What is a 7 axis CNC machine?

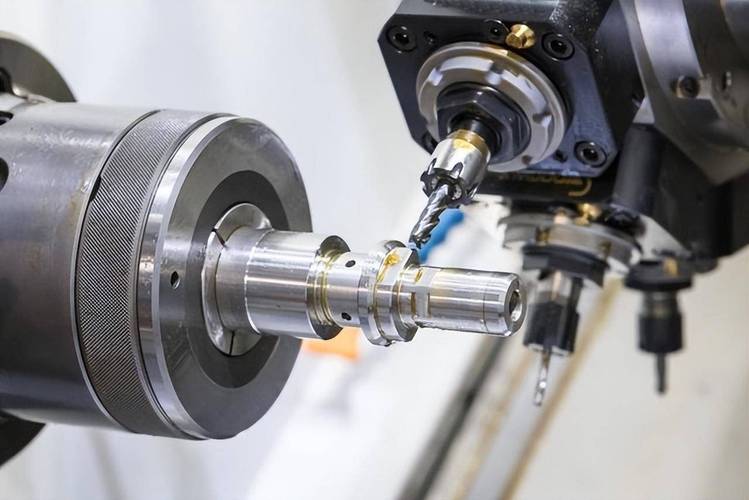

A 7 axis CNC machine is an advanced computer numerical control system that operates with 7 distinct axes of motion,

A 7 axis CNC machine is an advanced computer numerical control system that operates with 7 distinct axes of motion,

In the context of cutting, CNC stands for Computer Numerical Control—a technology that uses computer programs to automate and precision-control

Core Cognition: Why CNC Has Multiple Full Forms When most people hear “CNC,” they think of “Computer Numerical Control”—the foundational

Friends who drive cars are well aware that factory – original parts sometimes are just “adequate but not perfect” –

As motorcycle enthusiasts know, factory – original parts always seem to lack that certain “oomph” – either their performance can’t

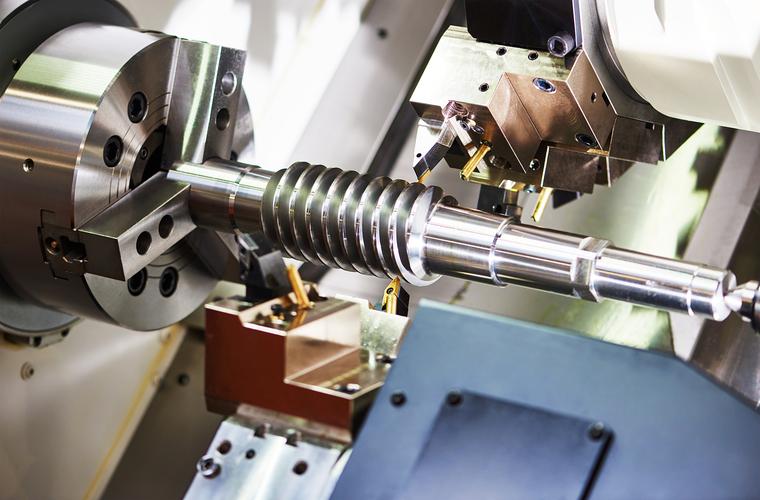

CNC thread machining is a process that uses programmed instructions to control CNC machines, utilizing specialized tools (such as taps

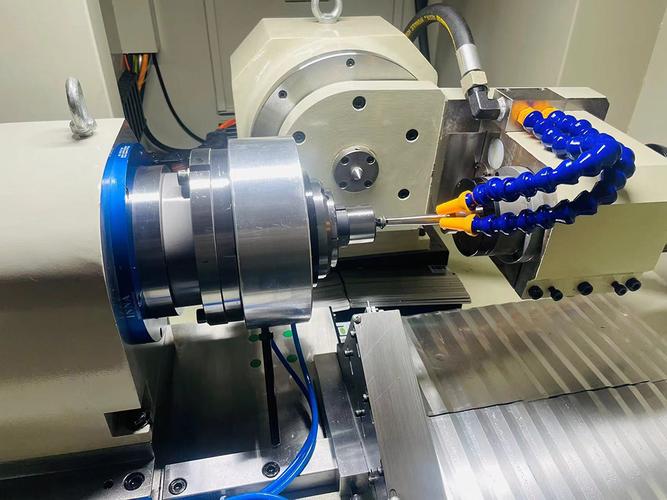

CNC programming involves creating a set of instructions (G-code/M-code) that guide a CNC machine to produce a part. The process

The core principle of CNC (Computer Numerical Control) machines is automated, precise control of tool or workpiece movements using preprogrammed

CNC, short for Computer Numerical Control, is a manufacturing technology that uses preprogrammed digital instructions to automate the operation of

A CNC (Computer Numerical Control) system is the “brain” that automates machine tools, translating digital instructions into precise physical movements.

CNC (Computer Numerical Control) machines automate manufacturing by following programmed instructions to shape materials like metal, plastic, or wood. Their

Injection molding and plastic casting are both methods to shape plastic, but they differ fundamentally in how material is introduced