Manufacturing a part typically starts with design and prototyping, followed by material selection and choosing a manufacturing process (e.g., CNC machining, casting, or injection molding). The part is then shaped or machined, enhanced via post-processing (heat treatment, surface finishing), and inspected to meet specifications. This process balances design requirements, material properties, and production efficiency.

Detailed Analysis of Part Manufacturing

1. Core Manufacturing Process Steps

Part manufacturing follows a structured workflow to ensure consistency and quality:

-

Design & Prototyping

- Design Phase: Use CAD software (SolidWorks, AutoCAD) to create 3D models, incorporating Design for Manufacturability (DFM) principles to avoid unmachinable features (e.g., overly thin walls <0.5mm). Finite Element Analysis (FEA) simulates stress or heat distribution to optimize geometry—critical for load-bearing parts like automotive brackets.

- Prototyping: 3D printing (FDM, SLA) or CNC machining produces low-volume prototypes to validate fit and function. For example, a plastic phone case prototype uses FDM (ABS) to test ergonomics, while a metal gear prototype uses CNC milling to verify tooth engagement.

-

Material Selection & Preparation

- Materials are chosen based on mechanical needs (strength, flexibility), environment (temperature, corrosion), and cost. For instance:

- Structural parts (e.g., steel beams) use high-strength alloys (A36 steel) for rigidity.

- Lightweight parts (e.g., drone frames) use aluminum (6061) for a balance of strength and weight.

- High-temperature parts (e.g., engine components) use Inconel 718, resisting 1,000°C+ environments.

- Raw materials are prepared as blanks (bars, sheets) or pellets, with pre-processing (e.g., annealing steel to reduce stress) to improve machinability.

- Materials are chosen based on mechanical needs (strength, flexibility), environment (temperature, corrosion), and cost. For instance:

-

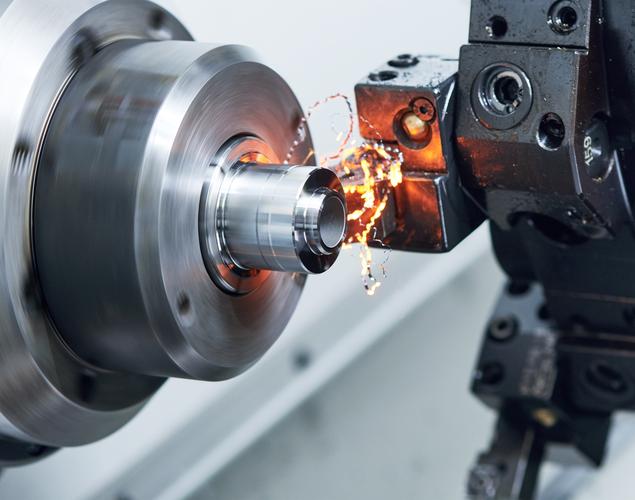

Primary Manufacturing

- CNC Machining: Removes material from solid blanks via milling (3/5-axis) or turning, ideal for metal precision parts (tolerances ±0.001mm). Used for aerospace components (turbine blades) or medical implants (titanium screws).

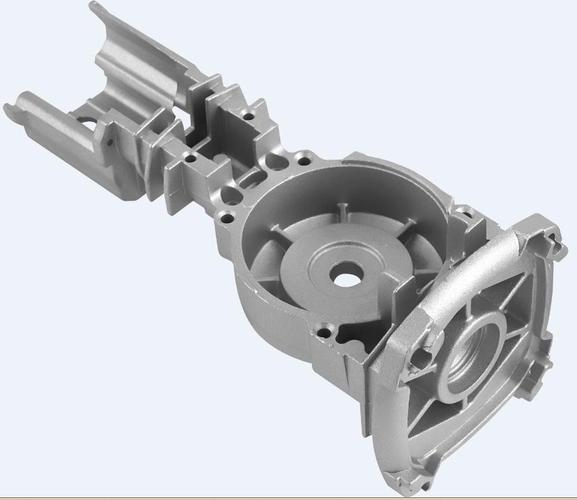

- Casting/Foundry: Molten metal (aluminum, iron) is poured into molds to form complex shapes (e.g., engine blocks). Investment casting achieves fine details (±0.05mm) for jewelry or turbine nozzles.

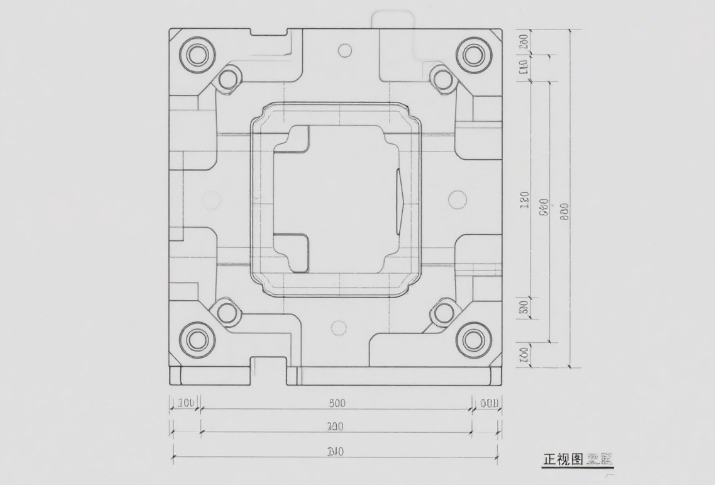

- Injection Molding: Molten plastic (ABS, PC) is injected into molds, producing high-volume parts (e.g., toy components, electronic housings) with cycle times <60 seconds.

- Additive Manufacturing: 3D printers build parts layer-by-layer from metal powders (SLM) or plastics (FFF), suited for low-volume, complex geometries (e.g., custom orthopedic implants with porous structures).

-

Post-Processing

- Mechanical Treatments: Heat treatment (annealing, quenching) strengthens metals (e.g., 4140 steel hardened to 50 HRC). Forging compresses metal to improve grain structure, enhancing fatigue resistance in automotive crankshafts.

- Surface Finishing: Plating (chrome, nickel) resists corrosion; painting or powder coating adds aesthetics (e.g., consumer electronics). Polishing (600-grit sandpaper) achieves Ra <0.8μm for sealing surfaces (hydraulic valves).

-

Quality Control & Inspection

- Dimensional checks use CMMs (±0.0005mm accuracy) or optical scanners to verify compliance with CAD models. Non-destructive testing (ultrasonic, X-ray) detects internal defects in critical parts (e.g., aircraft bolts). For high-volume production, statistical process control (SPC) monitors variation (e.g., ±0.01mm for plastic gears).

2. Key Manufacturing Technologies & Their Applications

Different technologies suit specific part requirements:

-

CNC Machining: Best for high-precision metal parts (tolerances ±0.001–0.01mm) with complex geometries. 5-axis machines handle curved surfaces (e.g., guitar necks), while 3-axis mills produce flat components (e.g., circuit boards). Ideal for low-to-medium volumes (1–10,000 parts).

-

Injection Molding: Dominates high-volume plastic parts (10,000+ units). Molds (steel or aluminum) shape parts like bottle caps or laptop casings, with cycle times as low as 10 seconds. Limited by mold cost ($5,000–$100,000), making it impractical for small batches.

-

Casting: Sand casting (low cost) produces large, rough parts (e.g., manhole covers), while investment casting (high precision) creates detailed components (e.g., turbine blades). Suitable for metals with high melting points (steel, nickel alloys).

-

Additive Manufacturing: 3D printing (SLS, DMLS) excels at complex, low-volume parts (e.g., custom prosthetics, aerospace brackets with internal lattice structures). Eliminates tooling costs but has slower production speeds (1–10 parts/day) compared to molding.

-

Forging: Compresses heated metal to align grain structures, creating high-strength parts (e.g., automotive axles, aerospace fasteners). Hot forging (800–1,200°C) forms large parts, while cold forging (room temperature) achieves tight tolerances (±0.02mm) for bolts.

3. Material Selection Criteria

Material choice depends on part function, environment, and manufacturing process:

-

Metals:

- Steel: Carbon steel (1045) for strength (tensile strength 600 MPa) in structural parts; stainless steel (304) for corrosion resistance in food processing equipment.

- Aluminum: Alloy 6061 (lightweight, 2.7 g/cm³) for aerospace and consumer goods; 7075 (high strength) for sports equipment.

- Titanium (Ti-6Al-4V): High strength-to-weight ratio and biocompatibility, used in medical implants and aircraft parts, despite higher cost.

-

Plastics:

- ABS: Easy to mold, impact-resistant, used in toys and electronics housings.

- PEEK: Heat-resistant (260°C) and chemical-resistant, ideal for medical tools and aerospace components.

- Polypropylene (PP): Flexible and low-cost, used in packaging and automotive trim.

-

Composites:

- Carbon Fiber Reinforced Polymer (CFRP): High strength (1,500 MPa) and low weight (1.6 g/cm³) for aerospace and racing parts, though expensive to manufacture.

- Glass Fiber Reinforced Plastic (GFRP): Cost-effective alternative to CFRP for automotive panels and boat hulls.

4. Industry-Specific Manufacturing Needs

Different sectors demand tailored approaches:

- Automotive: Prioritizes high volume and low cost. Uses stamping (steel body panels), injection molding (plastic interiors), and casting (engine blocks). Tolerances are moderate (±0.05mm) for non-critical parts.

- Aerospace: Requires precision (±0.002mm) and high-performance materials. Relies on CNC machining (titanium parts), forging (landing gear), and composite layup (wing skins) to meet strict safety standards (FAA, EASA).

- Medical Devices: Focuses on biocompatibility and sterility. Uses CNC machining (titanium implants), injection molding (PEEK surgical tools), and 3D printing (custom patient-specific parts like cranial plates).

- Consumer Electronics: Balances aesthetics and cost. Employs injection molding (plastic phone cases), CNC machining (aluminum laptop frames), and anodizing for scratch resistance.

5. Challenges & Solutions in Part Manufacturing

- Small vs. Large Batches: Small batches (1–100 parts) use 3D printing or CNC machining to avoid tooling costs; large batches (>10,000) switch to injection molding or casting for efficiency.

- Precision vs. Cost: High-precision parts (e.g., optical lenses) require ultra-precision CNC (±0.0001mm) and expensive materials, while low-tolerance parts (e.g., brackets) use cost-effective stamping.

- Material-Process Compatibility: For example, brittle materials (ceramics) require powder metallurgy instead of machining; flexible plastics (PVC) use extrusion rather than casting.

- Sustainability: Recycling scrap metal/plastic reduces waste; energy-efficient processes (e.g., low-temperature molding) lower carbon footprints, increasingly important for automotive and consumer goods.

In summary, manufacturing a part integrates design, material science, and process engineering, with each step tailored to meet functional requirements, cost constraints, and industry standards. Success depends on aligning these elements to produce parts that perform reliably in their intended use.