1、Answer

The lifespan of 3D printed molds depends on material and use. Low-temperature thermoplastics (e.g., PLA, ABS) typically last 10–50 cycles for simple, low-pressure applications (e.g., resin casting). High-temperature resins or specialized materials (e.g., Nylon, PETG) can endure 100–500+ cycles for moderate heat/pressure tasks (e.g., injection molding with low-melt plastics), but degrade faster than metal molds.

2、Expansion

Key Factors Influencing Mold Lifespan

-

Material Choice

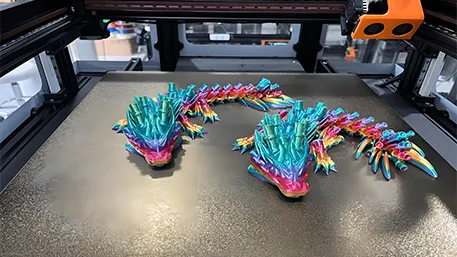

- FDM (Fused Deposition Modeling) Materials:

- PLA/ABS: Cheap and easy to print but brittle and heat-sensitive. Suitable for low-stress applications like small wax or resin casts (e.g., jewelry molds), with lifespans of 10–30 cycles before warping or cracking.

- High-Temp Polymers (e.g., PETG, ASA, Nylon): Resist heat (up to 250°C) and abrasion better. Nylon molds for injection molding may last 50–200 cycles with low-viscosity plastics.

- Resin Printing (SLA/DLP):

- Photopolymer resins offer smoother surfaces and finer details but are prone to chemical erosion from solvents (e.g., in silicone molding). Lifespan: 20–100 cycles for intricate molds (e.g., dental models).

- Industrial-Grade Resins (e.g., high-temperature stereolithography resins): Used for rapid tooling, these can handle 200–500+ cycles in low-pressure injection molding (e.g., prototyping plastic parts).

- FDM (Fused Deposition Modeling) Materials:

-

Mold Design and Geometry

- Complexity: Undercuts, thin walls, or sharp corners increase stress, shortening lifespan. Simple, smooth molds (e.g., straight-wall containers) last longer.

- Surface Finish: Rough surfaces (common in FDM) trap material and accelerate wear. Post-processing (e.g., sanding, coating with epoxy) can extend life by 10–20%.

-

Process Conditions

- Temperature and Pressure:

- Low-heat applications (e.g., room-temperature vulcanizing (RTV) silicone molding) are gentler on molds (up to 50 cycles for PLA).

- High-heat tasks (e.g., injecting molten plastic at 200°C) degrade 3D printed molds rapidly. Even Nylon molds may fail after 100–200 cycles under constant heat and friction.

- Release Agents: Using mold release sprays (e.g., PTFE-based) reduces friction and chemical erosion, adding 10–30% more cycles.

- Temperature and Pressure:

-

Intended Use Case

- Prototyping/Short Runs: 3D printed molds are ideal for low-volume production (e.g., 50–100 parts) in industries like automotive prototyping or artisanal manufacturing.

- Limitations: Not suitable for mass production (metal molds last 10,000+ cycles). For example, a 3D printed injection mold for toy parts might work for 200 samples but fail in factory-scale production.

Practical Applications and Alternatives

- Jewelry Making: A 3D printed wax mold (via SLA) for lost-wax casting can produce 20–50 metal pieces before detail degradation.

- Food Industry: Heat-resistant 3D printed molds (e.g., Nylon for chocolate molding) may last 50–100 uses if cleaned gently and stored at room temperature.

- Hybrid Solutions: Combine 3D printed molds with metal inserts (e.g., steel cores in high-wear areas) to extend lifespan by 2–3x.

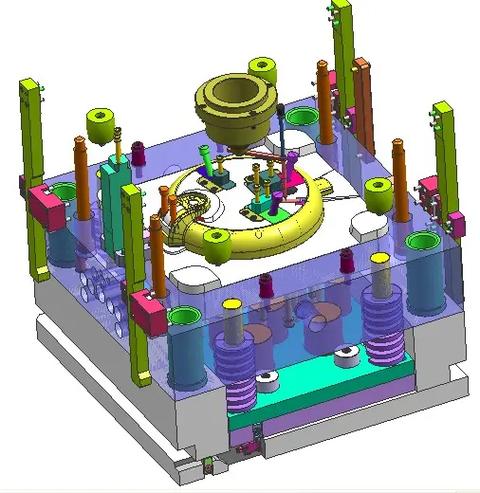

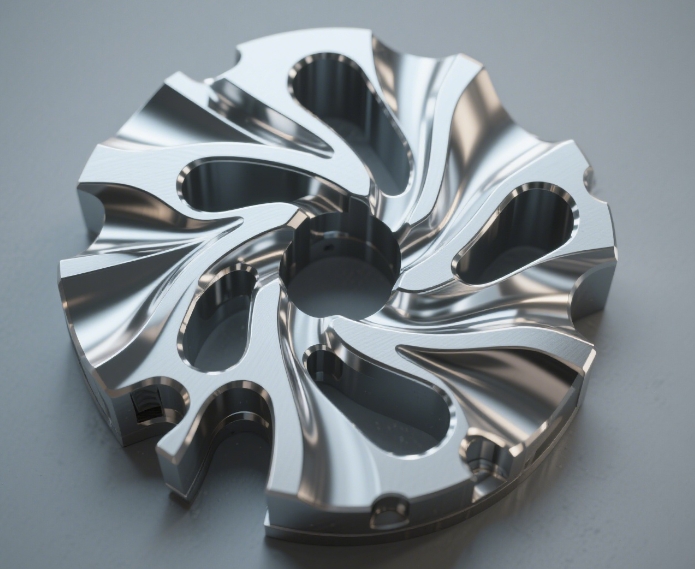

When to Upgrade to Metal Molds

- If production volume exceeds 500–1,000 parts, or if the process requires high precision/heat resistance (e.g., aerospace components), switch to CNC-machined aluminum or steel molds. These offer superior durability (10,000–1,000,000+ cycles) but are cost-prohibitive for small batches.

In summary, 3D printed molds balance cost and speed for low-to-mid-volume needs but require careful material selection and design to maximize their limited lifespan.