1. Technical Overview of High-Precision Injection Molding

High-precision plastic injection molding demands micron-level tolerances (typically ±0.01–0.05 mm) and repeatable quality across production runs. This process relies on hardened steel molds, scientific molding techniques, and closed-loop process control to minimize warpage, sink marks, and dimensional deviations. Critical industries such as medical devices, aerospace, and optical equipment require materials with exceptional stability (e.g., low hygroscopicity) and surface finish consistency. When requesting quotes, factors like tooling complexity, material selection, and post-processing requirements significantly impact costs. This guide explores technical considerations to balance precision, performance, and budget.

2. Technical Documentation: Material Selection for High-Precision Parts

Material choice directly affects dimensional accuracy and long-term performance. Below is a comparison of plastics suited for high-precision applications:

| Material | Tensile Strength (MPa) | Shrinkage Rate (%) | Thermal Stability (°C) | Cost per kg (USD) | Recommended Applications |

|---|---|---|---|---|---|

| PEEK | 90–100 | 1.2–1.5 | 250–310 | 80–120 | Aerospace, surgical instruments |

| PC | 60–70 | 0.6–0.8 | 120–135 | 4.0–5.5 | Optical lenses, connectors |

| POM (Delrin) | 60–70 | 2.0–2.5 | 90–110 | 3.5–4.5 | Gears, bearings, precision mechanisms |

| ABS | 40–50 | 0.5–0.7 | 80–100 | 2.5–3.5 | Prototyping, enclosures |

| LCP | 150–200 | 0.1–0.3 | 200–240 | 20–30 | Microelectronic components |

Engineer Recommendations:

- PEEK: For extreme thermal/chemical resistance in mission-critical parts.

- LCP: Optimal for ultra-thin walls (<0.2 mm) and minimal shrinkage.

- POM: Choose for low-friction mechanical assemblies.

- PC: Prioritize for optical clarity and moderate heat resistance.

3. Customer Case Study: Microfluidic Chip for Medical Diagnostics

Client Pain Point: A biotech firm required 10,000 microfluidic chips with 50µm channel tolerances but faced inconsistent fill rates and burr formation from existing suppliers.

Technical Challenges:

- Maintaining ±0.02 mm accuracy across 64 cavities.

- Eliminating particulate contamination for ISO Class 7 cleanroom compliance.

Solution: - Material: Medical-grade LCP with 0.2% shrinkage.

- Tooling: Mirror-polished steel mold with vacuum venting.

- Process: Electric injection molding for temperature stability (±1°C).

Results: - Yield rate improved from 78% to 99.3%.

- Unit cost reduced by 22% via optimized cycle time (18s vs. 25s).

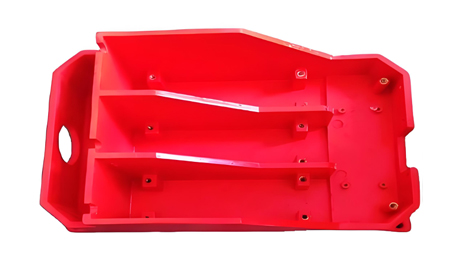

4. Surface Finishing for High-Precision Components

| Process | Characteristics | Applications |

|---|---|---|

| Mirror Polishing | Ra <0.05µm; eliminates micro-pits | Optical lenses, fluidic channels |

| Vacuum Metallizing | Adds conductive/reflective coatings | Sensors, RF shielding components |

| Chemical Etching | Micro-textures for adhesion or light diffusion | Medical implants, LED housings |

| Electropolishing | Removes surface impurities; enhances corrosion resistance | Surgical tools, lab equipment |

5. High-Precision Customization Workflow

- Specification Review: Define tolerances (ISO 2768-f), surface finish (Ra/Rz), and material certifications.

- Mold Engineering: Use 3D simulation (Moldflow) to predict shrinkage and cooling stresses.

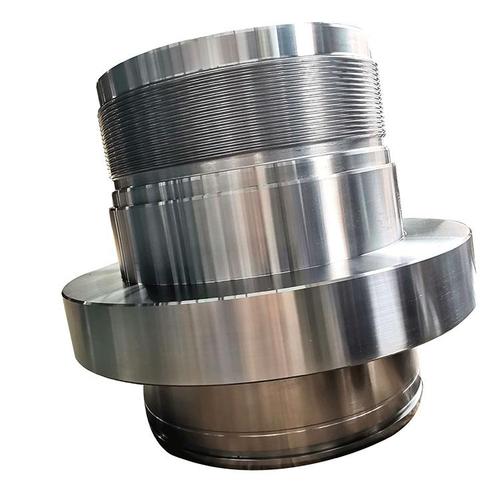

- Tooling: High-hardness steel (HRC 52–56) with EDM/texturing.

- Sampling: 5–10 validation units measured via CMM and optical comparators.

- Mass Production: 24/7 monitored runs with automated QC (SPC systems).

6. FAQ: High-Precision Molding Quotes

Q: How are tolerances verified during production?

A: Suppliers use coordinate measuring machines (CMM) and laser scanners for real-time metrology.

Q: What increases tooling costs for precision molds?

A: Factors include cavity count, surface polish requirements, and lifetime expectations (e.g., 500k vs. 1M cycles).

Q: Can recycled materials be used for high-precision parts?

A: Generally not recommended due to inconsistent shrinkage; virgin resins ensure stability.