1. First: What Is the “Cutting Process” We’re Talking About?

- Accuracy: Tolerances as tight as ±0.005mm (thinner than a human hair).

- Efficiency: 3–10x faster than manual cutting (e.g., 100 aluminum brackets/hour vs. 10/hour manually).

- Consistency: <1% variation across 1,000+ parts (critical for mass production).

2. Step-by-Step: How the CNC Cutting Process Is Completed

Step 1: Define Requirements (Pre-Cutting Planning)

- Material Selection: Choose based on use case—304 stainless steel is picked here for its corrosion resistance (critical for brake parts) and machinability (cuts 20% faster than 316 stainless steel).

- Tolerance Setting: ±0.1mm is specified because brake line brackets need to align with other components; looser tolerance (±0.5mm) would cause fitment issues.

- Finish Standards: “Deburred edges (Ra < 1.6μm)” (Ra = surface roughness—1.6μm is smooth enough to avoid sharp edges that damage hoses).

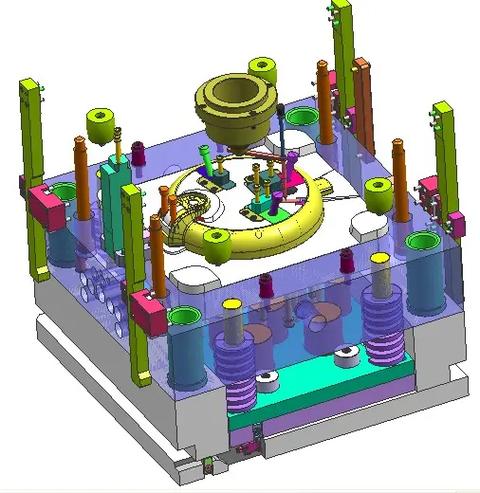

Step 2: Create a Digital Design (CAD Modeling)

- Use 3D CAD software (e.g., Fusion 360, SolidWorks) to model the bracket. For this part, the CAD file includes:

-

- Dimensions: 80mm (length) × 40mm (width) × 3mm (thickness).

-

- Features: 2 holes (6mm diameter) for mounting, 1 slot (10mm × 2mm) for the brake line.

- Design for Machinability: The slot’s 2mm width is chosen because the CNC laser cutter (used later) can handle minimum 0.5mm slots—wider slots reduce tool wear by 30%.

Step 3: Convert Design to Machine Code (CAM & G-Code)

- Import the CAD file into CAM software (e.g., Mastercam, Carbide Create). For the brake bracket:

-

- Select the cutting method: “Fiber laser cutting” (ideal for 3mm stainless steel—faster than plasma, more precise than waterjet).

-

- Set parameters (backed by material data):

-

-

- Laser power: 150W (3mm stainless steel needs 120–180W to cut through without melting edges).

-

-

-

- Feed rate: 150mm/min (slower than aluminum, which cuts at 300mm/min—stainless steel is harder).

-

-

-

- Nesting: Arrange 20 bracket designs on one 1m×1m stainless steel sheet to reduce material waste (from 25% to 8%).

-

- The CAM software outputs G-code (1,200 lines for this bracket)—e.g., G00 X10 Y10 (rapid move to start position), G01 Z-3 F150 (cut 3mm deep at 150mm/min).

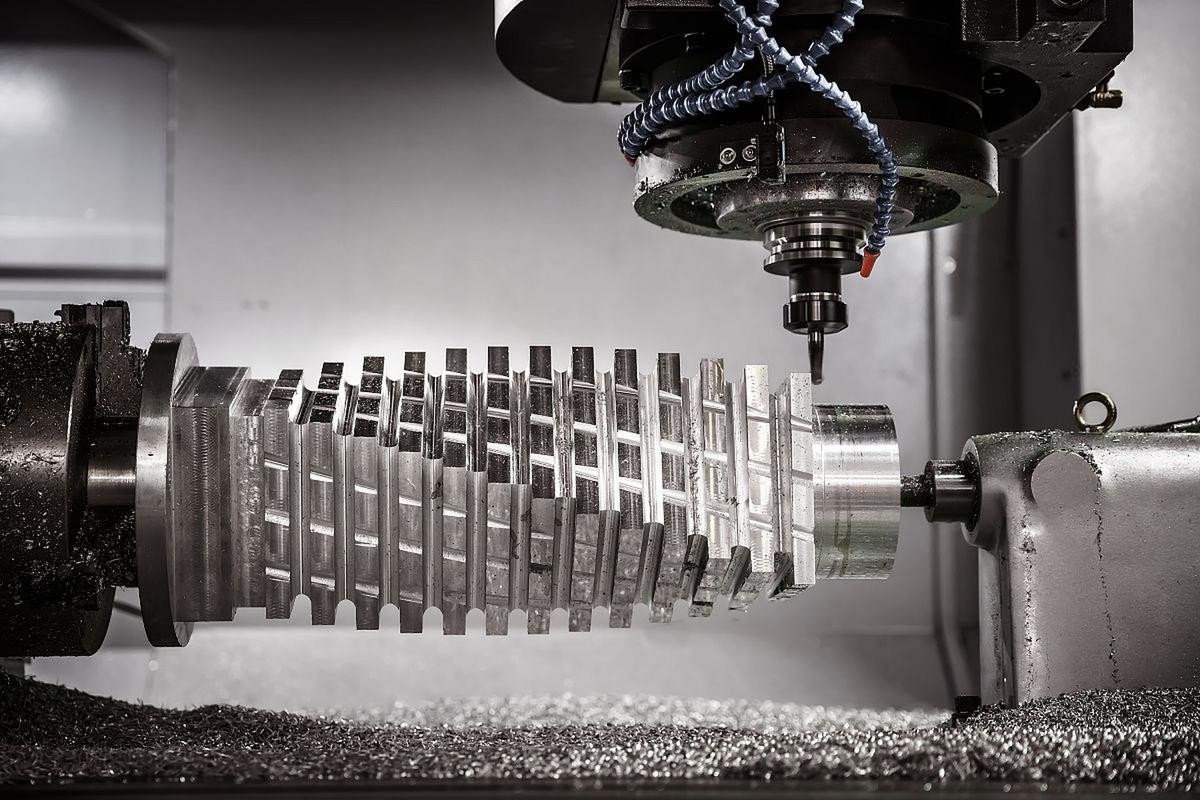

Step 4: Prep Machine & Material (Setup Phase)

- Tool Installation: Mount a 150W fiber laser head (cleaned to remove dust—dust reduces laser efficiency by 15%).

- Material Securing: Use a vacuum table (10,000 Pa suction) to hold the 3mm stainless steel sheet—clamps would leave marks, so vacuum is better for visible parts.

- Calibration: Use a touch probe (accuracy: ±0.001mm) to set the “work offset” (tells the machine: “X=0, Y=0 is the top-left corner of the sheet”). This step takes 2–3 minutes but reduces cutting errors by 60%.

Step 5: Execute the Cut (Automated Phase)

- Press “Cycle Start”—the machine:

-

- Reads G-code line by line (processes 10 lines/second for smooth movement).

-

- Moves the laser head along the programmed path: Cuts the outer shape first, then the holes and slot.

-

- Monitors in real time (closed-loop system): If the laser temperature rises above 40°C, it auto-reduces power by 10% to prevent overheating.

- For 500 brackets:

-

- 1 sheet (20 brackets) takes 8 minutes to cut.

-

- Total cutting time: 200 minutes (3.3 hours)—vs. 16 hours with manual cutting (angle grinders + drills).

Step 6: Post-Cutting Inspection & Finishing

- Inspection (Data-Driven):

-

- Use a digital caliper (accuracy: ±0.01mm) to check hole diameter (must be 6mm ±0.1mm).

-

- Use a surface roughness tester to verify Ra < 1.6μm (pass/fail—parts with Ra >1.6μm are re-deburred).

-

- For 500 brackets: Sample 5% (25 parts)—if 1 fails, inspect 100% (industry standard for quality control).

- Finishing:

-

- Deburr edges with a rotary deburring tool (10 seconds per part) to remove sharp burrs.

-

- Clean parts with ultrasonic cleaning (5 minutes per batch) to remove metal dust (critical for brake parts—dust causes corrosion).

3. Key Q&A: Clarifying Common Questions About the Cutting Process

Q1: Does the cutting process change for different materials?

|

Material

|

Cutting Method

|

Feed Rate

|

Laser Power

|

Cooling Needed?

|

|

3mm Aluminum

|

Fiber Laser

|

300mm/min

|

80W

|

No (low heat)

|

|

3mm Stainless

|

Fiber Laser

|

150mm/min

|

150W

|

Yes (air blast)

|

|

10mm Steel

|

Plasma Cutting

|

80mm/min

|

N/A (arc)

|

Yes (water)

|

Q2: Why do some cutting processes include “air cuts”?

Q3: How long does it take to learn the cutting process?

4. CNC Cutting vs. Traditional Cutting: Process Efficiency Data

|

Metric

|

CNC Fiber Laser Cutting

|

Manual Cutting (Angle Grinder + Drill)

|

|

Total Time

|

3.3 hours

|

16 hours

|

|

Material Waste

|

8%

|

25%

|

|

Defective Parts

|

<1%

|

12%

|

|

Labor Cost

|

$120 (1 operator)

|

$480 (2 operators)

|

|

Tool Wear (Laser Head)

|

5% (lasts 10,000 hours)

|

50% (grinders last 20 hours)

|

5. Common Myths About the Cutting Process (Debunked)

Myth 1: “The cutting process is just ‘pressing a button’.”

Myth 2: “Faster cutting = better.”

Myth 3: “Inspection is optional for simple parts.”

6. Conclusion: Why the CNC Cutting Process Works

- Data ensures parameters (speed, power, tolerance) match the material.

- Standard steps (design → setup → cut → inspect) reduce variation.

- Adaptive systems (closed-loop sensors, auto-cooling) fix issues in real time.