CNC cosmetic bottle molds are precision molds designed and manufactured specifically for the cosmetic industry and are processed using computer numerical control (CNC) technology. These molds are capable of producing cosmetic bottles in a variety of shapes, sizes and functions to meet the stringent requirements of cosmetic manufacturers for product appearance, quality and production efficiency.The introduction of CNC technology has made the production of cosmetic bottle molds more precise and efficient, and brought more diversified choices to the cosmetic market.

1. CNC cosmetic bottle mold production process

1.1 Demand analysis and design

Communicate with customers to clarify the specific requirements such as the size, shape, capacity, opening and closing methods of the cosmetic bottle.

Perform 3D modeling to design the overall structure of the mold and each component to ensure compliance with the specifications of cosmetic packaging.

1.2 Material selection and procurement

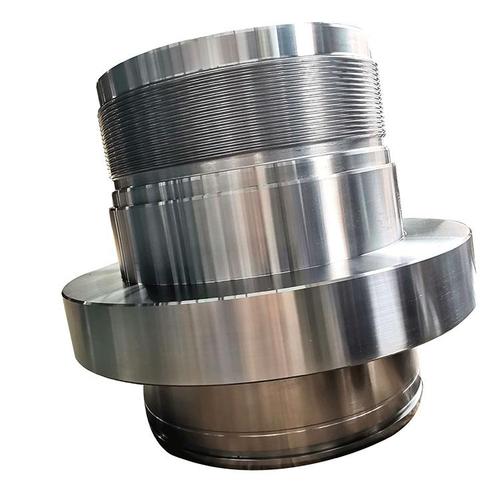

According to the use requirements of the mold, choose suitable mold materials, such as stainless steel, aluminum alloy and so on.

Purchase the mold materials from reliable suppliers and carry out the necessary inspection and pretreatment.

1.3 Processing and Manufacturing

Use CNC machine tools to carry out roughing and finishing to remove excess material and form the precise shape of the mold.

Perform precision machining such as EDM and wire cutting to ensure the details and accuracy of the mold.

Heat treat the mold to improve the hardness and wear resistance.

1.4 Assembly and debugging

Assemble the processed mold parts to form a complete mold.

Test the mold on the injection molding machine and adjust the mold structure to ensure the molding quality and production efficiency of the cosmetic bottles.

1.5 Acceptance and delivery

Conduct a comprehensive inspection of the mold to confirm that it meets the design requirements and quality standards.

Deliver qualified molds to customers and provide necessary technical support and training.

2. CNC cosmetic bottle mold processing steps

Cutting: Cut the raw material of the mold according to the design size.

CNC Rough machining: Use CNC machine tools to make preliminary cuts to form the rough contour of the mold.

Precision machining: Fine machining of the mold using EDM, WEDM and other technologies to ensure precision and surface quality.

Heat treatment: Heat treatment such as quenching and tempering is carried out on the mold to improve the hardness and wear resistance.

Polishing and assembly: polish the mold to improve the appearance quality and final assembly.

3. Customized CNC Cosmetic Bottle Mould Service

Personalized design: Provide personalized design service according to customer’s demand, including shape, color, structure and so on.

High-precision processing: Adopt advanced CNC processing technology to ensure the precision and stability of the mold.

Rapid response: Respond quickly to customer needs and provide one-stop service from design to production.

After-sales service: Provide maintenance, repair and upgrade service of the molds to ensure the long-term use of customers without worry.

4. Material for making CNC cosmetic bottle mold

Material: stainless steel (such as SUS304)

Characteristics: strong corrosion resistance, suitable for cosmetics and other chemicals packaging.

Characteristics: High temperature resistance, can maintain stability in the injection molding process.

Characteristics: high hardness, good abrasion resistance, extend the service life of the mold.

Characteristics: easy processing, suitable for complex shapes of mold manufacturing.

Characteristics: High surface finish, improve the appearance quality of cosmetic bottle.

5. CNC cosmetic bottle mold can be processed materials

Material: PET, PP, ABS and other plastics

PET: high transparency, environmental protection and non-toxic, suitable for high-end cosmetic packaging.

Characteristics: lightweight, drop-resistant, easy to carry and use.

PP: good chemical stability, acid and alkali corrosion resistance, suitable for a variety of cosmetics.

Characteristics: excellent processing performance, easy to injection molding.

ABS: high strength, impact resistance, suitable for the production of cosmetic bottles that require a certain degree of pressure resistance.

Characteristics: good surface gloss, suitable for spraying, printing and other surface treatment.

6. CNC cosmetic bottle mold processing technology

CNC numerical control machining: ensure the precise size and shape of the mold.

Precision grinding: improve the surface finish and accuracy of the mold.

EDM: to deal with the complex structure and tiny holes of the mold.

Heat treatment: Improve the hardness and wear resistance of the molds to prolong the service life.

Polishing and deburring: optimize the surface quality of the mold to ensure the appearance of the cosmetic bottle is flawless.

7. CNC Cosmetic Bottle Mould Production Equipment

High precision CNC machine tools: for roughing and finishing of the mold.

EDM machine: to deal with the complex structure and tiny features of the mold.

Wire Cutting Machine: for cutting the shaped parts and fine grain of the mold.

Heat treatment furnace: for heat treatment of molds such as quenching and tempering.

Polishing equipment: including manual polishing machine and automatic polishing machine for polishing treatment of mold surface.

Customized CNC Cosmetic Bottle Mould Service FAQ

Q1: How long does it take to customize CNC cosmetic bottle mold?

A1: The customization time depends on the complexity and quantity of the molds, usually it takes weeks to months from design to production completion.

Q2:How to ensure the precision and quality of the mold?

A2: We use advanced CNC processing technology and precision measuring equipment to ensure the accuracy and quality of the molds meet the design requirements. Meanwhile, we will carry out strict inspection and testing of the molds to ensure their stable and reliable performance.

Q3:What does the after-sales service of the mold include?

A3:Our after-sales service includes mold maintenance, repair, upgrading as well as technical support and training. We are committed to providing customers with a full range of service support to ensure that our customers can use the molds smoothly and produce high-quality cosmetic bottle products.

Q4:How long is the service life of the mold?

A4: The service life of a mold depends on a variety of factors such as the choice of material, processing technology and the environment in which it is used. Generally speaking, the carefully designed and manufactured CNC cosmetic bottle molds have high service life and stability, and can meet the long-term production needs of customers.

Q5:Can we provide sample trial service for the mold?

A5:Yes, we can provide sample trial production service for the molds. Before formal production, we can make sample molds according to customer’s requirements and conduct trial mold verification to ensure that the design and processing quality of the molds meet customer’s requirements.