision (±0.01mm) and works well for large or hard materials (titanium, stainless steel).

- Thread Grinding: Finishes threads with abrasive wheels to achieve ultra-precise dimensions (±0.002mm) and smooth surfaces, critical for high-performance applications (aerospace fasteners, precision gauges) where minimal friction is required.

3. Threaded Machined Parts Processing Flow

- Design & Engineering: Collaborate with clients to define thread specifications (type, pitch, diameter), material requirements, and tolerance levels. Use CAD/CAM software to model threads and simulate fit with mating components.

- Material Selection: Choose materials based on application needs—steel for strength, stainless steel for corrosion resistance, aluminum for lightweight, or titanium for high-performance environments.

- Pre-Machining: Cut raw material into blanks (bars, rods) and shape basic forms (cylindrical shafts, hexagonal heads) using turning or milling, ensuring proper dimensions for threading.

- Thread Processing: Select the appropriate method (turning, tapping, rolling, milling) based on thread type and volume. For example, thread rolling is used for high-volume bolts, while thread milling suits complex, large threads.

- Heat Treatment: Harden parts (e.g., quenching and tempering for steel) to enhance tensile strength and wear resistance, critical for load-bearing threads (structural bolts, automotive fasteners).

- Post-Processing: Remove burrs from thread crests, apply surface treatments (galvanizing, anodizing) for corrosion resistance, or add secondary features (washers, locknuts) for assembly.

- Quality Inspection: Verify thread dimensions using gauges (ring gauges for external threads, plug gauges for internal threads), check pitch and angle with thread micrometers, and test tensile strength for critical applications.

4. Threaded Machined Parts Materials

- Carbon Steel (1018, 1045): Cost-effective and easy to machine, used for general-purpose threads (construction bolts, hardware). 1045 offers higher strength for load-bearing applications.

- Stainless Steel (304, 316): Corrosion-resistant, ideal for threads in wet or chemical environments (marine equipment, food processing). 316 provides superior resistance to saltwater and acids.

- Alloy Steel (4140, 8620): Heat-treatable for high strength (1,000+ MPa tensile), used for critical threads (aerospace fasteners, automotive engine bolts) requiring fatigue resistance.

- Aluminum Alloys (6061, 7075): Lightweight and corrosion-resistant, suitable for threads in electronics, aerospace, or consumer goods where weight reduction is key.

- Titanium Alloys (Grade 5): Combines high strength with low weight and biocompatibility, used for threads in medical implants, aerospace components, and high-performance racing parts.

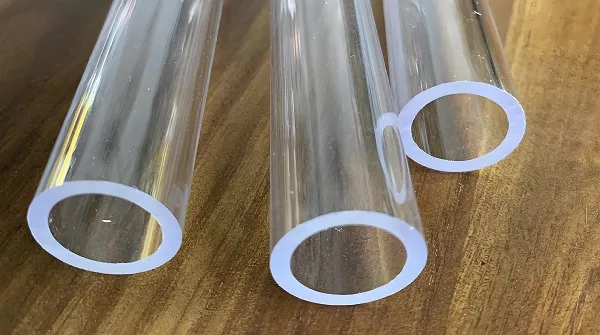

- Plastics (Nylon, PEEK): Non-conductive and chemical-resistant, used for threads in electrical insulation, medical devices, or low-strength applications (e.g., plastic enclosures).

5. Threaded Machined Parts Applications

- Aerospace & Defense: High-precision titanium or alloy steel threads for aircraft structural bolts, missile components, and satellite assemblies, meeting strict weight and strength requirements.

- Automotive Industry: Steel or stainless steel threads for engine bolts, suspension components, and chassis fasteners, engineered to withstand vibration and temperature extremes.

- Construction & Infrastructure: Large-diameter carbon steel threads for structural bolts, pipe flanges, and concrete anchors, ensuring stability in bridges, buildings, and industrial facilities.

- Medical Devices: Titanium or plastic threads for surgical instruments, implantable devices (bone screws), and diagnostic equipment, meeting biocompatibility standards (ISO 10993).

- Electronics & Precision Engineering: Fine-pitch aluminum or stainless steel threads for microscopes, sensors, and semiconductor equipment, requiring tight tolerances (±0.005mm) for precise adjustments.

- Plumbing & Fluid Systems: NPT (tapered) threads in brass or stainless steel for pipes, valves, and fittings, ensuring leak-free connections in water, gas, or chemical lines.

6. Threaded Machined Parts Performance Additions

- Surface Coatings: Zinc plating (galvanizing) for corrosion resistance in steel threads; anodizing for aluminum threads to improve wear resistance and aesthetics.

- Thread Locking Features: Integral nylon patches or pre-applied adhesives (e.g., Loctite) to prevent loosening in vibrating environments (automotive, machinery).

- Heat Treatment: Quenching and tempering to increase thread hardness (30–45 HRC) and tensile strength, critical for high-load applications (structural bolts).

- Precision Grinding: Ultra-smooth thread surfaces (Ra 0.2μm) to reduce friction and improve mating with other parts, ideal for precision instruments.

- Sealing Enhancements: Tapered threads (NPT) or thread sealant grooves to prevent fluid leakage in plumbing or hydraulic systems.

- Anti-Galling Treatments: Coatings (molybdenum disulfide) or surface finishes to prevent thread seizure in high-temperature or high-pressure applications (e.g., industrial valves).

7. Threaded Machined Parts Common Questions

-

What thread tolerances can be achieved?

Standard threads typically have tolerances of ±0.05mm; precision threads (aerospace, medical) can reach ±0.002mm with thread grinding. Tolerances depend on material (harder materials allow tighter controls) and thread size (smaller threads require finer tolerances). -

How do I choose between cut threads and rolled threads?

Cut threads are better for low volumes, complex geometries, or brittle materials (plastic, cast iron). Rolled threads offer higher strength and are more cost-effective for high-volume production of ductile materials (steel, aluminum). -

What causes thread failure?

Common causes include over-tightening (stripping), material fatigue (repeated loading), corrosion (weakening of threads), or poor fit (mismatched thread types/pitches). Proper design (stress relief features) and material selection mitigate these risks. -

Can custom threads be made compatible with standard parts?

Yes—custom threads can be engineered to mate with standard threads (e.g., a custom bolt with UNC threads to fit a standard nut) by matching pitch, diameter, and angle. -

What is the lead time for custom threaded parts?

Simple parts (e.g., bolts with standard threads) take 1–2 weeks; complex parts (e.g., large tapered threads in titanium) require 3–6 weeks, including design, machining, and testing.

Need custom threaded machined parts for your project? Whether you require high-strength bolts for structural applications, precision threads for medical devices, or corrosion-resistant fittings for marine equipment, we can deliver parts tailored to your exact specifications. Share your thread type, material preferences, and performance needs in the comments, and our team will provide design insights, cost estimates, and production timelines. Let’s create threads that secure your success!