1. First, Why Do We Need G01?

- G00 can move the tool to the start of the edge fast—but it can’t cut the edge smoothly;

- If you tried to cut with G00, the tool would zip across the metal too quickly, leaving rough, uneven cuts (like scribbling with a pen instead of drawing a straight line);

- G01 solves this: it moves the tool at a steady, controlled speed while cutting—so you get clean lines, smooth slopes, and accurate shapes every time.

2. What Is G01, in One Sentence?

|

Feature

|

G00 (Fast Travel)

|

G01 (Steady Cutting)

|

|

Purpose

|

Move tool (no cutting)

|

Cut material (shape part)

|

|

Speed

|

Machine’s max speed

|

Your set speed (F-value)

|

|

Path

|

May not be straight

|

Always straight line

|

|

When to use

|

Before/after cutting

|

During cutting

|

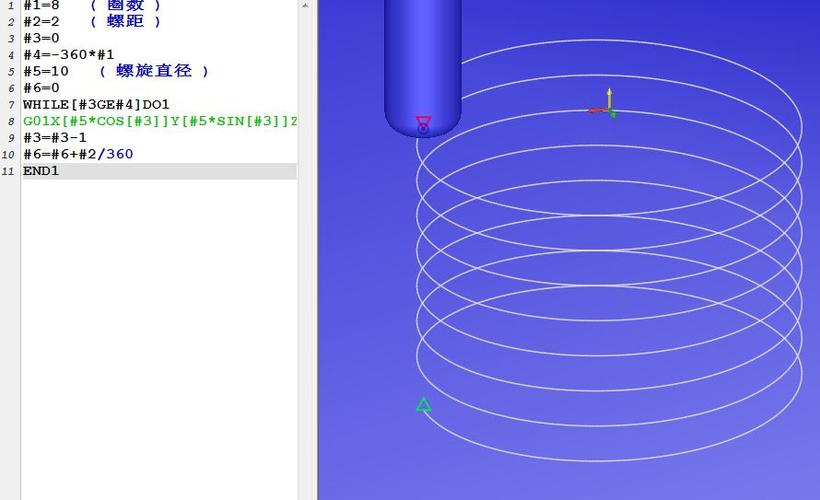

3. How to Use G01? 4 Simple Steps (With Example)

Step 1: Prep with G00 (Get to the Start)

Step 2: Set G01 and Cutting Speed (F-Value)

- G01: “Switch to steady cutting mode”;

- F100: “Cut at 100mm per minute—don’t go faster or slower!”

Step 3: Cut to the Target Position

- The tool moves slowly (F100) from Z5 down to Z-3 (cutting 3mm into the aluminum);

- At the same time, it moves straight from X10 to X60 (Y stays at 10—so it’s a straight horizontal cut);

- The path is always a straight line between the starting position (X10 Y10 Z5) and target (X60 Y10 Z-3).

Step 4: Finish with G00 (Get Away Safely)

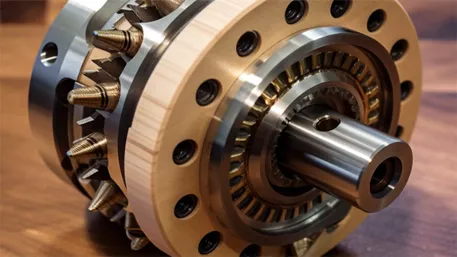

4. The Most Common Uses for G01

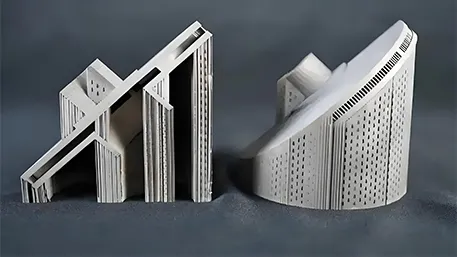

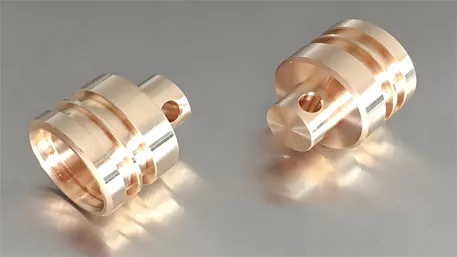

1. Straight-Line Cutting

2. Slope/Angle Cutting

3. Part Contours

5. 3 Critical Mistakes Beginners Make (And How to Fix Them)

Mistake 1: Forgetting the F-Value

- What happens: If you write G01 X60 Y10 Z-3; without F100, the machine may use a default speed (too fast/slow) or even throw an error (it doesn’t know how fast to cut!).

- Fix: Always set the F-value before your first G01 cut. Write G01 F100; right after G00.

Mistake 2: Cutting Too Deep Too Fast

- Example: Jumping from Z5 to Z-10 in one G01 line (cutting 15mm deep at once). This puts too much pressure on the tool—It will break or leave rough cuts.

- Fix: Cut in small “steps.” For a 10mm deep slot:

Mistake 3: Not Checking Tool Position Before G01

- What happens: If the tool is too close to the part (e.g., Z1 instead of Z5) when you start G01, it will crash into the material.

- Fix: Always use G00 to move to a safe Z-height (at least 5mm above the part) before switching to G01. Double-check the screen to confirm the tool’s position!

Final Summary: G01 = “Steady Cutting Mode”

- G01 is for cutting, G00 is for moving—never mix them up;

- Always set an F-value (speed) for G01—match it to your material;

- G01 cuts straight lines (or slopes) slowly and accurately—this is how you shape your part.

Disclaimer

- All information, opinions, and data contained in this article are for the purpose of information transmission only and do not constitute any advice on investment, transactions, law, medical care, or other matters.

- The content of the article is compiled based on public information or created based on the author’s personal understanding. Although every effort is made to ensure accuracy, it does not guarantee the completeness, accuracy, and timeliness of the information, nor does it bear any responsibility for any losses caused by the use of the content of this article.

- If the article involves third-party opinions, pictures, data, and other content, the copyright belongs to the original author. In case of infringement, please contact us for deletion.

- Readers should make independent decisions based on their actual situation and combined with professional opinions. The user shall bear all consequences arising from the use of the content of this article.