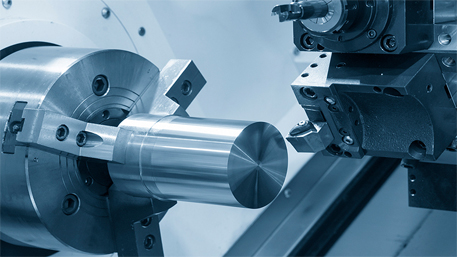

Metal parts are processed by CNC machining through the following steps:

1. Design and Programming:

- The part is first designed using CAD (Computer-Aided Design) software.

- The CAD model is then imported into CAM (Computer-Aided Manufacturing) software, where the machining operations, tool paths, and cutting parameters are programmed.

2. Material Selection:

- Appropriate metal material is chosen based on the part’s requirements for strength, hardness, corrosion resistance, and other properties. Common metals include aluminum, steel, stainless steel, titanium, etc.

3. Setup and Fixturing:

- The selected metal stock is securely fastened onto the CNC machine’s worktable using fixtures or clamping devices.

- The position of the material is accurately aligned with the machine’s coordinate system.

4. Tool Selection:

- Based on the material and the machining operations, suitable cutting tools such as end mills, drills, taps, and lathe tools are selected.

5. Machining Operations:

- Roughing: Large amounts of material are removed quickly to approach the final shape.

- Semi-finishing: Removes some of the remaining material and improves surface quality.

- Finishing: Produces the final dimensions and surface finish with high precision.

6. Cutting Parameters:

- Parameters like cutting speed, feed rate, and depth of cut are set based on the material, tool, and machining operation.

7. Coolant Application:

- Coolant is used to reduce heat, prolong tool life, and improve surface finish.

8. In-process Inspection:

- Periodically, the part is measured and inspected during machining to ensure it meets the specified dimensions and tolerances.

9. Post-processing:

- This may include deburring, polishing, heat treatment, or surface coating depending on the part’s requirements.

10. Final Inspection:

- The completed part is thoroughly inspected using precision measuring instruments to verify its quality and conformity to the design specifications.