Machining brass is generally easy due to its excellent machinability, stemming from low hardness (50–100 HB), high ductility, and ability to produce continuous, manageable chips. It requires minimal cutting force, reduces tool wear, and allows high speeds, making it suitable for both CNC and manual processes. However, challenges like burr formation and work hardening (in lead-free alloys) demand careful parameter tuning.

Detailed Analysis of Brass Machining Difficulty

1. Core Factors Making Brass Easy to Machine

Brass’s intrinsic properties simplify machining compared to metals like steel or titanium:

- Low Hardness & Strength: Brass alloys (copper-zinc) have a Brinell hardness of 50–100 HB and tensile strength of 200–500 MPa, far lower than steel (150–300 HB, 400–1,000 MPa). This reduces cutting forces by 30–50%, allowing the use of high-speed steel (HSS) tools instead of expensive carbide—ideal for small workshops. For example, a 10mm HSS drill in C36000 brass (leaded brass) maintains sharpness 2–3x longer than in 1018 steel.

- Ductility & Chip Formation: Brass forms continuous, non-abrasive chips that are easy to evacuate, reducing tool clogging. Leaded brass (C36000, 2–3% lead) performs even better: lead acts as an internal lubricant, lowering friction between the tool and workpiece. This minimizes heat buildup (cutting temperatures <200°C vs. 300–400°C in steel), preventing tool wear and material distortion.

- High Thermal Conductivity: Brass conducts heat 5–10x better than steel, dissipating cutting heat away from the tool tip. This reduces the risk of thermal damage to both the tool and workpiece—critical for precision parts like electrical connectors, where dimensional stability (±0.01mm) is key.

2. Challenges in Brass Machining

While generally easy, brass presents specific hurdles requiring mitigation:

- Burr Formation: Brass’s ductility leads to ragged edges (burrs) after machining, especially in low-speed operations. For example, drilling a 5mm hole in C26000 brass (cartridge brass) at 1,000 RPM creates larger burrs than at 3,000 RPM. Solutions include using sharp tools with positive rake angles (5–10°) to shear material cleanly and post-machining deburring (tumbling with ceramic media for 30 minutes).

- Work Hardening in Least Brass: Unleaded alloys (e.g., C69300, used in potable water systems) lack lead’s lubricating effect, increasing friction. Excessive cutting forces can harden the surface layer (by 20–30% in hardness), making subsequent operations (e.g., threading) difficult. Mitigation: Reduce feed rates by 10–15% (to 0.1–0.15 mm/rev) and use carbide tools to avoid compressing the material.

- Surface Staining: Brass is prone to tarnishing if exposed to moisture or cutting fluids with sulfur compounds. This is problematic for decorative parts (e.g., musical instrument components). Using sulfur-free coolants and drying parts immediately after machining prevents discoloration, maintaining a bright finish.

3. Optimal Machining Processes & Parameters

Brass machining requires tailored processes to balance efficiency and quality:

-

Tool Selection:

- HSS Tools: Suitable for low-volume jobs (1–100 parts) in leaded brass. HSS drills and end mills work well at 1,000–3,000 RPM, with a tool life of 500–1,000 holes in C36000 brass.

- Carbide Tools: Better for high-volume production or unleaded brass. TiN-coated carbide reduces wear by 40% vs. HSS, maintaining precision across 5,000+ parts. For fine finishes (Ra <0.8μm), use diamond tools to avoid scratching soft brass surfaces.

-

Cutting Parameters:

- Spindle Speed: 3,000–6,000 RPM for HSS tools; 5,000–10,000 RPM for carbide. Higher speeds (e.g., 8,000 RPM for a 10mm end mill) minimize burrs in leaded brass.

- Feed Rate: 0.1–0.3 mm/rev for roughing; 0.05–0.1 mm/rev for finishing. Unleaded brass requires 10–20% lower feeds to prevent work hardening.

- Coolant: Soluble oils or synthetic coolants (5–10% concentration) flush chips and prevent staining. Avoid chlorinated coolants, which can react with copper in brass, causing pitting.

-

Machining Operations:

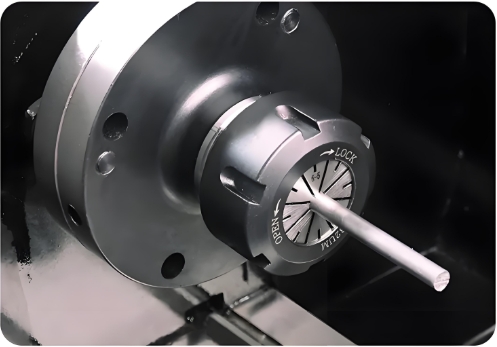

- Turning: Brass rods (10–50mm diameter) turn smoothly on CNC lathes, achieving dimensional accuracy of ±0.005mm. Use a 60° carbide insert with a 0.4mm nose radius for fine finishes on valve stems.

- Milling: 3-axis mills easily create slots and pockets in brass plates. Climb milling (tool moves with the workpiece) reduces chatter, improving surface finish on electrical terminal blocks (Ra 1.6μm).

- Drilling & Tapping: Brass taps form clean threads without cracking, even in thin walls (1mm thickness). Use spiral-point taps for through holes and spiral-flute taps for blind holes to evacuate chips.

4. Material-Specific Variations

Different brass alloys exhibit varying machinability:

- Leaded Brass (C36000, “Free-Cutting Brass”): The easiest to machine, thanks to 2–3% lead. Used for high-volume parts (fittings, connectors) with cycle times <1 minute per part. Its machinability rating (100% on the brass scale) sets the benchmark for other alloys.

- Unleaded Brass (C69300, C70600): Requires more careful machining due to higher friction. Used in potable water systems or food-grade parts, it needs carbide tools and lower feeds (0.08–0.12 mm/rev) to avoid work hardening. Machinability is 70–80% of C36000.

- High-Zinc Brass (C46400, “Naval Brass”): Contains 39–42% zinc, offering higher strength but lower machinability (60–70% of C36000). Used for marine hardware, it requires coolant with extreme pressure (EP) additives to reduce tool wear during heavy cuts.

- Specialty Alloys (C23000, Red Brass): Higher copper content (85%) improves corrosion resistance but reduces machinability (50–60% of C36000). Used in plumbing valves, it needs sharp tools and moderate speeds to prevent tearing.

5. Applications & Industry Requirements

Brass’s machinability makes it ideal for parts requiring precision and cost-efficiency:

- Plumbing & HVAC: Fittings, valves, and pipe nipples (C36000) are mass-produced with CNC lathes, achieving ±0.02mm tolerance for leak-free seals. High-speed machining (5,000 RPM) ensures 1,000+ parts per hour.

- Electronics: Connectors and terminal blocks (C26000) demand tight dimensional control (pin spacing ±0.01mm). CNC milling with carbide tools creates precise slots and contact surfaces, with post-machining polishing to ensure conductivity.

- Automotive: Fuel line fittings and sensor housings (C37700) use leaded brass for easy machining and corrosion resistance. Automated lines with robotic loading/unloading achieve 99.9% defect-free rates.

- Musical Instruments: Trumpet valves and horn slides (C27200, yellow brass) require mirror finishes (Ra <0.05μm). Diamond turning at 10,000 RPM followed by buffing creates smooth surfaces for optimal sound resonance.

6. Best Practices for Efficient Brass Machining

To maximize results while minimizing challenges:

- Prioritize Leaded Brass for Machinability: When possible (e.g., non-potable applications), use C36000 to reduce tool wear and burr formation.

- Optimize Tool Geometry: Use tools with positive rake angles (5–10°) and polished flutes to reduce friction. For drilling, parabolic flute designs enhance chip evacuation in deep holes (≥2× diameter).

- Implement Post-Machining Deburring: Use vibratory tumbling (ceramic media) or brush deburring for small parts, ensuring safety and assembly compatibility. For precision parts (e.g., aerospace connectors), laser deburring removes micro-burrs without damaging surfaces.

- Control Storage & Handling: Brass tarnishes easily—store finished parts in dry, low-humidity environments (≤50% RH) and use anti-tarnish bags for long-term storage.

In summary, brass is among the easiest metals to machine, thanks to its low hardness, ductility, and thermal properties. While challenges like burrs and work hardening exist, they are manageable with proper tooling, parameters, and process controls. This makes brass a go-to material for cost-effective, high-precision parts across industries.